| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

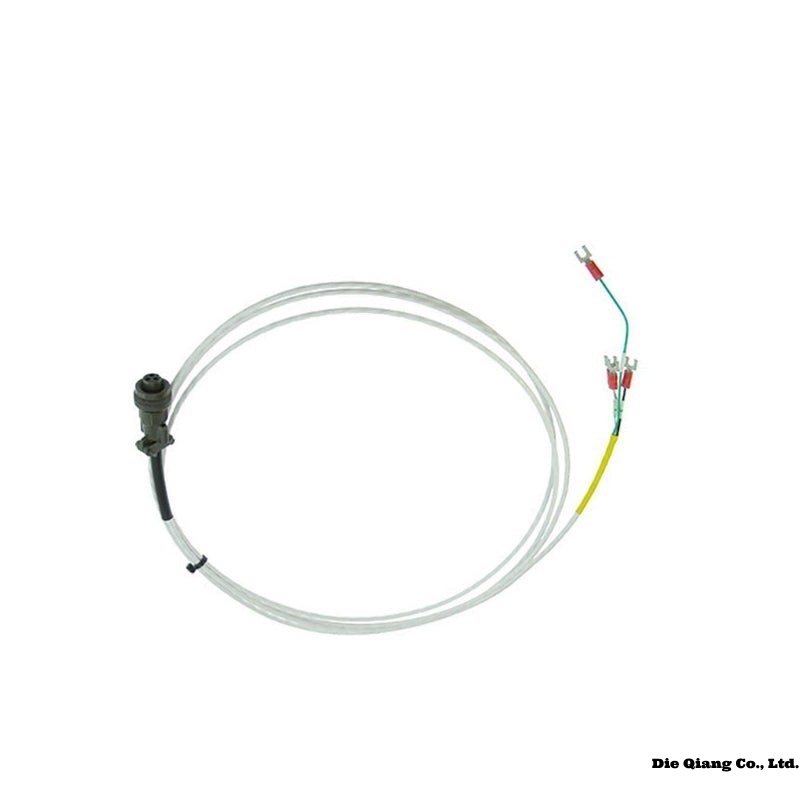

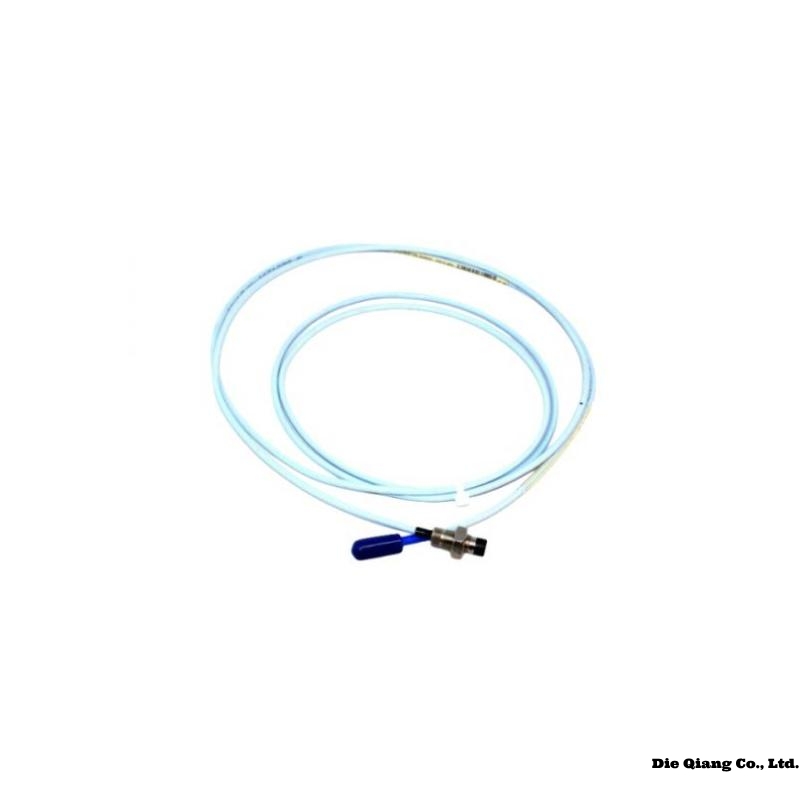

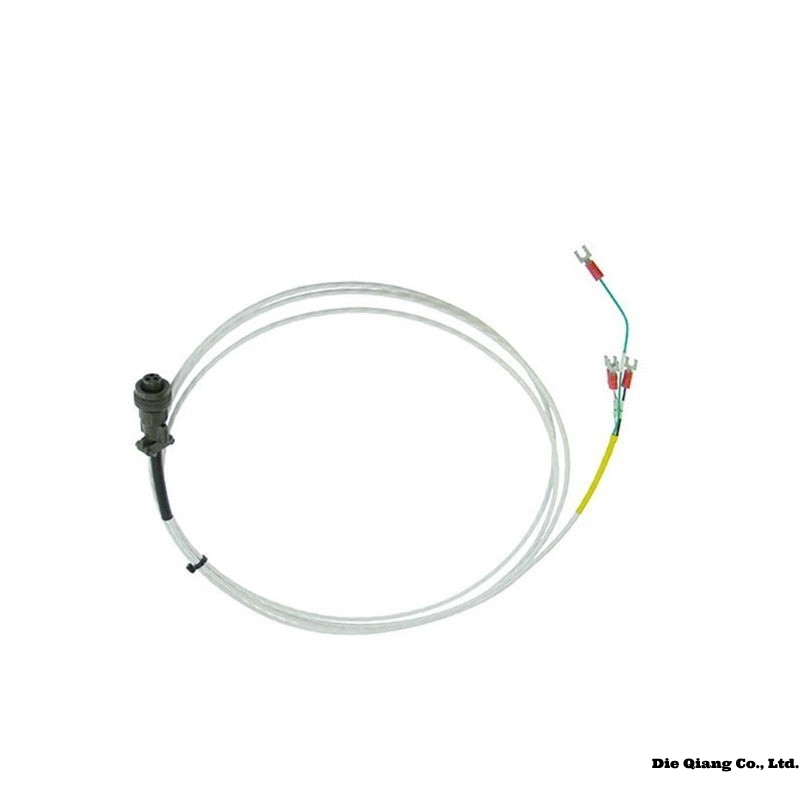

Product Introduction: Bently Nevada 16710-15

The Bently Nevada 16710-15 is a highly reliable and high-performance extension cable designed to support Bently Nevada’s proximity transducer systems, specifically engineered for industrial vibration monitoring and condition monitoring systems. This model plays a crucial role in transmitting signals between the proximity probe and the monitoring system, ensuring accurate and uninterrupted data flow in demanding industrial environments. With robust design features and consistent transmission capabilities, the 16710-15 is widely trusted across industries for its stable and long-term performance.

It is part of the Bently Nevada 3300 XL series, known for high precision, compatibility with a broad range of sensors, and excellent resistance to harsh conditions including heat, moisture, oil, and vibration. The 16710-15 extension cable offers dependable performance in power plants, refineries, offshore platforms, and other critical infrastructure.

Product Advantages

-

High Signal Integrity: Maintains accurate signal transmission with minimal loss or interference, even in electrically noisy environments.

-

Industrial Grade Durability: Constructed with rugged, environmentally resistant materials suitable for extreme industrial applications.

-

Plug-and-Play Compatibility: Designed to integrate seamlessly with 3300 XL proximity transducer systems and compatible Bently Nevada monitoring modules.

-

Extended Range Flexibility: The 15-foot (4.57 meters) length allows installation in large machinery or remote locations where proximity probes are distanced from monitors.

-

Minimized Downtime: Ensures continuous and reliable data transfer, reducing risks of unexpected machine shutdowns.

