| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

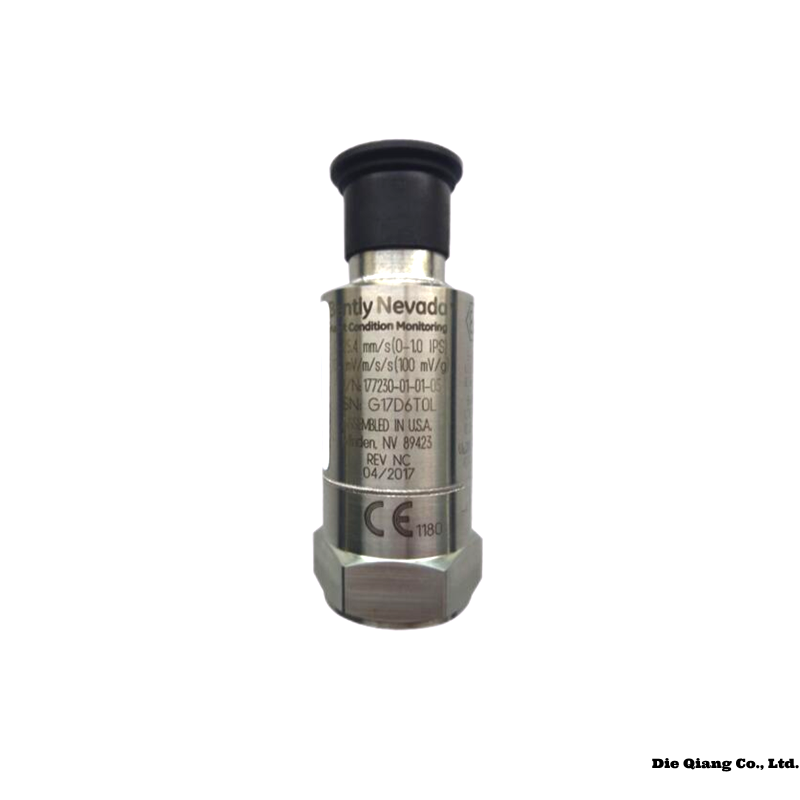

Bently Nevada 177230-01-02-05 Product Overview

The Bently Nevada 177230-01-02-05 is a high-performance vibration monitoring module designed for industrial machinery protection and condition monitoring. It is part of the Bently Nevada 3500 Series, a widely recognized system for machinery health management. This module provides reliable vibration measurement and analysis, ensuring optimal operational safety and efficiency for rotating equipment.

Product Advantages

- High Accuracy – Delivers precise vibration measurements for early fault detection.

- Robust Design – Built to withstand harsh industrial environments (e.g., high temperatures, EMI interference).

- Compatibility – Integrates seamlessly with the Bently Nevada 3500 Series monitoring system.

- Easy Configuration – User-friendly setup and diagnostics via the 3500 Series framework.

- Long-Term Reliability – Proven performance in critical applications such as turbines, compressors, and pumps.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 177230-01-02-05 |

| Dimensions (diameter) | 25.4 mm |

| Weight | 0.131 kg |

| Operating Voltage | 18 – 30 VDC |

| Input Signals | Accepts dynamic vibration signals (e.g., from proximity probes or accelerometers) |

| Frequency Range | 10 Hz – 10 kHz |

| Output Signals | 4-20 mA, relay alarms |

| Operating Temp. | -40°C to +85°C (-40°F to +185°F) |

| Certifications | ATEX, IECEx, UL, CE compliant |

Applications

The 177230-01-02-05 is widely used in:

- Gas & Steam Turbines – Monitors blade passing frequencies and rotor imbalances.

- Compressors & Pumps – Detects bearing wear and misalignment.

- Power Generation – Ensures safe operation of generators and auxiliary equipment.

- Oil & Gas – Protects critical machinery in refineries and pipelines.

Compatible Models (Recommended Pairings)

For a complete monitoring system, consider pairing with:

- 3300 XL 8mm Proximity Probes – For shaft vibration measurement.

- 3500/22M Transient Data Interface – Captures high-speed transient events.

- 3500/92 Communication Gateway – Enables remote monitoring via Ethernet.

- 3500/15 Power Supply Module – Provides stable power to the rack.

Recommended Similar/Related Models

Here are 6 alternative models from the same series:

| Model Number | Description | Voltage | Dimensions | Weight |

|---|---|---|---|---|

| 177230-01-02-10 | Enhanced vibration monitor with wider frequency range | 18-30 VDC | 8.5 x 3.5 x 1.2 in | 1.5 lbs |

| 177229-01-01-05 | Dual-channel vibration monitor | 24 VDC | 8.5 x 3.5 x 1.2 in | 1.6 lbs |

| 177231-01-03-00 | High-temperature variant (up to 100°C) | 18-30 VDC | 8.5 x 3.5 x 1.2 in | 1.5 lbs |

| 177235-01-01-05 | Low-power version for remote installations | 12-24 VDC | 8.5 x 3.5 x 1.2 in | 1.4 lbs |

| 177240-01-02-05 | Multi-parameter monitor (vibration + temperature) | 24 VDC | 8.5 x 3.5 x 1.2 in | 1.7 lbs |

| 177250-01-01-00 | Explosion-proof certified model (ATEX Zone 1) | 18-30 VDC | 8.5 x 3.5 x 1.2 in | 1.8 lbs |

