| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

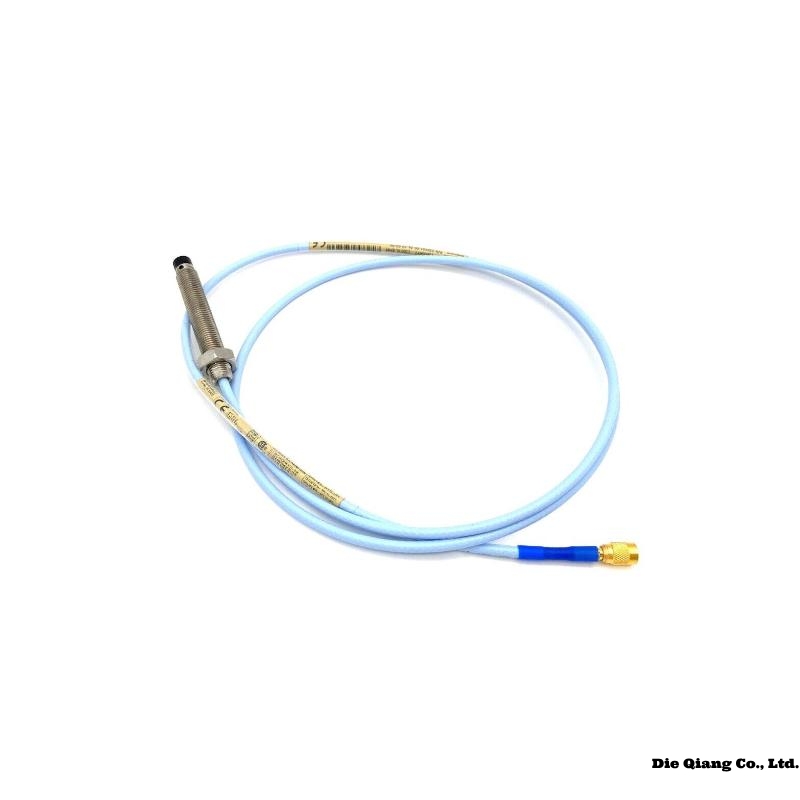

The Bently Nevada 190501-12-00-04 is a high-performance vibration monitoring system designed for use in industrial machinery applications, primarily focusing on real-time monitoring and diagnosis of rotating machinery. This product is widely utilized in industries where equipment condition monitoring is critical for maintaining operational efficiency and preventing downtime.

Bently Nevada, a brand known for its advanced condition monitoring and protection solutions, integrates its vast expertise in industrial control systems into this product, ensuring reliability, precision, and long-term durability. The 190501-12-00-04 is part of Bently Nevada’s robust product line dedicated to improving machinery health management by providing high-fidelity data.

Product Advantages

-

High Precision and Accuracy

The device provides accurate readings of machinery vibrations, helping operators identify potential issues before they lead to costly failures. -

Ease of Installation

With straightforward setup procedures and compatibility with existing monitoring systems, installation is quick and efficient, minimizing downtime during deployment. -

Real-time Data Processing

This product ensures that data is continuously collected and analyzed, providing up-to-date insights into machinery health. -

Scalable System Integration

The device can easily be integrated into larger monitoring networks for centralized management of machinery health across multiple locations. -

Durability and Reliability

Designed for tough industrial environments, it ensures dependable operation even under harsh conditions. -

Advanced Diagnostics

With advanced diagnostics capabilities, the device can detect and analyze a wide variety of mechanical faults such as misalignments, imbalance, and bearing wear.

Technical Parameters

| Parameter | Specification |

|---|---|

| Dimensions (diameter) | 33 mm |

| Weight | 0.297 kg |

| Voltage | 24 V DC |

| Temperature Range | -20°C to +70°C |

| Input Frequency | 4-20 mA (Analog) |

| Output Type | Digital, Relay Outputs |

| Communication Protocol | Modbus RTU (RS-485) |

| Power Consumption | 5W |

| Protection Class | IP65 |

Product Applications

The Bently Nevada 190501-12-00-04 is primarily used in the following industries:

-

Oil and Gas

Used to monitor the condition of critical machinery such as pumps, compressors, and turbines. -

Power Generation

Essential for tracking the performance of rotating equipment, including generators and motors. -

Mining and Metallurgy

Provides machinery monitoring in mines and manufacturing plants to prevent equipment failure and ensure smooth operations. -

Water Treatment Plants

Used for continuous monitoring of pumps and other rotating machinery, enabling preventive maintenance schedules. -

Chemical Manufacturing

Ensures the reliability of pumps, mixers, and reactors in various chemical processes.

