| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

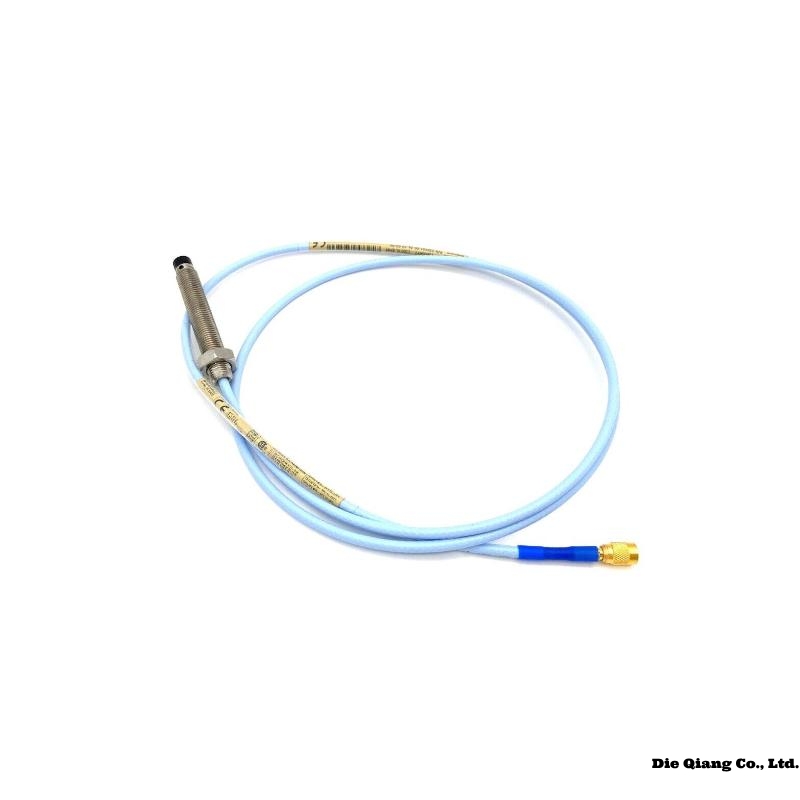

The Bently Nevada 190501-04-00-00 is a high-precision vibration sensor designed for industrial control systems, particularly for monitoring and diagnostics of rotating machinery. It is engineered to offer reliable performance in harsh industrial environments, ensuring accurate real-time vibration data for equipment health monitoring. The product is part of the Bently Nevada portfolio, known for its high-quality monitoring equipment used in various industries such as oil & gas, power generation, and manufacturing.

Advantages

-

High Precision: The sensor offers highly accurate vibration measurements, ensuring reliable machinery monitoring.

-

Durability: Built with industrial-grade materials, it is resistant to extreme environmental conditions, such as temperature fluctuations, moisture, and mechanical stress.

-

Easy Integration: Designed to integrate smoothly with existing Bently Nevada monitoring systems for a seamless experience.

-

Real-Time Data: Provides immediate vibration data that can be analyzed for preventive maintenance and fault detection.

-

Low Maintenance: With robust construction and design, the sensor requires minimal maintenance, reducing downtime and operational costs.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 190501-04-00-00 |

| Type | Vibration Sensor |

| Vibration Range | 0-100 mm/s |

| Operating Temperature | -40°C to 85°C |

| Supply Voltage | 24 VDC ± 10% |

| Output Type | 4-20 mA (Analog Output) |

| Housing Material | Stainless Steel |

| Dimensions(diameter) | 33 mm |

| Weight | 0.297 kg |

| Mounting Type | Direct threaded mounting |

| Environmental Protection | IP67 (dustproof, waterproof) |

| Signal Processing | Continuous vibration monitoring with integrated signal conditioning |

Applications

The Bently Nevada 190501-04-00-00 sensor is used in various industrial applications, primarily focused on machinery and equipment monitoring. Key applications include:

-

Rotating machinery health monitoring: Used to measure vibrations in motors, turbines, pumps, and compressors.

-

Predictive maintenance: Enables proactive maintenance scheduling based on vibration analysis, preventing unexpected downtime.

-

Condition-based monitoring systems: Integration with larger monitoring systems for real-time condition monitoring and diagnostics of industrial equipment.

-

Energy and utilities industries: Power plants and other utility industries rely on vibration data for optimizing equipment performance and ensuring operational safety.

Compatible Models

-

190501-04-00-00 (Base Model)

-

190501-04-01-00-00 (Enhanced version with additional features)

-

190501-04-00-01 (For high-temperature environments)

-

190501-04-00-02 (Vibration sensor with wireless integration)

-

190501-04-00-03 (Version with added accelerometer for higher sensitivity)

-

190501-04-00-04 (For hazardous environments with explosion-proof casing)

Installation Instructions

-

Mounting Location: Choose a location where vibration measurement is crucial, such as near bearings or motor shafts.