Top 8 Popular Bently Nevada Models

| Model Number | Type | Voltage | Dimensions | Weight | Key Feature |

|---|---|---|---|---|---|

| 3500/42M | Proximitor Monitor | 24 VDC | 8.5 x 3.5 x 1.2 in | 1.5 lbs | Eddy-current gap measurement |

| 3500/22M | Transient Data Module | 18-30 VDC | 8.5 x 3.5 x 1.2 in | 1.6 lbs | High-speed data capture |

| 3300 XL 8mm | Proximity Probe | N/A | 8mm diameter | 0.2 lbs | Shaft vibration sensing |

| 3500/92 | Communication Gateway | 24 VDC | 8.5 x 3.5 x 1.2 in | 1.7 lbs | Ethernet connectivity |

| 3500/15 | Power Supply Module | 120/240 VAC | 8.5 x 3.5 x 1.2 in | 2.0 lbs | Rack power distribution |

| 1900/65A | Accelerometer | 18-30 VDC | 1.5 x 1.5 x 1 in | 0.3 lbs | High-frequency vibration |

| 3500/32 | Relay Module | 24 VDC | 8.5 x 3.5 x 1.2 in | 1.5 lbs | Alarm relay outputs |

| 3701/46-01-00 | Speed Monitor | 18-30 VDC | 8.5 x 3.5 x 1.2 in | 1.6 lbs | RPM measurement |

Installation Instructions

- Mounting – Install the module in a 3500 Series rack using the provided slots. Ensure proper grounding.

- Wiring – Connect input signals from vibration sensors (e.g., proximity probes) to the designated terminals.

- Power-Up – Apply 18-30 VDC power and verify LED status indicators.

- Configuration – Use the 3500 Rack Configuration Software to set alarm thresholds and signal parameters.

- Testing – Validate readings using a known vibration source or simulator.

FAQ (Frequently Asked Questions)

Q1: What is the operating temperature range of the 177230-01-02-05?

A1: It operates from -40°C to +85°C (-40°F to +185°F).

Q2: Can this module be used in hazardous areas?

A2: Yes, it is ATEX and IECEx certified for hazardous environments.

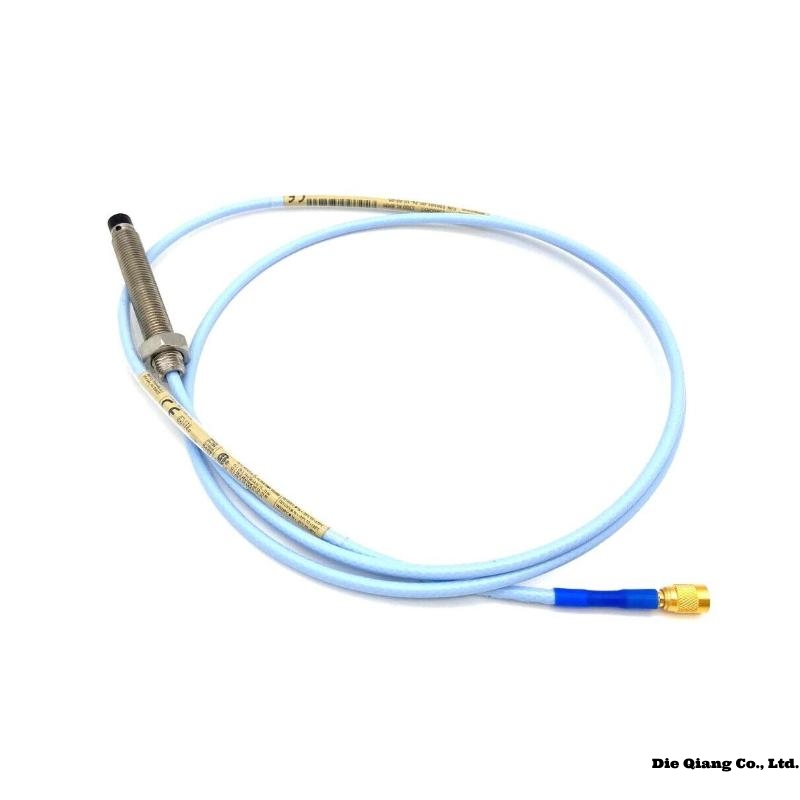

Q3: What type of sensors are compatible with this module?

A3: It works with proximity probes (e.g., 3300 XL series) and accelerometers.

Q4: How do I troubleshoot a faulty module?

A4: Check LED status lights and use the 3500 software for diagnostics. Replace if LEDs indicate failure.

Q5: Is calibration required?

A5: Factory calibration is standard, but periodic verification is recommended.

Q6: Can this module communicate with PLCs?

A6: Yes, via the 3500/92 Communication Gateway for integration with control systems.

Bently Nevada 177230-01-02-05 Seismic Transmitter

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||