| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

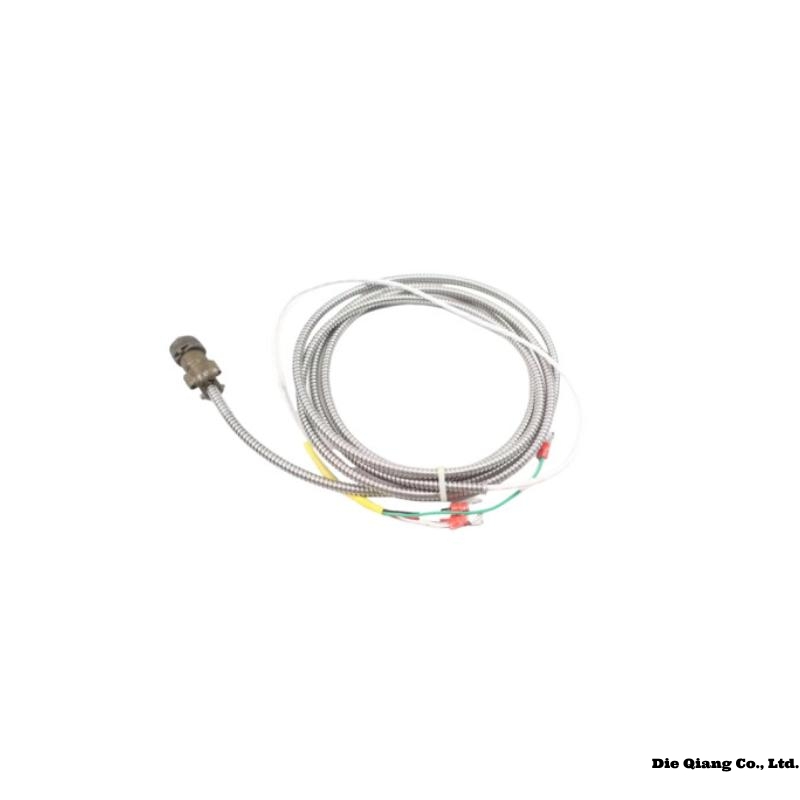

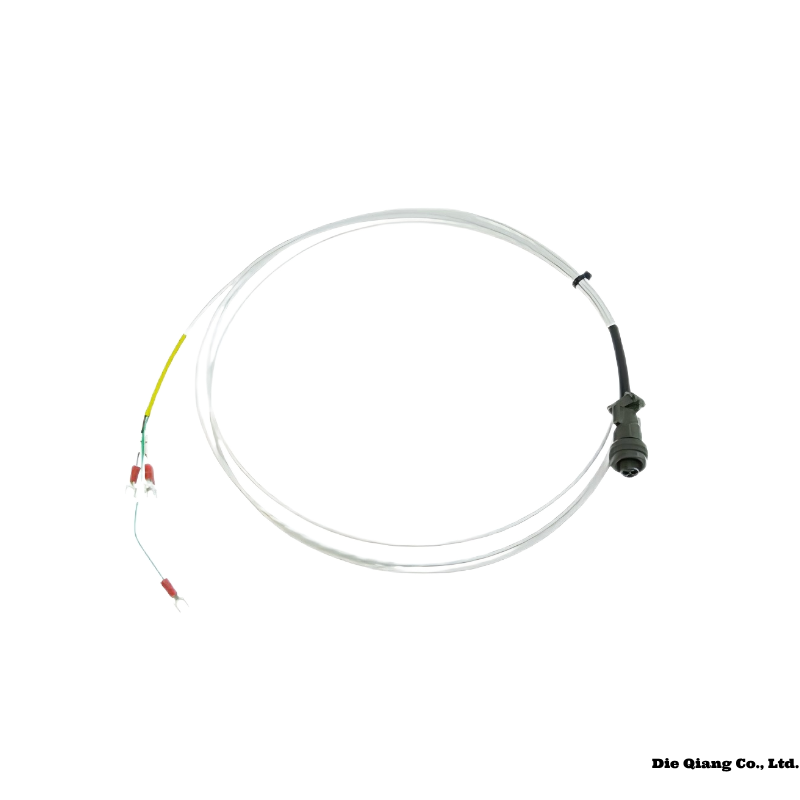

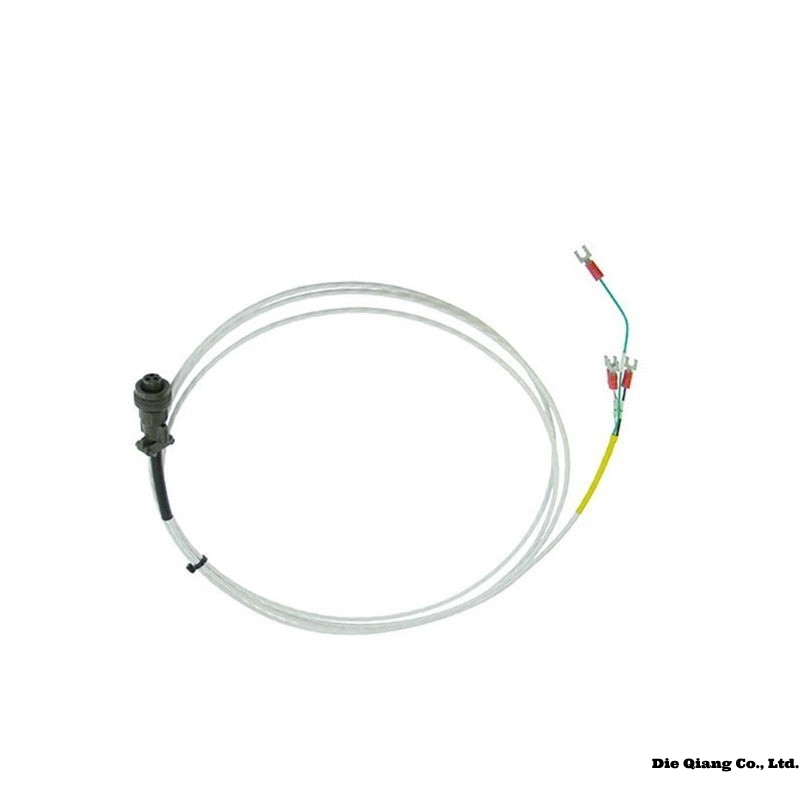

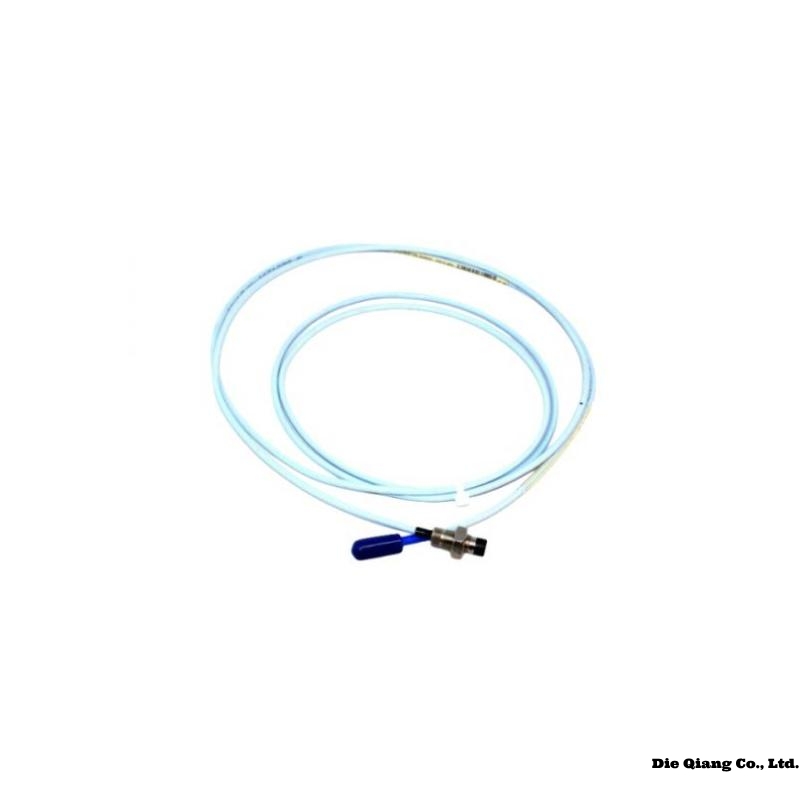

Bently Nevada 16710-12 Product Overview

The Bently Nevada 16710-12 is a high-performance vibration monitoring module designed for industrial machinery protection and condition monitoring. It is part of the 3500 Series of monitoring systems by Bently Nevada, a leading brand in predictive maintenance and asset protection.

This module is widely used in critical applications such as power generation, oil & gas, and heavy industrial machinery to detect abnormal vibrations, prevent equipment failure, and optimize operational efficiency.

Product Advantages

- High Accuracy & Reliability – Provides precise vibration measurements with minimal signal distortion.