-

Easy Maintenance and Replacement: Standardized connector types simplify replacement procedures without requiring additional calibration.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 16710-15 |

| Product Type | Extension Cable |

| Compatible Series | Bently Nevada 3300 XL Series |

| Cable Type | Coaxial, shielded |

| Connector Type | ClickLoc connectors on both ends |

| Voltage Rating | 300 V RMS maximum |

| Operating Temperature | -51°C to +177°C (-60°F to +350°F) |

| Insulation Resistance | >10 GΩ at 500 VDC |

| Shielding | Braided shielding for noise immunity |

| Outer Jacket Material | FEP (Fluorinated Ethylene Propylene) |

| Weight | 2 kg |

| Cable length | 15 foot |

| RoHS Compliance | Yes |

Product Applications

The Bently Nevada 16710-15 is widely applied in industrial settings where vibration and condition monitoring are essential to equipment health. Common applications include:

-

Gas and steam turbines

-

Centrifugal compressors

-

Industrial pumps

-

Electric motors and generators

-

Gearboxes and fans

-

Power generation plants

-

Petrochemical refineries

-

Offshore oil & gas platforms

Compatible Models

The 16710-15 extension cable is typically used in conjunction with the following components:

-

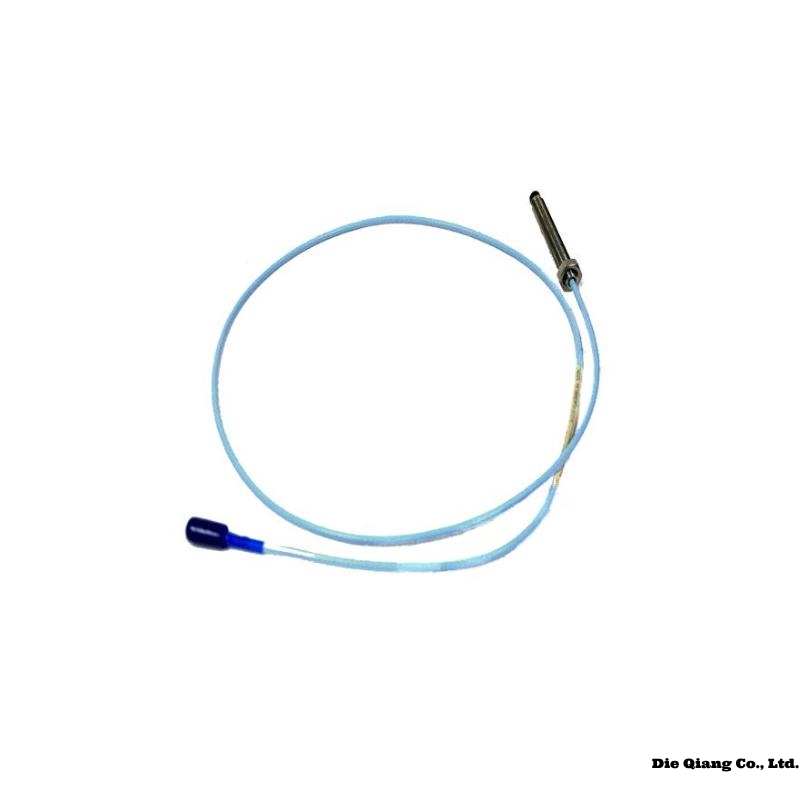

3300 XL Proximity Probes (e.g., 330101, 330103, 330104)

-

3300 XL Extension Cable Series (complementary lengths available)

-

3300 XL Proximitor Sensor (e.g., 3300 XL 3300 25mm, 3300 XL NSv)

-

Monitoring Systems (e.g., Bently Nevada 3500 Series)

-

Proximity Transducer Systems with 5 mm or 8 mm tip diameters

Installation Instructions

-

Inspection Before Installation

Ensure the cable is free of visible damage. Inspect the connectors and insulation before proceeding. -

Routing the Cable

Carefully route the cable from the proximity probe to the monitoring system. Avoid placing the cable near high voltage lines or sources of electromagnetic interference. -

Connection

-

Connect one end of the 16710-15 cable to the proximitor sensor.

-

Connect the other end to the extension input of the monitoring module using ClickLoc connectors.

-

Ensure connectors are properly tightened and secured to avoid disconnection or signal loss.