-

Mounting Process: Use the threaded mounting feature to secure the sensor directly onto the machine surface. Ensure proper alignment with the axis of rotation for accurate measurements.

-

Wiring: Connect the sensor’s output to the system input. Ensure the proper voltage supply of 24 VDC ± 10%.

-

Environmental Protection: Ensure the sensor is installed in environments that comply with its IP67 rating for dust and water resistance.

-

Calibration: After installation, calibrate the sensor with a vibration analyzer to ensure accurate readings.

Related Model Recommendations (Same Series or Similar Models)

| Model | Vibration Range | Voltage | Output Type | Dimensions | Weight |

|---|---|---|---|---|---|

| 190501-04-01-00-00 | 0-100 mm/s | 24 VDC ± 10% | 4-20 mA | 130mm x 80mm x 50mm | 0.92 kg |

| 190501-04-00-01 | 0-150 mm/s | 24 VDC ± 10% | 4-20 mA | 140mm x 85mm x 55mm | 1.05 kg |

| 190501-04-00-02 | 0-100 mm/s | 24 VDC ± 10% | Wireless (IoT) | 125mm x 80mm x 45mm | 0.88 kg |

| 190501-04-00-03 | 0-100 mm/s | 24 VDC ± 10% | 4-20 mA | 120mm x 75mm x 40mm | 0.87 kg |

| 190501-04-00-04 | 0-200 mm/s | 24 VDC ± 10% | 4-20 mA | 135mm x 90mm x 50mm | 1.10 kg |

| 190501-04-00-05 | 0-120 mm/s | 24 VDC ± 10% | 4-20 mA | 125mm x 80mm x 50mm | 0.95 kg |

Popular Bently Nevada Models

| Model | Vibration Range | Voltage | Output Type | Dimensions | Weight |

|---|---|---|---|---|---|

| 330500-00-00 | 0-100 mm/s | 24 VDC ± 10% | 4-20 mA | 120mm x 70mm x 40mm | 0.80 kg |

| 350100-00-00 | 0-150 mm/s | 24 VDC ± 10% | 4-20 mA | 150mm x 80mm x 50mm | 1.10 kg |

| 330500-02-00 | 0-50 mm/s | 24 VDC ± 10% | 4-20 mA | 125mm x 65mm x 45mm | 0.70 kg |

| 350100-01-00 | 0-200 mm/s | 24 VDC ± 10% | 4-20 mA | 130mm x 75mm x 55mm | 1.20 kg |

| 330180-00-00 | 0-50 mm/s | 24 VDC ± 10% | 4-20 mA | 110mm x 60mm x 40mm | 0.75 kg |

| 350800-00-00 | 0-100 mm/s | 24 VDC ± 10% | 4-20 mA | 135mm x 80mm x 50mm | 0.95 kg |

| 330830-00-00 | 0-120 mm/s | 24 VDC ± 10% | 4-20 mA | 125mm x 70mm x 45mm | 0.90 kg |

| 350300-00-00 | 0-80 mm/s | 24 VDC ± 10% | 4-20 mA | 120mm x 75mm x 45mm | 0.85 kg |

FAQ

Q1: What is the maximum vibration range of the Bently Nevada 190501-04-00-00 sensor?

A1: The maximum vibration range is 100 mm/s, making it suitable for a wide range of industrial machinery applications.

Q2: What is the required operating temperature for the Bently Nevada 190501-04-00-00?

A2: The sensor operates effectively within a temperature range of -40°C to 85°C, ensuring reliable performance in both hot and cold environments.

Q3: How does the Bently Nevada 190501-04-00-00 connect to the monitoring system?

A3: The sensor uses a 4-20 mA analog output signal, which can be easily integrated into most industrial monitoring systems.

Q4: Can the Bently Nevada 190501-04-00-00 be used in hazardous locations?

A4: While this specific model is not designed for hazardous areas, Bently Nevada offers other models with explosion-proof enclosures suitable for such environments.

Q5: What is the warranty period for the Bently Nevada 190501-04-00-00 sensor?

A5: The warranty period is typically one year from the date of purchase, ensuring product quality and reliability.

Q6: How is the sensor mounted onto the machine?

A6: The sensor is equipped with a threaded mounting feature, which allows for direct and secure attachment to the machine surface. Proper alignment with the axis of rotation is essential for accurate readings.

Bently Nevada 190501-04-00-00 CT Velocity Transducer

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||