- Robust Construction – Built to withstand harsh industrial environments (high temperatures, dust, and moisture).

- Easy Integration – Compatible with Bently Nevada’s 3500 Series monitoring systems for seamless data collection and analysis.

- Advanced Diagnostics – Supports real-time monitoring and fault detection to minimize downtime.

- Long Service Life – Engineered for durability with high-quality components.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 16710-12 |

| Input Voltage | 18 – 30 VDC |

| Power Consumption | 5W (typical) |

| Operating Temp. | -30°C to +70°C |

| Cable length | 12 foot |

| Weight | 2 kg |

| Frequency Range | 10 Hz – 10 kHz |

| Output Signal | 4-20 mA, RS-485 |

| Enclosure Rating | IP66 |

| Certifications | ATEX, IECEx |

Applications

The Bently Nevada 16710-12 is used in:

- Gas & Steam Turbines – Monitors blade vibrations and bearing health.

- Compressors & Pumps – Detects imbalance, misalignment, and cavitation.

- Electric Motors & Generators – Prevents bearing failures and rotor issues.

- Refineries & Petrochemical Plants – Ensures safe operation of rotating machinery.

Compatible Models

The 16710-12 works with:

- 3500/22M (Transient Data Interface)

- 3500/25 (Keyphasor Module)

- 3500/32M (16-Channel Relay Module)

- 3500/40M (Proximitor Power Supply)

- 3500/42M (TMR Analog Monitor)

- 3500/50 (Rack Interface Module)

Installation Instructions

- Mounting – Secure the module in a 3500 Series rack using the provided slots.

- Wiring – Connect input power (18-30VDC) and sensor signals as per the wiring diagram.

- Configuration – Use System 1™ software to set alarm thresholds and monitoring parameters.

- Testing – Verify signal integrity and calibration before full operation.

- Maintenance – Regularly inspect connections and clean dust/debris.

Recommended Similar Models (6 Alternatives)

| Model | Description | Voltage | Dimensions | Weight | Key Feature |

|---|---|---|---|---|---|

| 16710-10 | Vibration Monitor (8-Channel) | 18-30VDC | 200x100x50mm | 0.5kg | Lower channel count |

| 16710-15 | High-Temp Vibration Monitor | 24VDC | 200x100x50mm | 0.6kg | For extreme heat |

| 16720-12 | Dual-Channel Vibration Monitor | 18-30VDC | 220x110x60mm | 0.7kg | Redundant inputs |

| 16745-01 | Wireless Vibration Module | 12-24VDC | 150x80x40mm | 0.3kg | IoT-enabled |

| 16750-05 | Explosion-Proof Vibration Monitor | 24VDC | 210x105x55mm | 0.8kg | ATEX Zone 1 |

| 16760-08 | High-Frequency Vibration Analyzer | 18-30VDC | 200x100x50mm | 0.5kg | Up to 20kHz range |

Top 8 Popular Bently Nevada Models (With Parameters)

| Model | Type | Voltage | Dimensions | Weight | Key Feature |

|---|---|---|---|---|---|

| 3500/22M | Transient Data Interface | 24VDC | 200x100x50mm | 0.5kg | High-speed data capture |

| 3500/25 | Keyphasor Module | 18-30VDC | 200x100x50mm | 0.5kg | RPM synchronization |

| 3500/32M | Relay Module (16-Ch) | 24VDC | 200x100x50mm | 0.6kg | Safety shutdowns |

| 3500/40M | Proximitor Power Supply | 24VDC | 200x100x50mm | 0.5kg | Sensor excitation |

| 3500/42M | TMR Analog Monitor | 24VDC | 200x100x50mm | 0.7kg | Triple modular redundancy |

| 3500/50 | Rack Interface Module | 24VDC | 200x100x50mm | 0.5kg | System communication |

| 3300/16 | Proximity Transducer | -18 to -24VDC | 80x40x25mm | 0.2kg | Shaft displacement |

| 3300/25 | Velocity Seismic Sensor | 12-24VDC | 100x60x40mm | 0.4kg | Low-frequency vibration |

FAQ (Frequently Asked Questions)

Q1: What is the operating voltage range of the 16710-12?

A1: The module operates on 18-30VDC.

Q2: Can the 16710-12 be used in hazardous areas?

A2: Yes, it is ATEX/IECEx certified for explosive environments.

Q3: What software is needed to configure this module?

A3: Use Bently Nevada’s System 1™ for setup and diagnostics.

Q4: What is the frequency response range?

A4: It covers 10Hz to 10kHz, suitable for most industrial machinery.

