| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

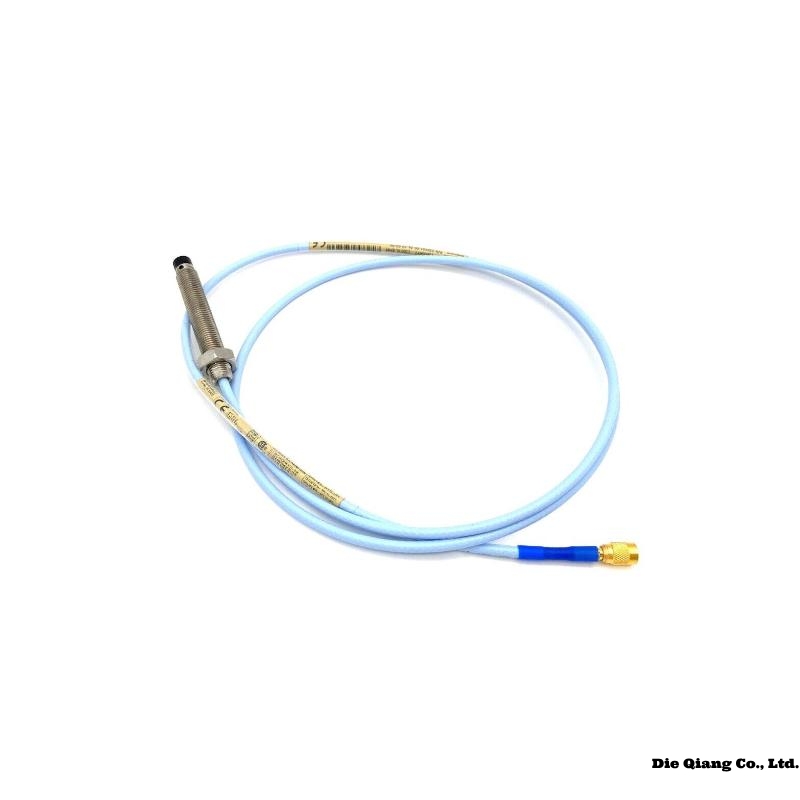

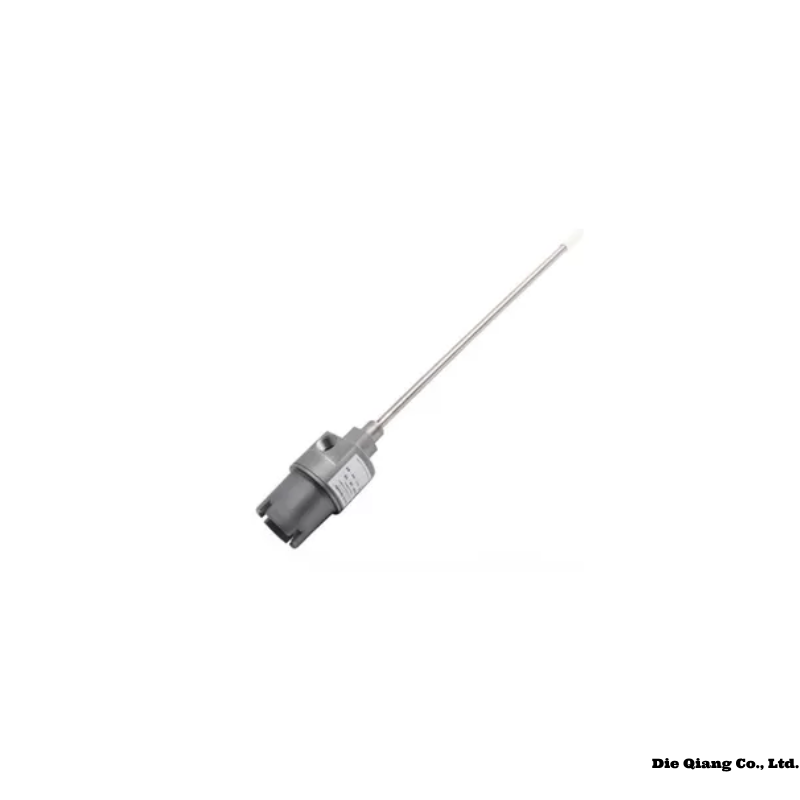

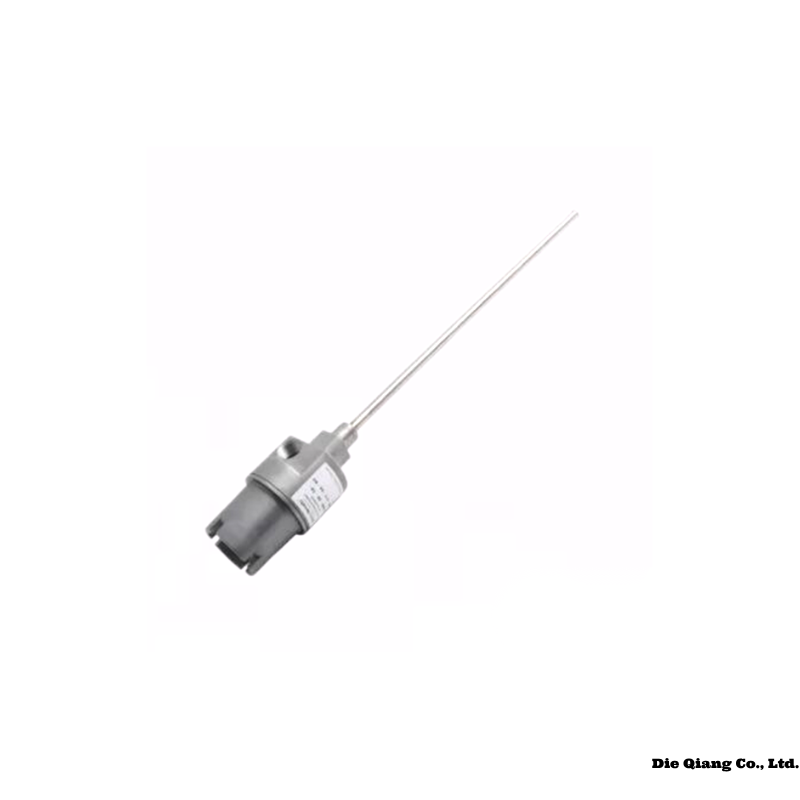

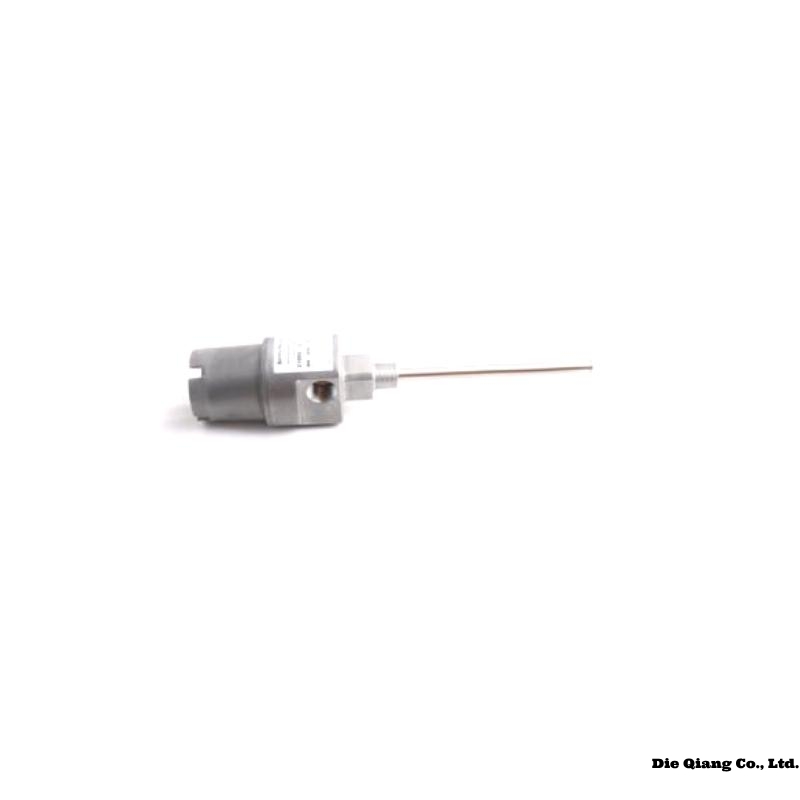

Product Introduction: Bently Nevada 21000-16-10-00-256-13-02

The Bently Nevada 21000-16-10-00-256-13-02 is a specialized condition monitoring sensor that forms part of the Bently Nevada series for industrial machinery monitoring systems. This device is designed to provide highly accurate measurements of vibration, displacement, and other parameters critical for the efficient operation and monitoring of rotating machinery. It integrates seamlessly with Bently Nevada’s monitoring systems to ensure optimal equipment performance, predict potential failures, and avoid costly downtime.

This sensor is a robust and reliable solution for continuous machinery monitoring in harsh industrial environments. It is widely used in power plants, oil and gas facilities, manufacturing plants, and any application requiring high-precision machinery health monitoring.

Product Advantages

-

High Accuracy: Offers precise measurement capabilities for vibration and displacement, ensuring early detection of faults.

-

Durability: Designed to operate in harsh industrial environments with high tolerance to temperature variations and mechanical stress.

-

Compatibility: Easily integrates into Bently Nevada’s broader machinery monitoring systems, providing a comprehensive health analysis.

-

Early Fault Detection: Enhances predictive maintenance by detecting potential failures before they occur, reducing unplanned downtime.

-

Ease of Installation: The device is designed for easy installation and can be retrofitted to most existing machinery without extensive modifications.

