| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

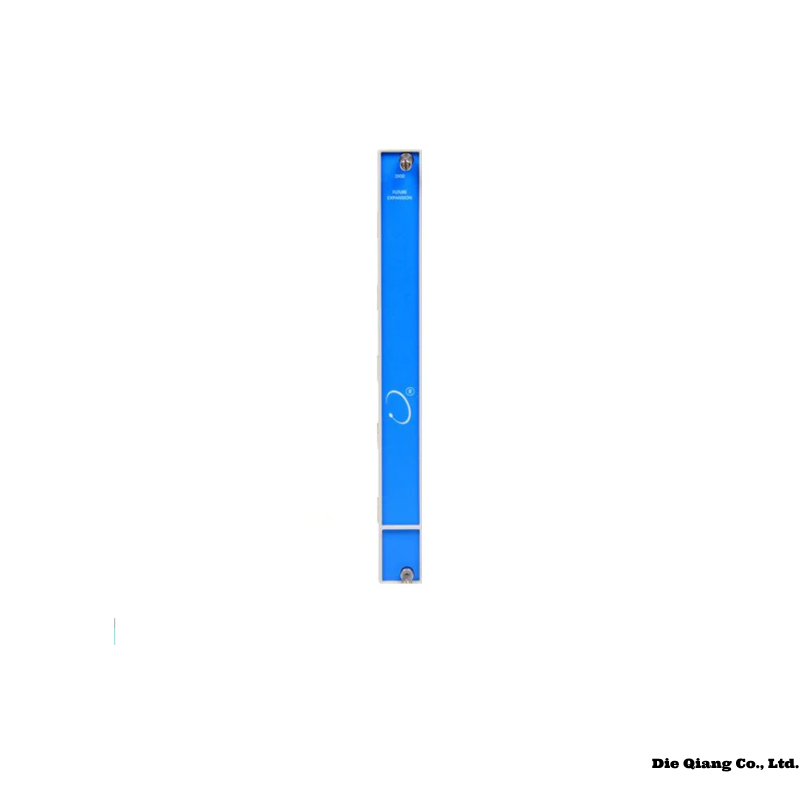

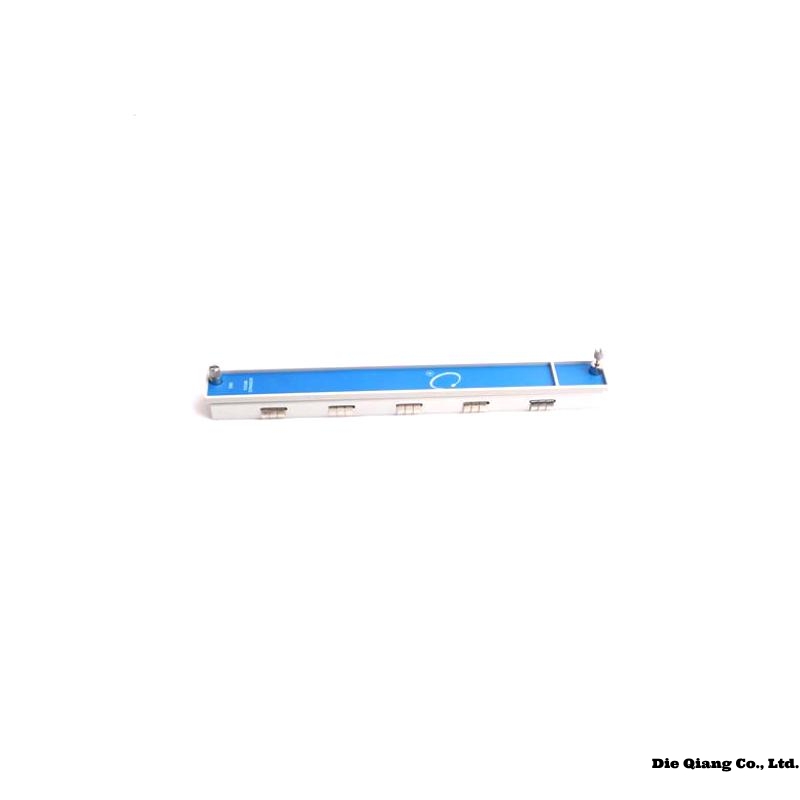

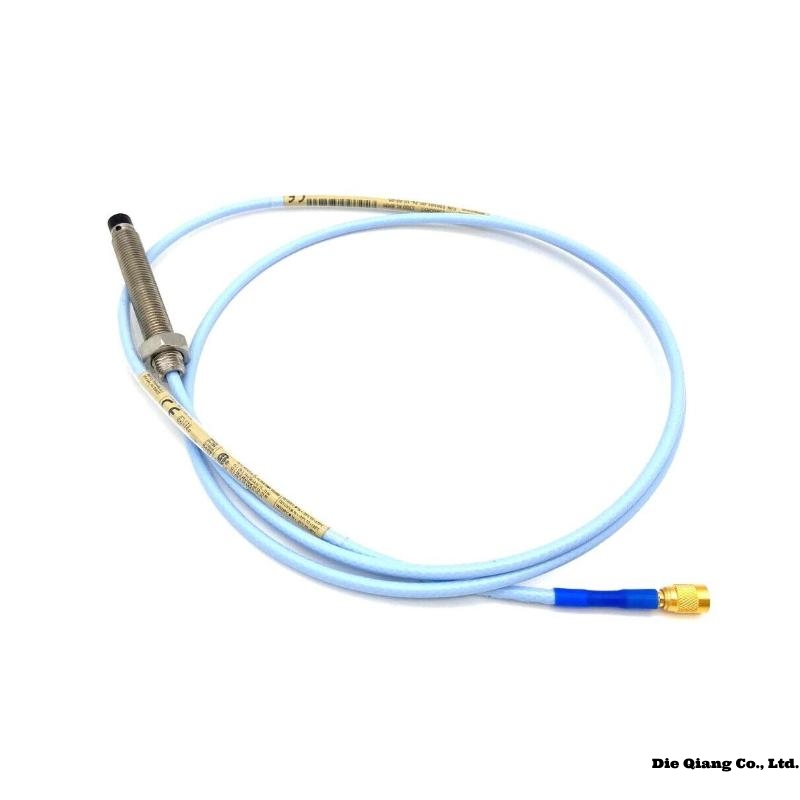

Product Introduction: Bently 128275-01

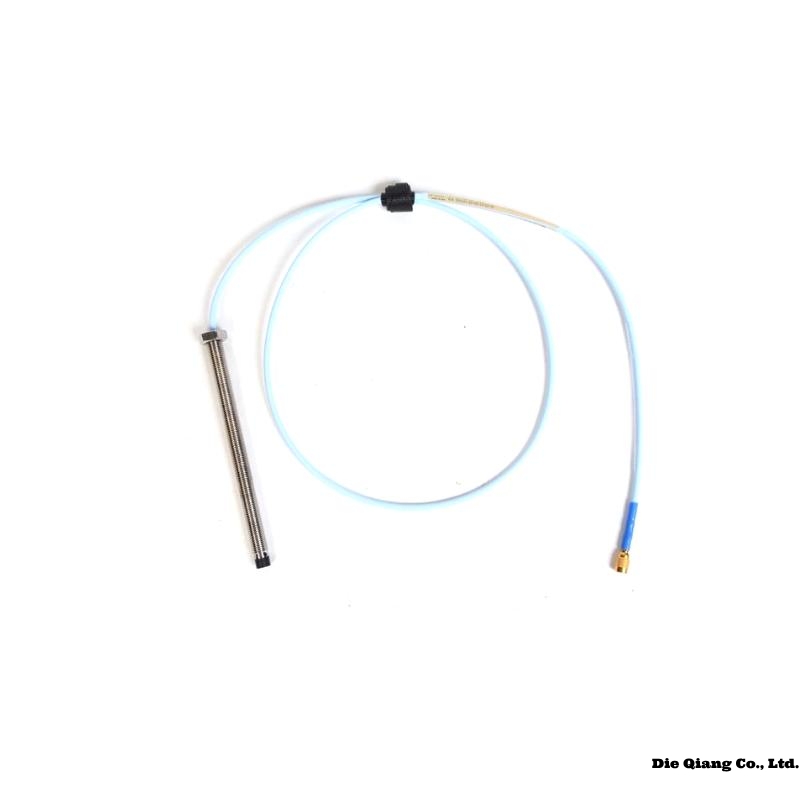

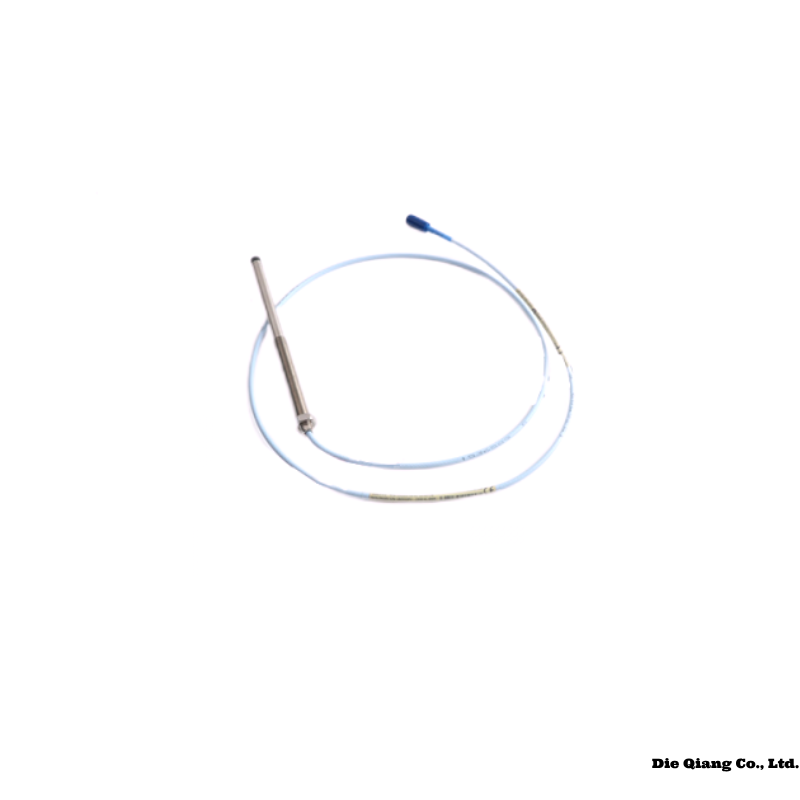

The Bently 128275-01 is a high-performance monitoring module designed for industrial applications. It is part of the Bently Nevada series, renowned for its reliability and precision in machinery protection and condition monitoring. This module is specifically engineered to provide accurate vibration and position measurements, ensuring optimal performance and safety of rotating machinery.

The Bently 128275-01 is ideal for use in various industries, including oil and gas, power generation, and manufacturing. Its robust design and advanced features make it a critical component in predictive maintenance strategies, helping to prevent unexpected downtime and costly repairs.

