| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

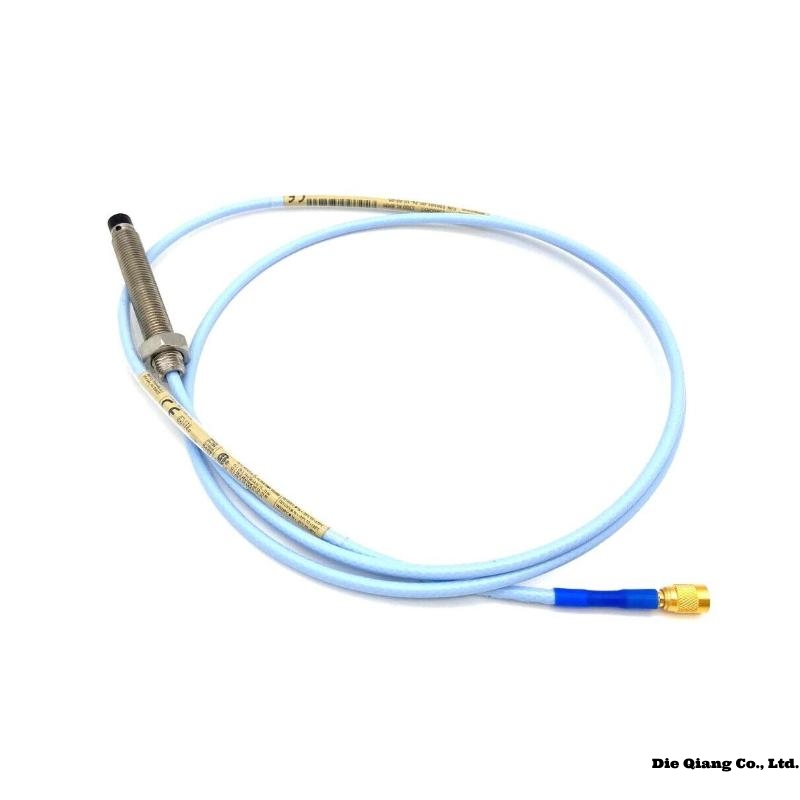

Bently Nevada 170180-01-05 Product Overview

The Bently Nevada 170180-01-05 is a high-quality vibration monitoring sensor designed for industrial applications. It is part of the Bently Nevada product line, renowned for its precision and reliability in monitoring rotating machinery. The 170180-01-05 provides real-time monitoring of critical machine components such as bearings, shafts, and motors. It is engineered to offer consistent performance, helping to detect early signs of mechanical failure, thereby enhancing machine longevity and reducing downtime in industrial environments.

This product utilizes advanced technology to measure vibration levels and convert them into digital signals that can be easily analyzed. It is designed to be used in various industries including oil and gas, power generation, and manufacturing, where precise vibration analysis is essential for maintaining equipment efficiency and reliability.

Advantages of Bently Nevada 170180-01-05

-

High Accuracy: The sensor provides highly accurate vibration measurements, enabling early detection of potential faults.

-

Durability: Built to withstand harsh industrial conditions, including high temperatures, moisture, and electrical noise.

-

Real-Time Monitoring: Offers continuous monitoring, ensuring that potential problems are identified as soon as they arise.

-

Ease of Integration: It can be easily integrated with other monitoring systems, ensuring smooth operation and consistent data collection.

-

Reduced Maintenance Costs: By detecting issues early, it helps prevent catastrophic failures, thereby reducing costly repairs and downtime.

-

Compliance: Meets industry standards for vibration monitoring, making it suitable for use in regulated environments.

Technical Specifications

| Parameter | Value |

|---|---|

| Dimensions | 105.3 x 126.9 x 21.6 mm |

| Weight | 0.277 kg |

| Voltage | 24V DC |

| Temperature Range | -20°C to +85°C |

| Output Type | Analog / Digital |

| Frequency Response | 10 Hz to 5 kHz |

| Measurement Range | 0.1 g to 10 g |

| Power Consumption | 10W |

Applications of Bently Nevada 170180-01-05

The Bently Nevada 170180-01-05 sensor is widely used in industries where machinery condition monitoring is critical to operations. Its applications include:

-

Rotating Equipment Monitoring: Used in monitoring pumps, motors, turbines, compressors, and fans.