-

-

Securing the Cable

Use cable ties or clamps to secure the cable to stable surfaces, avoiding tight bends or sharp angles which may affect cable integrity. -

Testing the Installation

Perform a system check to ensure proper signal transmission. Check impedance and continuity with appropriate diagnostic tools. -

Maintenance

Periodically inspect the cable for wear, corrosion, or loosened connectors, especially in high-vibration or high-temperature zones.

6 Related Models from the Same Series

| Model | Description | Length | Connector Type | Voltage Rating | Weight |

|---|---|---|---|---|---|

| 16710-05 | Extension Cable, 5 ft | 5 ft (1.52m) | ClickLoc | 300 V RMS | 0.20 kg |

| 16710-10 | Extension Cable, 10 ft | 10 ft (3.05m) | ClickLoc | 300 V RMS | 0.35 kg |

| 16710-25 | Extension Cable, 25 ft | 25 ft (7.62m) | ClickLoc | 300 V RMS | 0.55 kg |

| 16710-30 | Extension Cable, 30 ft | 30 ft (9.14m) | ClickLoc | 300 V RMS | 0.60 kg |

| 330130-040-00-00 | Extension Cable, 4m | 4 m | Standard Connectors | 300 V RMS | 0.30 kg |

| 330130-080-00-00 | Extension Cable, 8m | 8 m | Standard Connectors | 300 V RMS | 0.40 kg |

8 Popular Bently Nevada Models

| Model | Description | Function | Voltage | Dimensions (L×W×H) | Weight |

|---|---|---|---|---|---|

| 330104-00-05-10-02-00 | 3300 XL 8mm Proximity Probe | Vibration Measurement | 24 VDC | 90mm × 8mm × 8mm | 0.15 kg |

| 330103-00-06-10-02-00 | 3300 XL 5mm Proximity Probe | Displacement Monitoring | 24 VDC | 80mm × 5mm × 5mm | 0.12 kg |

| 330130-080-00-00 | 3300 XL Extension Cable, 8m | Signal Transmission Cable | 300 V RMS | 8 m length × 5.2 mm dia | 0.40 kg |

| 330180-91-05 | Proximitor Sensor for 3300 XL Series | Sensor Signal Conditioning | 24 VDC | 120mm × 60mm × 35mm | 0.30 kg |

| 3500/42M | Dynamic Pressure Monitor Module | Machinery Monitoring | 24 VDC | 150mm × 100mm × 30mm | 0.45 kg |

| 3500/22M | Transient Data Interface (TDI) | System Interface Module | 24 VDC | 140mm × 100mm × 25mm | 0.40 kg |

| 3500/15 | Power Supply Module | Provides Power to Racks | 120/240 VAC | 130mm × 100mm × 40mm | 0.60 kg |

| 330106-05-30-10-02-00 | Proximity Probe with Cable and Sensor | Complete Vibration System | 24 VDC | 5 m cable; probe: 90mm long | 0.50 kg |

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the 16710-15 extension cable?

A1: It connects the proximity probe to the proximitor sensor or monitoring module, enabling accurate signal transmission over extended distances.

<br>

Q2: Is the 16710-15 compatible with older Bently Nevada systems?

A2: Yes, it is backward compatible with many legacy Bently Nevada proximity transducer systems that use standard ClickLoc connectors.

<br>

Q3: Can the 16710-15 be used in high-temperature areas?

A3: Yes, the cable operates reliably in temperatures ranging from -51°C to +177°C, making it suitable for high-temperature industrial applications.

<br>

Q4: Does the cable require calibration after installation?

A4: No, calibration is typically not required unless the connected probe or sensor is replaced or recalibrated.

<br>

Q5: What should I do if I experience signal noise in the system?

A5: Ensure the cable is properly shielded and not routed near sources of EMI. Inspect the connectors and cable jacket for damage or wear.

<br>

Q6: How often should the 16710-15 cable be inspected or replaced?

A6: Visual inspections should be done during routine maintenance intervals, especially in high-vibration areas. Replacement is recommended if there is physical damage or degradation in signal quality.

<br>

Bently Nevada 16710-15 16710 Interconnect Cable

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||