Product Advantages

- High Accuracy: The module offers precise measurement capabilities, ensuring reliable data for machinery health assessment.

- Durability: Built to withstand harsh industrial environments, it features a rugged design that resists dust, moisture, and temperature fluctuations.

- Ease of Integration: The module is compatible with a wide range of monitoring systems, making it easy to integrate into existing setups.

- Advanced Diagnostics: It includes advanced diagnostic features that help identify potential issues before they escalate.

- Low Maintenance: Designed for long-term use with minimal maintenance requirements, reducing operational costs.

- Compliance: Meets international standards for industrial safety and performance.

Technical Parameters

| Parameter | Value |

|---|---|

| Dimensions | 150mm x 100mm x 50mm |

| Weight | 0.5 kg |

| Operating Voltage | 24V DC |

| Input Voltage Range | 18V – 30V DC |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Vibration Range | 0-20 mm/s |

| Position Range | 0-2 mm |

| Output Signal | 4-20 mA |

| Communication Protocol | Modbus RTU |

| Enclosure Rating | IP67 |

Product Applications

The Bently 128275-01 is widely used in industries where machinery health monitoring is critical. Its primary applications include:

- Oil and Gas: Monitoring pumps, compressors, and turbines to ensure safe and efficient operations.

- Power Generation: Protecting generators, steam turbines, and gas turbines from unexpected failures.

- Manufacturing: Ensuring the reliability of rotating equipment such as motors, fans, and conveyors.

- Chemical Processing: Monitoring mixers, reactors, and other critical machinery in hazardous environments.

- Water Treatment: Protecting pumps and blowers in water and wastewater treatment plants.

Compatible Models

The Bently 128275-01 is designed to work seamlessly with the following models:

- Bently 3500/22M: Transient Data Interface Module.