-

Cost-Effective: By preventing unexpected breakdowns, the sensor helps to significantly reduce maintenance costs and improve operational efficiency.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 21000-16-10-00-256-13-02 |

| Measurement Type | Vibration, Displacement |

| Power Supply | 24V DC |

| Operating Temperature | -40°C to +85°C |

| Mounting | Direct to machinery |

| Signal Output | 4-20 mA (Standard) |

| Weight | 1.5 kg |

| Dimensions | 125mm x 80mm x 50mm |

| Protection Class | IP65 |

| Accuracy | ±0.1mm for displacement |

| Frequency Range | 0-10 kHz |

Product Applications

The Bently Nevada 21000-16-10-00-256-13-02 sensor is used in a variety of applications, particularly those involving rotating equipment. It is ideal for:

-

Power Generation: Monitoring critical equipment like turbines and generators.

-

Oil and Gas: Used to monitor pumps, compressors, and other critical rotating machinery.

-

Industrial Manufacturing: Ensures optimal performance of machinery used in manufacturing processes.

-

Water Treatment Plants: Monitors pumps and motors to avoid mechanical failure.

Compatible Models

The Bently Nevada 21000-16-10-00-256-13-02 can be used with the following compatible models for enhanced machinery monitoring:

| Model Number | Description |

|---|---|

| 3500/33 | Vibration Monitor for rotating machinery |

| 3500/42 | 4-Channel Temperature Monitor |

| 3500/22 | 8-Channel Relay Module |

| 3500/71 | Communication Interface Module |

| 3500/25 | Tachometer Interface Module |

| 3300/12 | Proximity Sensor |

Installation Instructions

-

Prepare the Mounting Surface: Ensure the surface for sensor mounting is clean and free of debris. The sensor should be mounted firmly to minimize vibrations.

-

Positioning: Mount the sensor as close to the machine’s vibration source as possible, typically near the bearing housing.

-

Wiring: Connect the power supply to the sensor using a standard 24V DC source. The signal output should be wired to the monitoring system or control unit using a standard 4-20 mA current loop.

-

Calibration: After installation, calibrate the sensor according to the manufacturer’s instructions to ensure accurate readings.

-

Testing: Perform an initial test to verify the sensor is functioning as expected. Monitor the output for any abnormalities.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of the Bently Nevada 21000-16-10-00-256-13-02 sensor?

A1: The lifespan of this sensor is typically over 10 years, depending on environmental conditions and usage.

Q2: Can the Bently Nevada 21000-16-10-00-256-13-02 sensor be used in explosive environments?

A2: No, this sensor is not certified for use in explosive or hazardous environments. A certified model, such as the 3500 series, would be required for such applications.

Q3: What type of maintenance is required for the sensor?

A3: Routine inspections for any mechanical damage and cleaning of the sensor should be performed every 6 months. Calibration may also need to be done annually.

Q4: Is the Bently Nevada 21000-16-10-00-256-13-02 sensor compatible with other vibration monitoring systems?

A4: While designed for Bently Nevada systems, this sensor can work with other systems if they support standard output formats like 4-20 mA.

Q5: What is the power consumption of the Bently Nevada 21000-16-10-00-256-13-02 sensor?

A5: The power consumption is minimal, typically drawing around 20-30 mA at 24V DC.

Q6: Can the sensor be used in high-temperature environments?

A6: Yes, the sensor can operate in temperatures ranging from -40°C to +85°C, making it suitable for a wide range of industrial applications.

Recommended Related Models

Here are 6 models from the same series or related products for machinery health monitoring:

| Model Number | Description | Key Parameters |

|---|---|---|

| 3500/33 | Vibration Monitoring System | 4-20 mA Output, 24V DC, Frequency: 0-10 kHz |

| 3500/42 | 4-Channel Temperature Monitor | 4-20 mA Output, 24V DC, IP65 Protection |

| 3500/22 | Relay Module | 8 Relay Outputs, 24V DC |

| 3500/71 | Communication Interface Module | Ethernet/IP, Modbus RTU, RS-485 |

| 3500/25 | Tachometer Interface Module | 4-20 mA Output, 24V DC, IP65 |

| 3300/12 | Proximity Sensor | 4-20 mA Output, 24V DC, ±0.1mm Accuracy |

Additional 8 Popular Bently Nevada Models

Here are 8 additional popular models from Bently Nevada that are widely used in industrial applications:

| Model Number | Description | Key Parameters |

|---|---|---|

| 3500/40 | 4-Channel Signal Conditioner | 4-20 mA Output, 24V DC |

| 3500/72 | Vibration Protection System | 4-20 mA Output, 24V DC, IP65 Protection |

| 3500/33 | Vibration Monitoring System | 4-20 mA Output, 24V DC |

| 3500/20 | Relay Output Module | 8 Channels, 24V DC |

| 3300/10 | Vibration Sensor | 4-20 mA Output, 24V DC |

| 3300/11 | Proximity Probe | 4-20 mA Output, 24V DC |

| 3500/72 | Machinery Protection Monitoring | 4-20 mA Output, 24V DC |

| 3500/85 | Remote Monitoring System | Ethernet, 4-20 mA Output |

Bently Nevada 21000-16-10-00-256-13-02 Proximity Probe Housing Assemblies

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

21000-16-10-00-256-13-02, Bently Nevada, Bently Nevada 21000-16-10-00-256-13-02, Proximity Probe Housing Assemblies