-

Power Generation: Ensures reliability and performance of critical equipment in power plants.

-

Oil & Gas Industry: Vital for monitoring machinery used in exploration, production, and processing facilities.

-

Manufacturing: Helps in the maintenance of production lines and machinery used in manufacturing processes.

-

Mining: Detects early signs of failure in machinery used in the mining sector.

Compatible Models for Use with Bently Nevada 170180-01-05

| Model Number | Description |

|---|---|

| 170180-01-10 | Vibration sensor for low-speed machinery |

| 170180-01-12 | Vibration sensor with extended frequency range |

| 170180-01-06 | Sensor designed for high-temperature environments |

| 170180-01-08 | General-purpose vibration sensor for industrial use |

| 170180-01-07 | Vibration sensor with additional output options |

| 170180-01-11 | Vibration sensor for critical machinery applications |

Installation Instructions for Bently Nevada 170180-01-05

-

Positioning: Mount the sensor as close as possible to the monitored machinery to ensure optimal performance. Ensure that the sensor is aligned correctly with the vibration axis of the machinery.

-

Wiring: Connect the sensor’s electrical connections to the monitoring system according to the provided wiring diagram. Ensure proper insulation and grounding to avoid electrical interference.

-

Calibration: Perform calibration after installation to verify that the sensor is functioning correctly and providing accurate data.

-

Testing: After installation, run tests to ensure the system is reading the correct vibration levels and is integrated correctly with other monitoring devices.

-

Maintenance: Regularly check the sensor for signs of wear or damage. Replace components as necessary to maintain optimal performance.

FAQ for Bently Nevada 170180-01-05

Q1: What is the primary function of the Bently Nevada 170180-01-05?

A1: The Bently Nevada 170180-01-05 is designed to monitor the vibration levels of rotating machinery, helping detect early signs of failure to prevent catastrophic breakdowns.

Q2: Can the Bently Nevada 170180-01-05 be used in high-temperature environments?

A2: Yes, it can operate in temperatures ranging from -20°C to +85°C, making it suitable for most industrial applications.

Q3: How does the vibration sensor work?

A3: The sensor measures the vibration levels of the machinery and converts the data into electrical signals that can be monitored and analyzed for potential issues.

Q4: Is the Bently Nevada 170180-01-05 compatible with other monitoring systems?

A4: Yes, it is designed to integrate seamlessly with various monitoring systems, allowing for easy data analysis and fault detection.

Q5: What industries use the Bently Nevada 170180-01-05?

A5: It is widely used in industries such as oil and gas, power generation, manufacturing, mining, and more for machinery condition monitoring.

Q6: How often does the sensor need to be maintained?

A6: The sensor should be inspected periodically for signs of wear and tear. Regular calibration is also recommended to ensure accurate readings.

Recommended Bently Nevada Products

Here are 8 other popular models from Bently Nevada that are frequently used in industrial machinery monitoring:

| Model Number | Description | Key Parameters |

|---|---|---|

| 330500-00 | Vibration Monitoring System | Voltage: 24V DC, Measurement Range: 0.1g – 10g |

| 3500/42M | Monitoring for Critical Machinery | Frequency: 1Hz to 5 kHz, Power: 15W |

| 3300 XL | Proximity and Vibration Transducer | Measurement Range: 0.1mm – 2mm, Power: 24V DC |

| 3500/20 | Dynamic Data Monitoring | Temperature Range: -20°C to +60°C, Output: Analog/Digital |

| 3300 | Vibration Sensor for Industrial Equipment | Frequency: 0.1 Hz to 5 kHz, Power: 12V DC |

| 3500/33 | Machinery Protection System | Measurement Range: 0.1g – 10g, Voltage: 24V DC |

| 3701 | Machinery Diagnostic System | Temperature: -20°C to +85°C, Power: 24V DC |

| 3300 XT | Vibration Sensor for Hazardous Areas | Voltage: 24V DC, Frequency: 10 Hz to 5 kHz |

Bently Nevada 170180-01-05 TRANSDUCER I/O MODULE

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||