| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

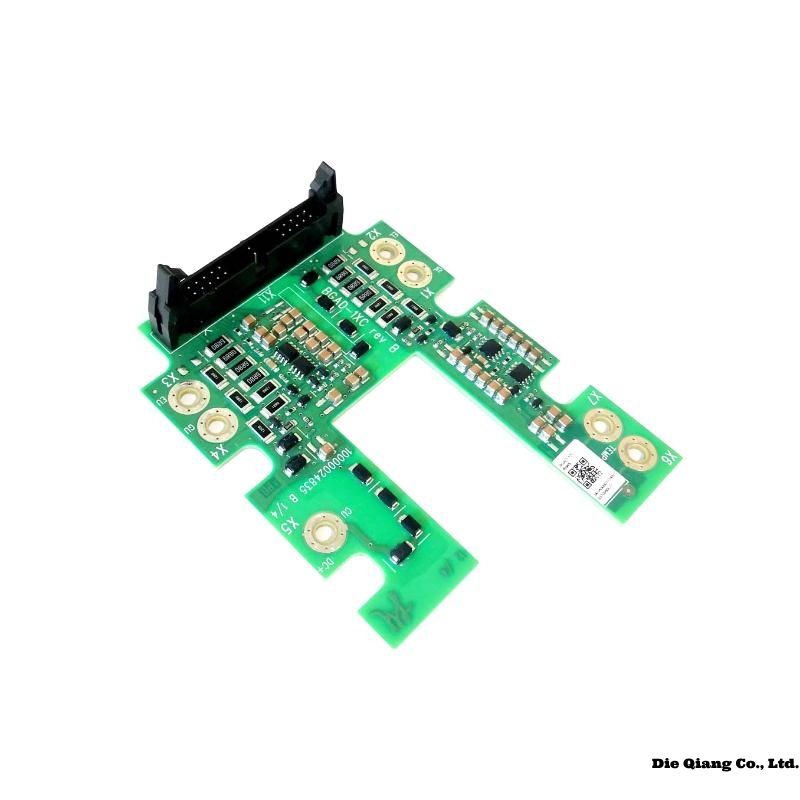

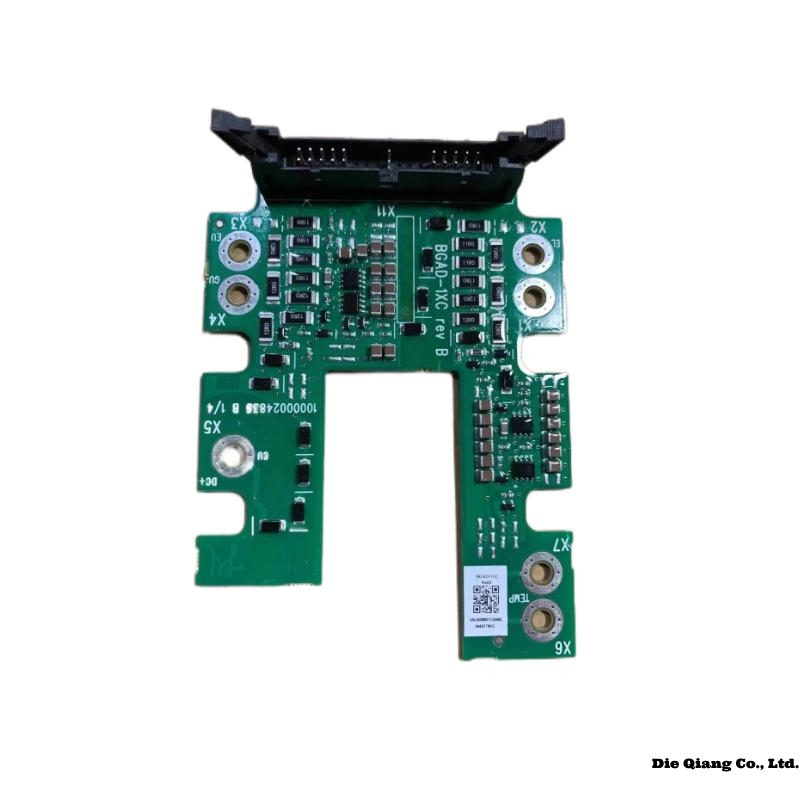

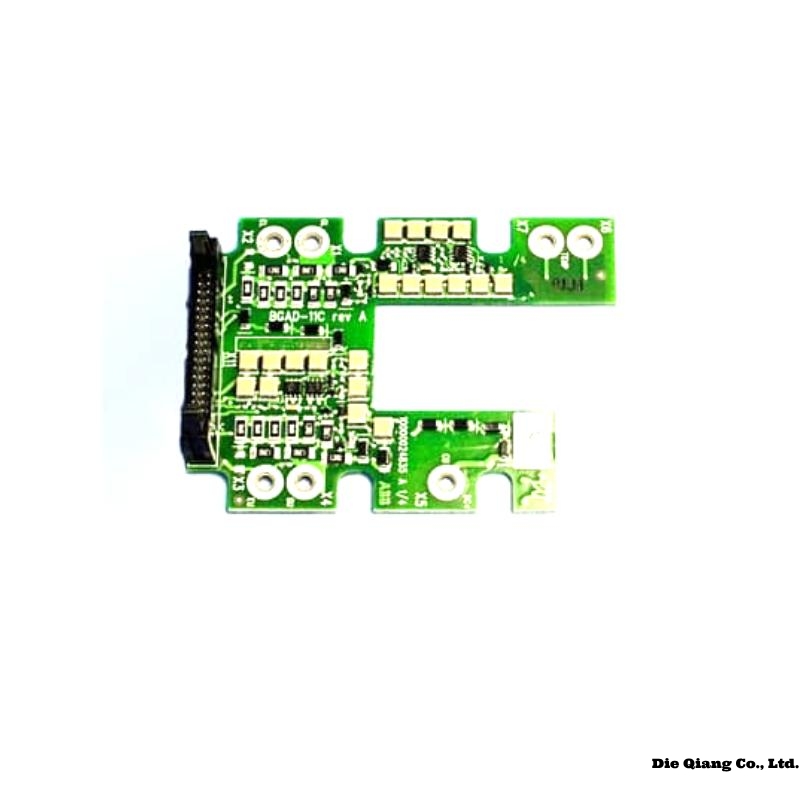

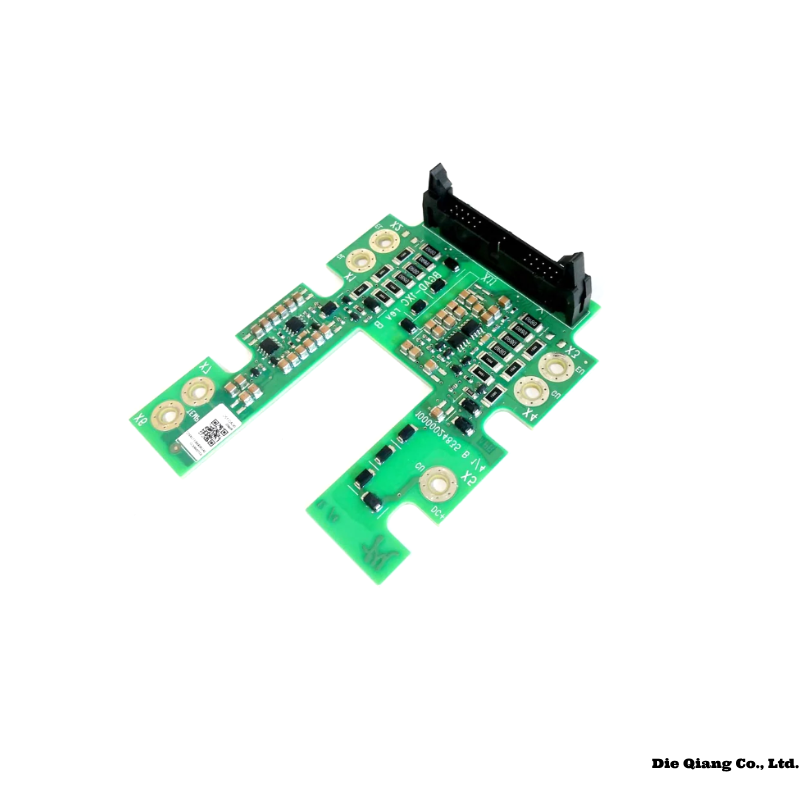

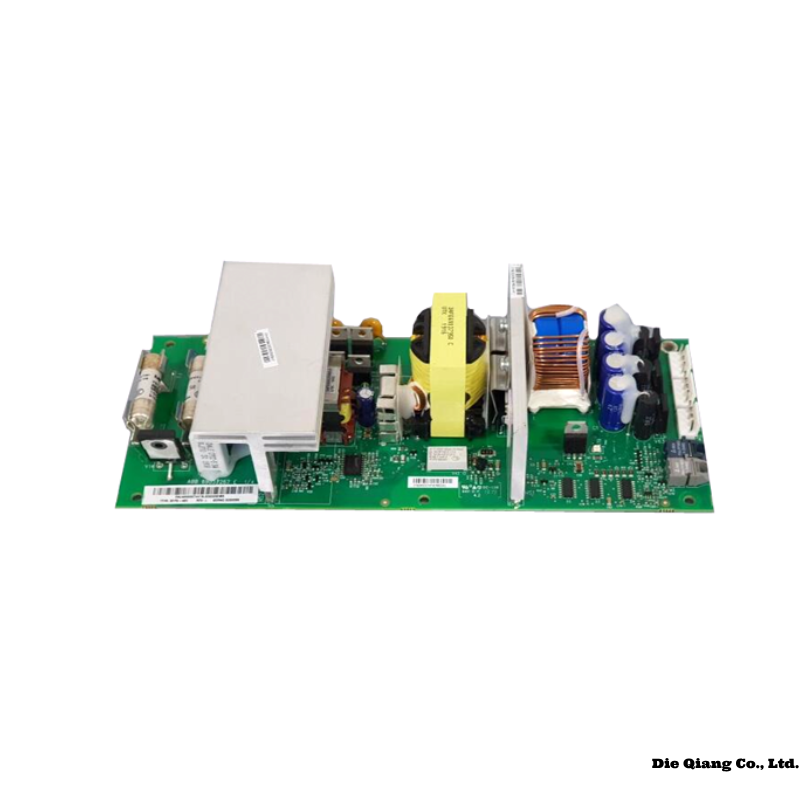

Product Introduction – ABB BGAD-12C (3AUA0000112491)

The ABB BGAD-12C (Part No. 3AUA0000112491) is a high-performance braking chopper module designed for use in ABB’s ACS800 drive series and other compatible AC drive systems. Engineered for medium to high power industrial applications, the BGAD-12C is responsible for safely dissipating regenerative energy during motor braking cycles. It ensures efficient energy management and protection of the drive components by redirecting excess voltage to external braking resistors.

This braking unit is vital in dynamic applications such as cranes, elevators, conveyors, and centrifuges, where rapid deceleration can generate high levels of regenerative energy. ABB’s BGAD-12C offers exceptional reliability, compact design, and seamless integration into ABB’s automation and drive solutions.

Product Advantages

-

High Energy Dissipation Capability

