| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

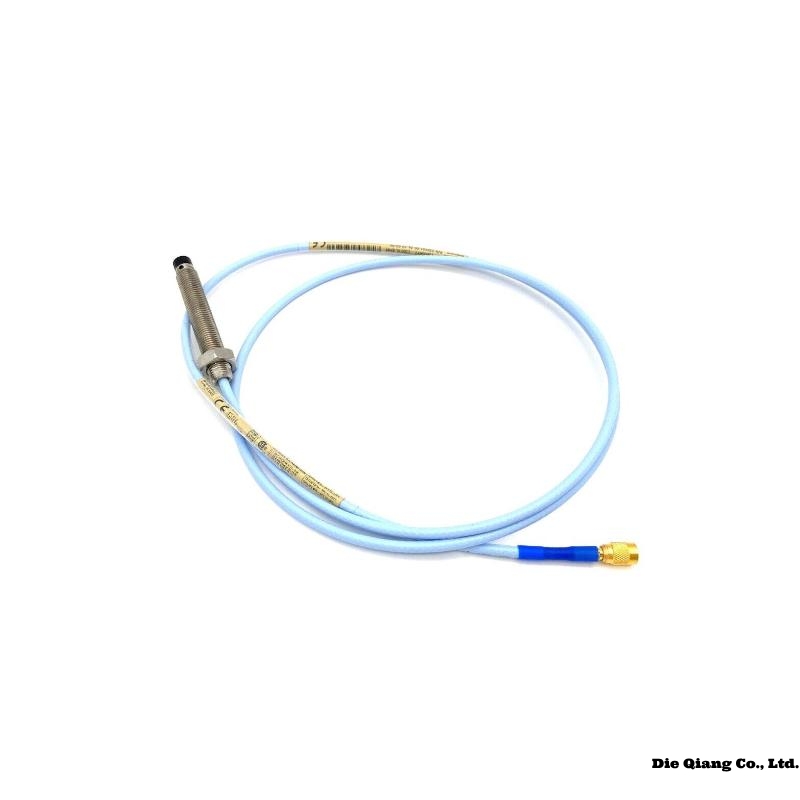

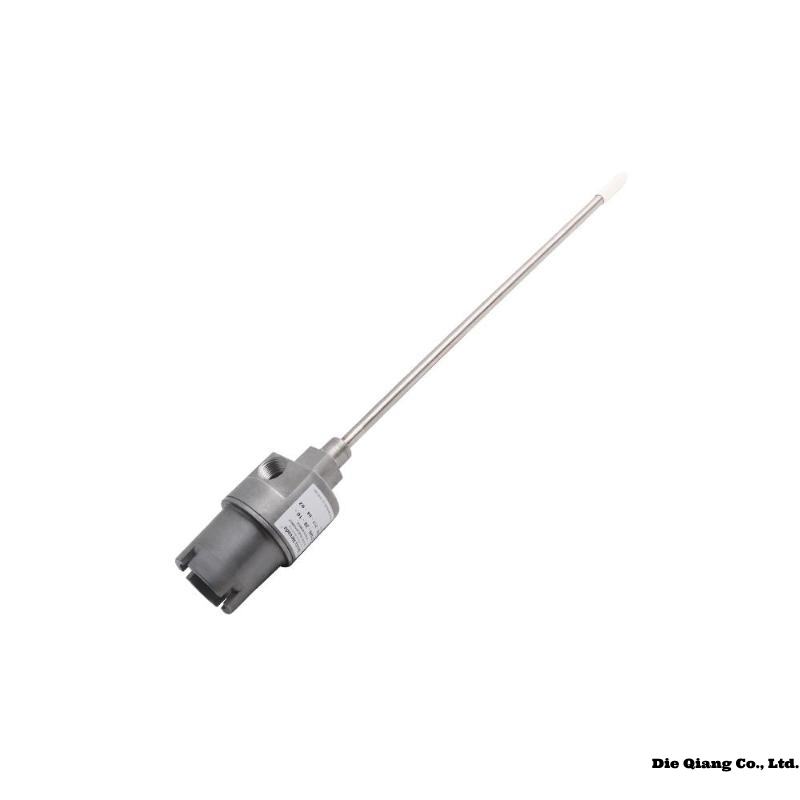

Bently Nevada 21000-16-05-00-096-00-02 Product Overview

The Bently Nevada 21000-16-05-00-096-00-02 is a high-performance vibration monitoring sensor designed for industrial machinery protection and condition monitoring. It is part of the Bently Nevada 21000 series, known for its reliability and precision in measuring vibration and speed in rotating equipment.

This sensor is widely used in power generation, oil & gas, and heavy industries to detect early signs of machinery faults, ensuring operational safety and minimizing downtime.

Product Advantages

- High Accuracy – Provides precise vibration measurements for critical machinery.

- Robust Construction – Designed to withstand harsh industrial environments.