Q5: Is the 16710-12 compatible with third-party sensors?

A5: It works best with Bently Nevada sensors but can interface with others if properly calibrated.

Q6: How often should maintenance be performed?

A6: Inspect annually or per operational conditions (dust, temperature extremes).

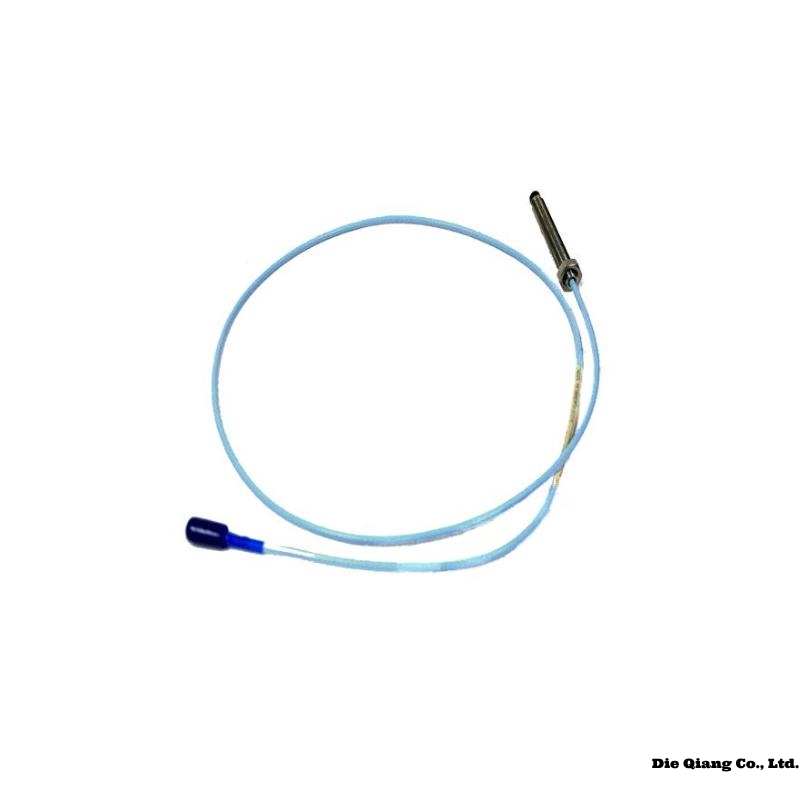

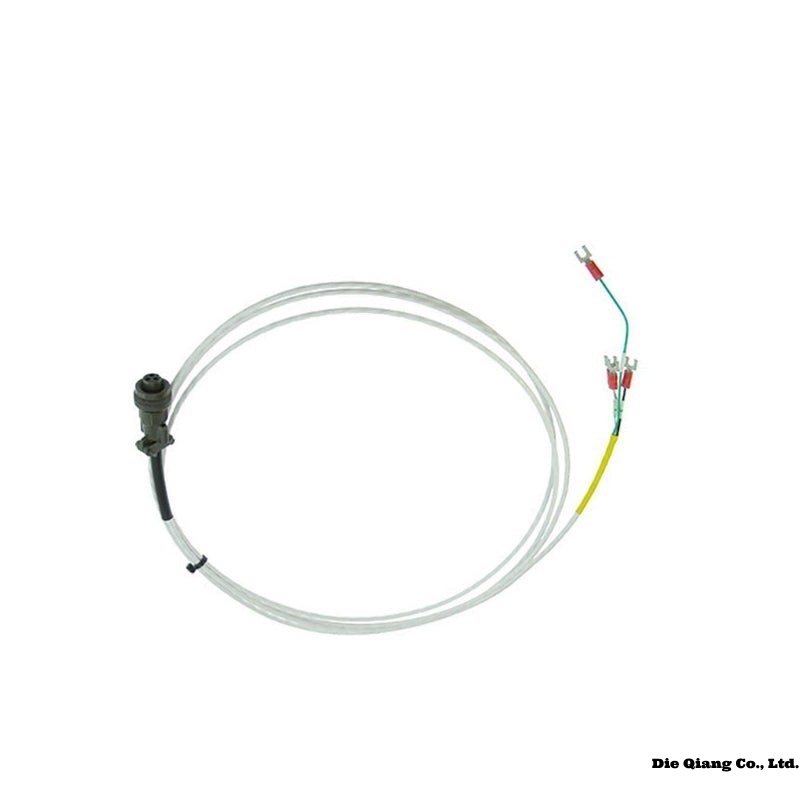

Bently Nevada 16710-12 16710 Interconnect Cable

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||