Capable of handling high braking power, making it ideal for demanding dynamic load applications. -

Seamless Integration

Designed for compatibility with ABB ACS800 series drives, reducing engineering and installation complexity. -

Compact Design

The space-saving construction allows for efficient cabinet integration. -

Overvoltage Protection

Ensures the drive system remains within safe operational voltage limits during regenerative braking. -

Robust and Durable

Built with industrial-grade materials for long-term stability under harsh operating conditions. -

Simple Installation and Maintenance

Comes with mounting and wiring instructions that streamline installation and minimize downtime.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Model | BGAD-12C |

| ABB Part Number | 3AUA0000112491 |

| Voltage Rating | 600 V DC nominal |

| Braking Power Capacity | Up to 12 kW |

| Dimensions (H x W x D) | 330 mm x 250 mm x 150 mm |

| Weight | 4.2 kg |

| Operating Temperature | -10°C to +50°C |

| Storage Temperature | -40°C to +70°C |

| Cooling Method | Natural air cooling |

| Mounting Type | Panel-mounted |

| Protection Class | IP20 |

| Compatible Drives | ABB ACS800 series |

| Certification | CE, UL, RoHS |

Product Applications

-

Elevator Systems – Controls braking energy in lifting applications, providing smooth operation and safety.

-

Cranes and Hoists – Manages regenerative energy during lifting/lowering loads, preventing voltage surges.

-

Centrifuges and Spinners – Handles high deceleration torque where braking demand is frequent.

-

Conveyor Systems – Maintains motor control efficiency during frequent starts/stops in production lines.

-

Machine Tools – Supports rapid deceleration cycles in cutting, milling, and drilling equipment.

-

Winders/Unwinders – Manages braking energy for systems dealing with reel tension.

Compatible Models / Associated Products

-

ACS800-01 – Wall-mounted drive series.

-

ACS800-02 – Cabinet-built drive with high customization.

-

ACS800-04 – Single drive modules for cabinet assembly.

-

ACS800-07 – Free-standing drive modules with power regeneration.

-

DBR-1500 – Dynamic braking resistor designed for pairing with BGAD-12C.

-

REX 521 – Control relay that can be used in conjunction with drive protection.