Compatible Models

The Bently Nevada 190501-12-00-04 can be used alongside the following models for expanded system monitoring:

-

Bently Nevada 330500-00-00-00

-

Bently Nevada 330100-00-00-00

-

Bently Nevada 350101-01-01-01

-

Bently Nevada 330120-00-00-00

-

Bently Nevada 330200-01-01-01

-

Bently Nevada 350802-01-01-01

Installation Instructions

-

Preparation

Ensure that all components are available and that the installation area is clean, dry, and free from electromagnetic interference. -

Mounting

Mount the device on a flat, vibration-free surface close to the equipment being monitored. The device must be securely fixed to avoid any unintended movement or vibrations. -

Wiring

Connect the wiring as per the product’s manual, ensuring that the power supply and signal connections are correct. -

Configuration

Using the software provided, configure the system for your specific equipment, setting thresholds and alarm parameters as needed. -

Testing

After installation, conduct a test to ensure the system is functioning properly, checking for accurate data readings and alarms. -

Calibration

Calibrate the device as necessary to align with the characteristics of the equipment being monitored.

FAQs

Q1: What is the purpose of the Bently Nevada 190501-12-00-04?

A1: The Bently Nevada 190501-12-00-04 is a vibration monitoring system designed to detect early signs of mechanical failure in rotating machinery, preventing costly downtime.

Q2: What industries benefit from using this product?

A2: Industries like oil and gas, power generation, chemical manufacturing, and water treatment all benefit from the system’s reliable machinery monitoring capabilities.

Q3: Can the Bently Nevada 190501-12-00-04 be used for machinery other than pumps?

A3: Yes, it is suitable for a wide range of rotating equipment, including turbines, compressors, mixers, and motors.

Q4: What kind of communication protocol does the device use?

A4: The device uses the Modbus RTU communication protocol over RS-485 for data transmission.

Q5: Is the Bently Nevada 190501-12-00-04 compatible with other Bently Nevada products?

A5: Yes, the device can be integrated with other Bently Nevada products, providing a scalable and comprehensive machinery monitoring solution.

Q6: How does the system alert operators to potential problems?

A6: The system provides real-time data and alarm notifications through relay outputs, allowing operators to take corrective action before issues escalate.

Recommended Related Models

Here are six other models from the Bently Nevada series that can complement the 190501-12-00-04:

| Model Number | Description |

|---|---|

| Bently Nevada 330500-00-00-00 | Vibration monitoring system for large machinery. |

| Bently Nevada 330100-00-00-00 | General-purpose vibration sensor for industrial use. |

| Bently Nevada 350101-01-01-01 | High-end condition monitoring system with data analysis features. |

| Bently Nevada 330120-00-00-00 | Vibration sensor for high-speed rotating machinery. |

| Bently Nevada 330200-01-01-01 | Digital signal conditioner for advanced vibration monitoring. |

| Bently Nevada 350802-01-01-01 | Comprehensive system for multi-channel vibration monitoring. |

Popular Bently Nevada Models

Here are eight other popular models from the Bently Nevada brand:

| Model Number | Description | Voltage | Weight | Dimensions |

|---|---|---|---|---|

| Bently Nevada 330500-00 | Vibration monitoring sensor for large machinery. | 24 V DC | 1 kg | 100 mm x 120 mm x 200 mm |

| Bently Nevada 330100-00 | General-purpose vibration monitoring system. | 24 V DC | 0.8 kg | 80 mm x 110 mm x 180 mm |

| Bently Nevada 350101-01 | Advanced machinery diagnostics system. | 24 V DC | 1.5 kg | 120 mm x 150 mm x 250 mm |

| Bently Nevada 330120-00 | High-precision vibration sensor for turbines. | 24 V DC | 0.6 kg | 85 mm x 95 mm x 175 mm |

| Bently Nevada 330200-01 | Digital signal conditioner for vibration sensors. | 24 V DC | 1.2 kg | 150 mm x 140 mm x 220 mm |

| Bently Nevada 350802-01 | Multi-channel vibration monitoring system. | 24 V DC | 2 kg | 160 mm x 170 mm x 230 mm |

| Bently Nevada 330400-00 | Vibration and temperature monitoring sensor. | 24 V DC | 1.3 kg | 100 mm x 120 mm x 210 mm |

| Bently Nevada 330800-00 | Condition monitoring system for rotating machines. | 24 V DC | 1.8 kg | 130 mm x 150 mm x 240 mm |

Bently Nevada 190501-12-00-04 CT Velocity Transducer

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||