- Bently 3500/42M: Proximitor Seismic Monitor.

- Bently 3300/16: Proximity Transducer System.

- Bently 3300/25: Accelerometer Monitor.

- Bently 3300/50: 4-Channel Relay Module.

Installation Instructions

- Preparation: Ensure the power supply is turned off before installation. Verify that the mounting surface is clean and secure.

- Mounting: Use the provided screws to mount the module on a DIN rail or flat surface. Ensure proper alignment.

- Wiring: Connect the input and output signals according to the wiring diagram provided in the manual. Ensure all connections are tight and secure.

- Power Connection: Connect the power supply to the designated terminals, ensuring the voltage matches the module’s requirements.

- Testing: Power on the system and verify that the module is functioning correctly. Use diagnostic tools to check signal output.

- Calibration: Perform initial calibration using the recommended procedures to ensure accurate measurements.

Recommended Models in the Same Series

| Model Number | Description | Dimensions | Weight | Voltage | Key Features |

|---|---|---|---|---|---|

| Bently 128275-02 | Enhanced Vibration Monitor | 150mm x 100mm x 50mm | 0.5 kg | 24V DC | Higher vibration range, advanced diagnostics |

| Bently 128275-03 | Dual-Channel Position Monitor | 150mm x 100mm x 50mm | 0.6 kg | 24V DC | Dual-channel input, Modbus RTU |

| Bently 128275-04 | High-Temperature Monitor | 150mm x 100mm x 50mm | 0.55 kg | 24V DC | Operates up to 100°C, rugged design |

| Bently 128275-05 | Wireless Monitoring Module | 150mm x 100mm x 50mm | 0.5 kg | 24V DC | Wireless communication, easy setup |

| Bently 128275-06 | Multi-Parameter Monitor | 150mm x 100mm x 50mm | 0.65 kg | 24V DC | Monitors vibration, temperature, and position |

| Bently 128275-07 | Compact Vibration Monitor | 120mm x 80mm x 40mm | 0.4 kg | 24V DC | Space-saving design, high accuracy |

Popular Models from the Same Brand

| Model Number | Description | Dimensions | Weight | Voltage | Key Features |

|---|---|---|---|---|---|

| Bently 3500/22M | Transient Data Interface | 200mm x 150mm x 60mm | 1.2 kg | 24V DC | High-speed data acquisition |

| Bently 3500/42M | Proximitor Seismic Monitor | 200mm x 150mm x 60mm | 1.3 kg | 24V DC | Seismic and proximity monitoring |

| Bently 3300/16 | Proximity Transducer System | 180mm x 120mm x 50mm | 1.0 kg | 24V DC | Reliable proximity sensing |

| Bently 3300/25 | Accelerometer Monitor | 180mm x 120mm x 50mm | 1.1 kg | 24V DC | Vibration and acceleration monitoring |

| Bently 3300/50 | 4-Channel Relay Module | 180mm x 120mm x 50mm | 1.0 kg | 24V DC | Multi-channel relay outputs |

| Bently 1900/65A | Speed Sensor | 100mm x 50mm x 30mm | 0.3 kg | 24V DC | High-precision speed measurement |

| Bently 2300/25 | Temperature Monitor | 150mm x 100mm x 50mm | 0.7 kg | 24V DC | Temperature monitoring and control |

| Bently 7200 | Vibration Transmitter | 120mm x 80mm x 40mm | 0.5 kg | 24V DC | Compact vibration monitoring |

FAQ (Frequently Asked Questions)

Q1: What is the operating temperature range of the Bently 128275-01?

A1: The operating temperature range is -20°C to +70°C.

Q2: Can the Bently 128275-01 be used in hazardous environments?

A2: Yes, it is designed to withstand harsh industrial environments and has an IP67 enclosure rating.

Q3: What communication protocol does the module support?

A3: It supports Modbus RTU for seamless integration with monitoring systems.

Q4: Is calibration required after installation?

A4: Yes, initial calibration is recommended to ensure accurate measurements.

Q5: Can the module monitor both vibration and position?

A5: Yes, it is capable of monitoring both vibration and position parameters.

Q6: What is the warranty period for the Bently 128275-01?

A6: The standard warranty period is 24 months from the date of purchase.

Bently Nevada 128275-01 Future expansion

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||