| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

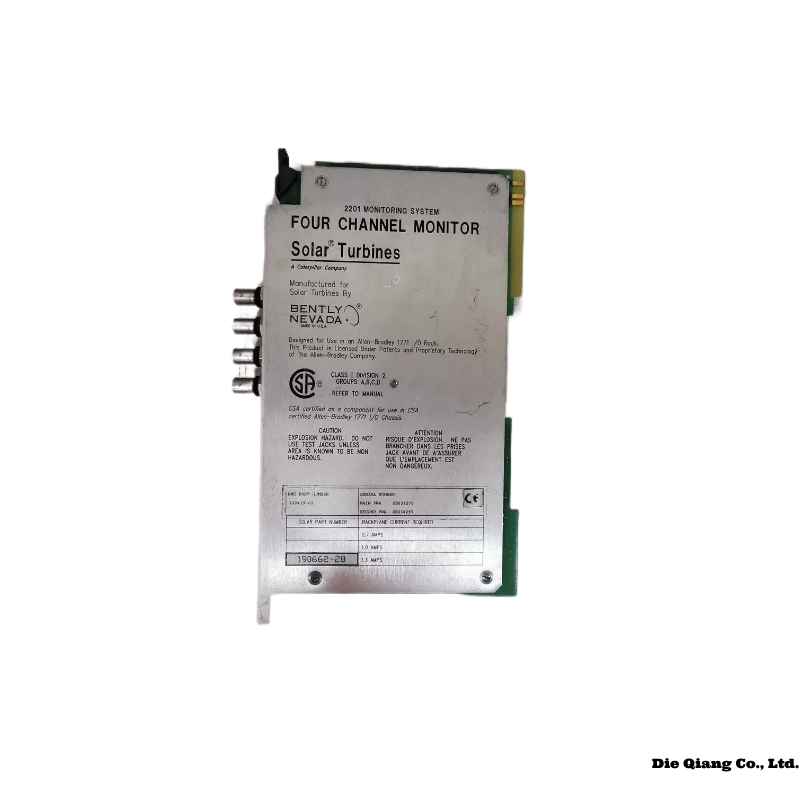

Bently Nevada 132419-01 190662-28 Product Overview

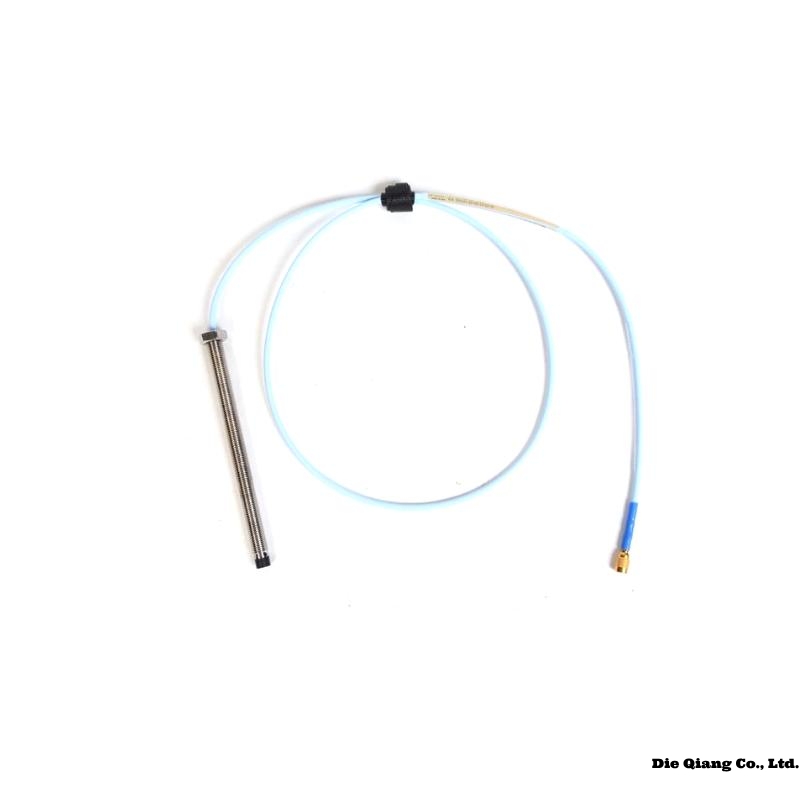

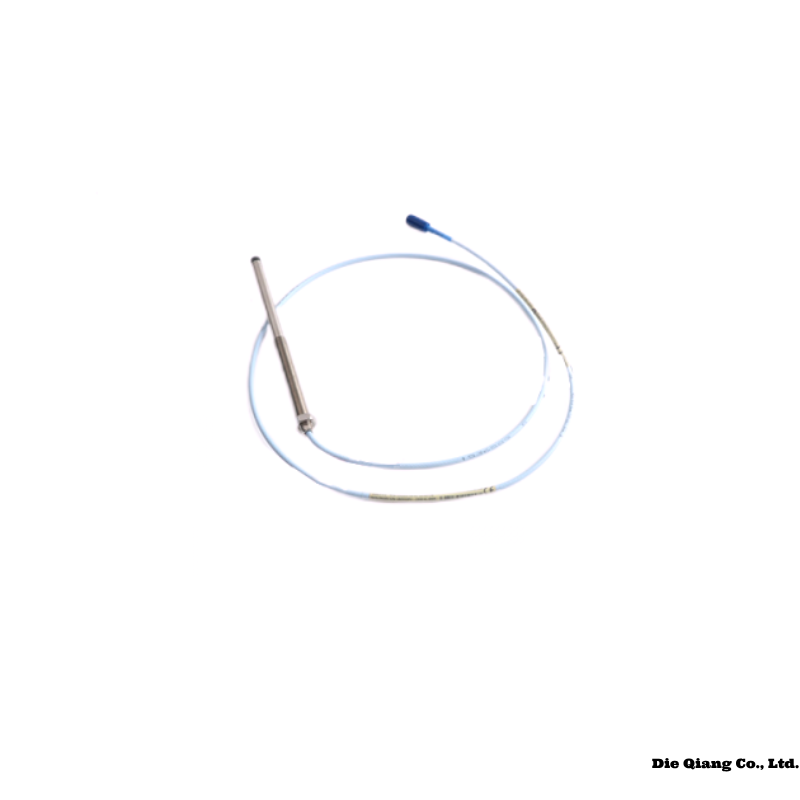

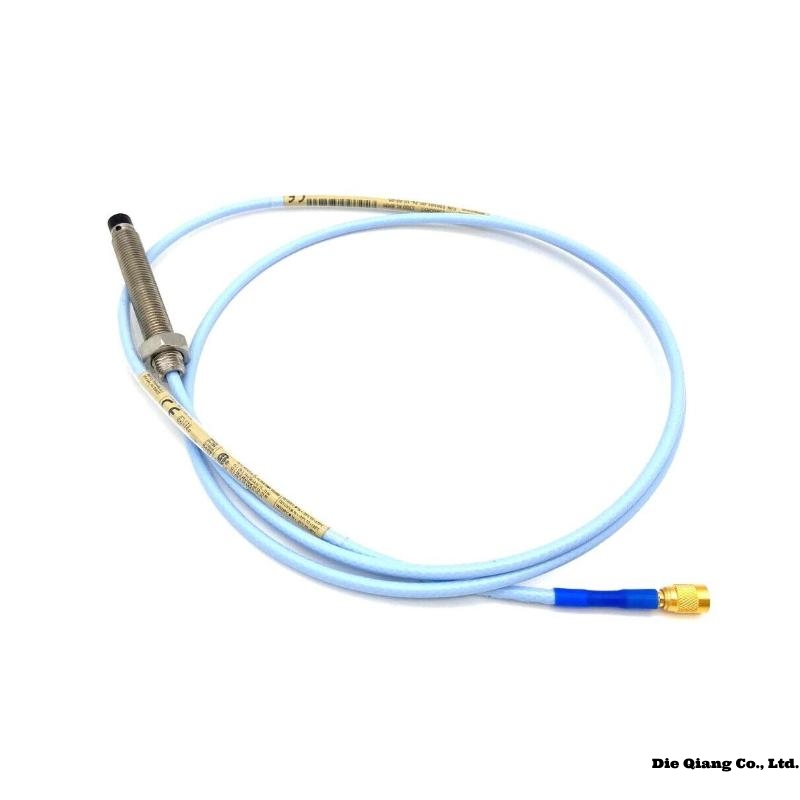

The Bently Nevada 132419-01 190662-28 is a high-performance monitoring module designed for industrial machinery protection and condition monitoring. It is part of the Bently Nevada 3500 Series, a widely recognized system for machinery health management in critical applications. This module ensures reliable vibration, speed, and position monitoring, helping to prevent equipment failures and optimize operational efficiency.

Product Advantages

- High Reliability – Engineered for continuous operation in harsh industrial environments, ensuring long-term stability.

- Advanced Diagnostics – Provides real-time data and fault detection to minimize downtime.

- Modular Design – Easily integrates with the 3500 Series framework for flexible system configuration.

- Compliance with Industry Standards – Meets global safety and performance certifications.