Installation Instructions

-

Pre-installation Checklist

Ensure the main drive power is turned off. Verify compatibility between the drive and BGAD-12C braking chopper. Mount in a well-ventilated panel. -

Mechanical Mounting

Secure the unit vertically onto a metal mounting plate using standard screws. Allow adequate spacing around the device for ventilation (minimum 100 mm clearance on all sides). -

Wiring Connections

Connect the DC bus terminals from the drive to the BGAD-12C input terminals. Ensure correct polarity and tight torque application to avoid arcing. -

Braking Resistor Connection

Connect the external braking resistor to the designated terminals. Match the resistor’s power rating to the braking energy requirements. -

Testing

After powering up the drive system, perform a test braking cycle under no-load conditions to confirm correct operation. -

Safety Measures

Always ground the unit properly. Verify thermal protection is functional. Keep away from moisture and dust ingress.

6 Related Models from the Same or Similar Series

| Model | Part Number | Voltage Rating | Braking Power | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| BGAD-05C | 3AUA0000112485 | 600 V DC | 5 kW | 290 x 200 x 120 | 3.2 |

| BGAD-08C | 3AUA0000112488 | 600 V DC | 8 kW | 310 x 230 x 140 | 3.8 |

| BGAD-16C | 3AUA0000112492 | 600 V DC | 16 kW | 350 x 270 x 160 | 5.0 |

| BGAD-20C | 3AUA0000112494 | 600 V DC | 20 kW | 380 x 300 x 180 | 6.2 |

| BGAD-25C | 3AUA0000112496 | 600 V DC | 25 kW | 400 x 320 x 200 | 7.0 |

| BGAD-30C | 3AUA0000112498 | 600 V DC | 30 kW | 430 x 350 x 220 | 8.5 |

8 Popular ABB Models

| Model | Part Number | Description | Voltage | Power Rating | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| ACS880-01-07A3-3 | 3AXD50000038974 | Wall-mounted single drive | 400 V AC | 4 kW | 530 x 250 x 270 | 15 |

| ACS800-01-0010-3 | 68654778 | General-purpose industrial drive | 400 V AC | 7.5 kW | 500 x 300 x 200 | 20 |

| PSE142-600-70 | 1SFA897110R7000 | Softstarter with torque control | 600 V AC | 75 kW | 380 x 210 x 180 | 6.4 |

| ACS355-03E-07A3-4 | 3AUA0000058188 | Machinery drive | 480 V AC | 3 kW | 330 x 110 x 150 | 3.5 |

| ACS550-01-023A-4 | 3AUA0000046473 | HVAC drive for commercial systems | 480 V AC | 11 kW | 420 x 180 x 220 | 9.2 |

| DCS880-S01-0415-05 | 3AXD50000021135 | DC industrial drive | 500 V DC | 415 A | 750 x 400 x 280 | 26 |

| MNS-MCC | N/A | Motor Control Center (Modular System) | 690 V AC | Up to 3200 A | Customizable | Varies |

| ACS580-01-07A6-4 | 3AUA0000170292 | General-purpose drive with built-in EMC | 400 V AC | 4 kW | 390 x 210 x 195 | 6.7 |

Frequently Asked Questions (FAQ)

Q1: What is the purpose of the ABB BGAD-12C braking chopper?

A1: The BGAD-12C is designed to absorb and safely dissipate excess regenerative energy during motor deceleration, preventing overvoltage damage to the drive system.

Q2: Can the BGAD-12C be used with non-ABB drives?

A2: While it is optimized for ABB ACS800 series drives, it may be used with other drives that support DC link braking choppers, provided the voltage and power ratings match.

Q3: What size braking resistor should be used with the BGAD-12C?

A3: The braking resistor size depends on the braking power and duty cycle. ABB typically recommends resistors rated equal to or greater than the chopper’s rated braking power—12 kW in this case.

Q4: How should the BGAD-12C be protected from overheating?

A4: Ensure proper ventilation during installation. Thermal sensors may be installed if the operating environment is subject to high ambient temperatures or continuous braking cycles.

Q5: Is regular maintenance required for the BGAD-12C?

A5: Minimal maintenance is needed. Periodic visual inspections for dust accumulation, loose wiring, and thermal discoloration are recommended to ensure safe operation.

Q6: What are the safety precautions before installation?

A6: Always disconnect power before installation. Use proper grounding, avoid moisture-prone areas, and ensure that all connections comply with electrical safety standards.

ABB BGAD-12C 3AUA0000112491 Inverter accessories

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||