- Wide Compatibility – Works seamlessly with Bently Nevada monitoring systems.

- Long Service Life – Built with durable materials for extended operational use.

- Easy Integration – Supports multiple communication protocols for system connectivity.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 21000-16-05-00-096-00-02 |

| Probe cable length | 0.5 m |

| Weight | 1.1 kg |

| Operating Voltage | 18-30 VDC |

| Output Signal | 4-20 mA / Digital (Modbus optional) |

| Frequency Range | 10 Hz – 10 kHz |

| Temperature Range | -40°C to +85°C |

| Protection Rating | IP67 |

| Mounting Type | Threaded / Magnetic Base |

Applications

- Gas & Steam Turbines – Monitors blade vibration and shaft displacement.

- Compressors & Pumps – Detects imbalance and misalignment issues.

- Electric Motors & Generators – Ensures smooth operation under load.

- Heavy Industrial Machinery – Prevents catastrophic failures in gearboxes and bearings.

Compatible Models for Integration

- Bently Nevada 3500/42M – Vibration Monitor

- Bently Nevada 3300/16 – Proximity Transducer

- Bently Nevada 1900/65A – Signal Conditioner

- Bently Nevada 2300/20 – Speed Sensor

Installation Instructions

- Mounting – Secure the sensor using the provided threaded or magnetic base.

- Wiring – Connect the power supply (18-30 VDC) and output signal cables.

- Calibration – Verify signal output using a calibration tool before operation.

- Testing – Perform a functional test to ensure proper vibration detection.

- Maintenance – Regularly inspect for dust, moisture, or physical damage.

Recommended 6 Related Models in the Same Series

| Model Number | Key Feature | Dimensions (mm) | Weight (kg) | Voltage (VDC) |

|---|---|---|---|---|

| 21000-16-05-00-097-00-02 | Enhanced frequency response | 50 x 50 x 120 | 0.5 | 18-30 |

| 21000-16-05-00-098-00-02 | High-temperature variant | 50 x 50 x 120 | 0.55 | 18-30 |

| 21000-16-05-00-099-00-02 | Explosion-proof design | 55 x 55 x 125 | 0.6 | 18-30 |

| 21000-16-05-01-096-00-02 | Wireless data transmission | 50 x 50 x 120 | 0.52 | 18-30 |

| 21000-16-05-02-096-00-02 | Dual-channel output | 60 x 60 x 130 | 0.7 | 18-30 |

| 21000-16-05-03-096-00-02 | Integrated temperature sensing | 50 x 50 x 125 | 0.58 | 18-30 |

8 Popular Bently Nevada Models (Cross-Series Recommendations)

| Model Number | Description | Dimensions (mm) | Weight (kg) | Voltage (VDC) | Key Application |

|---|---|---|---|---|---|

| 3500/22M | Vibration Monitor Module | 150 x 100 x 50 | 1.2 | 24 | Turbine Monitoring |

| 3300/25 | Proximity Sensor | 30 x 30 x 80 | 0.3 | 12-24 | Shaft Displacement |

| 1900/65A | Signal Conditioner | 120 x 80 x 40 | 0.8 | 24 | Vibration Analysis |

| 2300/20 | Speed Sensor | 40 x 40 x 90 | 0.4 | 12-30 | RPM Measurement |

| 3701/46 | Accelerometer | 25 x 25 x 60 | 0.2 | 18-30 | Bearing Vibration |

| 3500/92 | Communication Gateway | 200 x 150 x 60 | 2.0 | 24 | System Integration |

| 3300/16 | Proximity Transducer | 35 x 35 x 85 | 0.35 | 12-24 | Rotor Position Detection |

| 3500/42M | Vibration Monitoring System | 160 x 110 x 55 | 1.5 | 24 | Machinery Protection |

FAQ (Frequently Asked Questions)

Q1: What is the operating temperature range of the 21000-16-05-00-096-00-02?

A1: The sensor operates reliably between -40°C and +85°C.

Q2: Can this sensor be used in hazardous environments?

A2: The standard model is not explosion-proof. For hazardous areas, consider the 21000-16-05-00-099-00-02 variant.

Q3: What is the output signal type?

A3: It provides a 4-20 mA analog output, with optional digital (Modbus) communication.

Q4: How often should the sensor be calibrated?

A4: Annual calibration is recommended for optimal performance.

Q5: Is the sensor compatible with third-party monitoring systems?

A5: Yes, but signal conditioning may be required for non-Bently Nevada systems.

Q6: What is the expected lifespan of this sensor?

A6: Under normal conditions, the sensor lasts 8-10 years with proper maintenance.

Bently Nevada 21000-16-05-00-096-00-02 Proximity Probe Housing Assemblies

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

21000-16-05-00-096-00-02, Bently Nevada, Bently Nevada 21000-16-05-00-096-00-02, Proximity Probe Housing Assemblies