- User-Friendly Interface – Simplifies setup and maintenance with intuitive software tools.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 132419-01 190662-28 |

| Dimensions | 241 x 24.4 x 99.1 mm |

| Weight | 0.75 kg |

| Operating Voltage | 24 VDC (±10%) |

| Input Channels | 4 (Dual-Keyphasor® capable) |

| Frequency Range | 0.5 Hz to 15 kHz |

| Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Communication | RS-485, Modbus protocol |

| Enclosure Rating | IP67 (Dust and water-resistant) |

Applications

The 132419-01 190662-28 is widely used in:

- Gas & Steam Turbines – For vibration and speed monitoring.

- Compressors & Pumps – Ensures safe operation under high-load conditions.

- Power Generation – Protects critical assets in nuclear and fossil fuel plants.

- Oil & Gas – Monitors offshore and onshore rotating equipment.

Compatible Models

This module works seamlessly with:

- 3500/22M Transient Data Interface

- 3500/42M Proximitor® Monitor

- 3500/53 16-Channel Relay Module

- 3500/92 Communication Gateway

Installation Instructions

- Mounting – Secure the module in a 3500 Series rack using the provided slots.

- Wiring – Connect input signals (sensors) and power supply per the wiring diagram.

- Configuration – Use the 3500 Configuration Software to set parameters.

- Testing – Verify signal integrity and alarm thresholds before operation.

- Documentation – Record settings for future maintenance.

Recommended Related Models (Same Series)

| Model | Function | Dimensions | Weight | Voltage |

|---|---|---|---|---|

| 3500/42M | Proximitor Monitor | 8.5 x 5.2 x 1.8 in | 2.2 lbs | 24 VDC |

| 3500/22M | Transient Data Interface | 8.5 x 5.2 x 1.8 in | 2.2 lbs | 24 VDC |

| 3500/53 | 16-Channel Relay Module | 8.5 x 5.2 x 1.8 in | 2.2 lbs | 24 VDC |

| 3500/92 | Communication Gateway | 8.5 x 5.2 x 1.8 in | 2.2 lbs | 24 VDC |

| 3500/15 | Power Supply Module | 8.5 x 5.2 x 1.8 in | 2.2 lbs | 120/240 VAC |

| 3500/25 | TMR (Triple Modular Redundancy) | 8.5 x 5.2 x 1.8 in | 2.2 lbs | 24 VDC |

Popular Bently Nevada Models (Other Series)

| Model | Function | Dimensions | Weight | Voltage |

|---|---|---|---|---|

| 3300/16 | Proximity Transducer System | 3.5 x 2.0 x 1.2 in | 0.5 lbs | 18-30 VDC |

| 3300/25 | Accelerometer Monitor | 3.5 x 2.0 x 1.2 in | 0.5 lbs | 18-30 VDC |

| 1900/65A | Seismic Monitoring System | 6.0 x 4.0 x 2.0 in | 1.5 lbs | 24 VDC |

| 2300/25 | Vibration Monitor | 5.0 x 3.5 x 1.5 in | 1.0 lbs | 24 VDC |

| 3701/25 | Machinery Health Monitor | 8.5 x 5.2 x 1.8 in | 2.2 lbs | 24 VDC |

| 1900/27 | Dual-Channel Monitor | 6.0 x 4.0 x 2.0 in | 1.5 lbs | 24 VDC |

| 2300/20 | Speed Monitor | 5.0 x 3.5 x 1.5 in | 1.0 lbs | 24 VDC |

| 3701/20 | Condition Monitoring System | 8.5 x 5.2 x 1.8 in | 2.2 lbs | 24 VDC |

FAQ (Q&A)

Q1: What is the primary function of the 132419-01 190662-28 module?

A1: It is a 4-channel monitoring module for vibration, speed, and position sensing in industrial machinery.

Q2: Can this module operate in explosive environments?

A2: Yes, it is ATEX/IECEx certified for hazardous areas when installed correctly.

Q3: What software is needed for configuration?

A3: The Bently Nevada 3500 Configuration Software is required for setup.

Q4: Is the module compatible with third-party sensors?

A4: It supports industry-standard sensors but optimal performance is achieved with Bently Nevada probes.

Q5: What is the typical lifespan of this module?

A5: With proper maintenance, it can last 10+ years in industrial settings.

Q6: How do I troubleshoot communication errors?

A6: Check RS-485 wiring, baud rate settings, and Modbus address conflicts.

Bently Nevada 132419-01 190662-28 4Channel Monitor Solar Turbines

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

132419-01, 190662-28, 4Channel Monitor Solar Turbines, Bently Nevada, Bently Nevada 132419-01 190662-28