| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

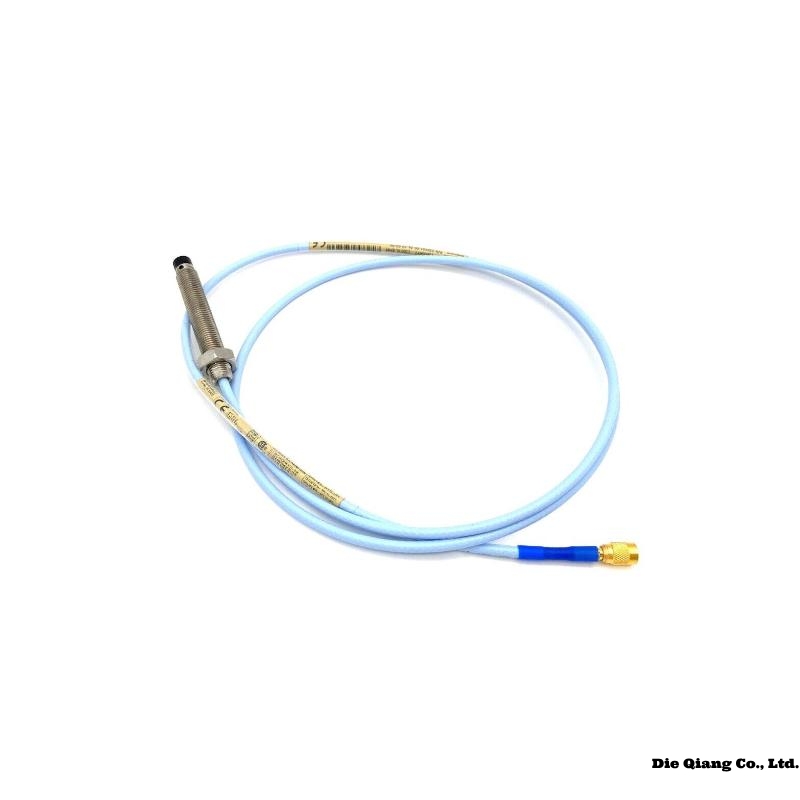

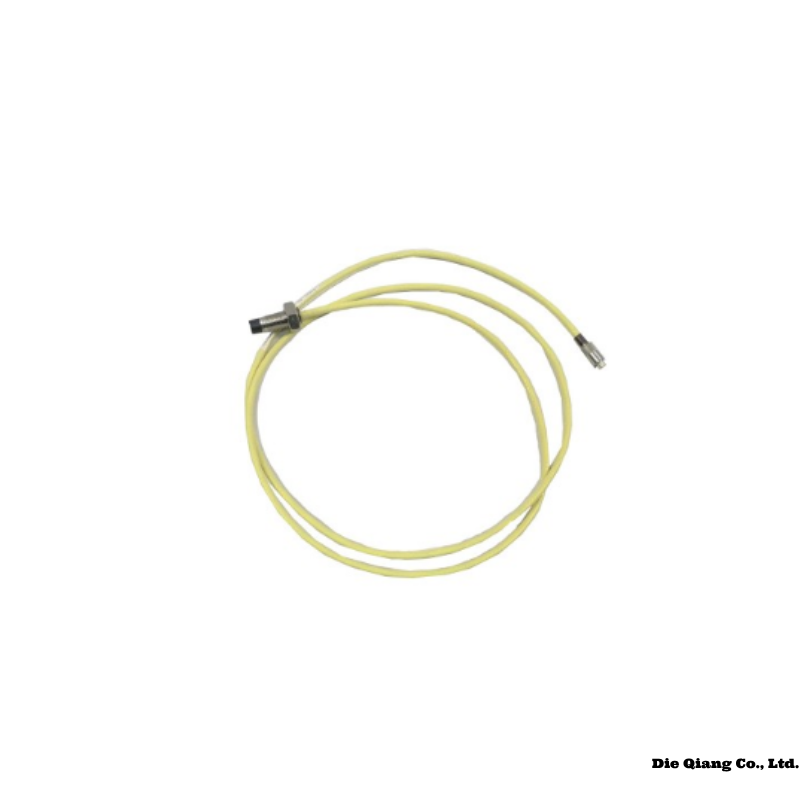

Bently Nevada 21504-000-008-05-02 Product Overview

The Bently Nevada 21504-000-008-05-02 is a high-performance vibration monitoring module designed for industrial machinery protection and condition monitoring. It is part of the 3500 Series by Bently Nevada, a trusted brand in predictive maintenance and machinery health solutions. This module provides reliable vibration measurement and fault detection for critical rotating equipment, ensuring operational safety and efficiency.

Product Advantages

- High Accuracy: Delivers precise vibration measurements for early fault detection.

- Robust Construction: Built to withstand harsh industrial environments (dust, moisture, and temperature variations).

- Easy Integration: Compatible with Bently Nevada’s 3500 monitoring system for seamless data acquisition.

- Real-Time Monitoring: Enables continuous tracking of machinery health to prevent unplanned downtime.

- Diagnostic Capabilities: Supports advanced diagnostics for identifying misalignment, imbalance, and bearing defects.

- Long Service Life: Designed for durability with high-quality components.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 21504-000-008-05-02 |

| Cable length | 0.5 m |

| Weight | 0.23kg |

| Operating Voltage | 18–30 VDC |

| Current Draw | 50 mA (typical) |

| Frequency Range | 10 Hz – 10 kHz |

| Output Signal | 4–20 mA, RS-485 Modbus |

| Operating Temp. | -40°C to +85°C (-40°F to +185°F) |

| Protection Rating | IP67 (Dust/Waterproof) |

Applications

The 21504-000-008-05-02 is widely used in:

- Gas & Steam Turbines – Monitors blade vibration and shaft misalignment.

- Compressors – Detects bearing wear and imbalance.

- Pumps & Motors – Identifies cavitation and mechanical looseness.

- Generators – Ensures stable operation by tracking rotor dynamics.

- Oil & Gas Industry – Protects critical machinery in refineries and pipelines.

Compatible Models (Recommended for System Integration)

- 3500/42M Proximity Transducer – For shaft displacement measurement.

- 3500/22M Accelerometer – High-frequency vibration sensing.

- 3500/15 Power Supply Module – Provides stable power to the monitoring system.

- 3500/92 Communication Gateway – Enables remote monitoring via Ethernet.

- 3500/25 Keyphasor Module – For phase reference and speed measurement.

Installation Instructions

- Mounting: Secure the module in a vibration-free location near the monitored machine.

- Wiring: Connect power (18–30 VDC) and signal output (4–20 mA/RS-485) as per the wiring diagram.

- Sensor Connection: Attach compatible vibration sensors (e.g., accelerometers or proximity probes).

- Calibration: Use Bently Nevada’s System 1 software for calibration and configuration.

- Testing: Verify signal integrity and alarm thresholds before full operation.

Recommended Similar/Related Models (Same Series)

| Model Number | Description | Dimensions | Weight | Voltage |

|---|---|---|---|---|

| 21504-000-008-05-01 | Vibration Monitor (4-Channel) | 150 mm × 90 mm × 40 mm | 0.5 kg | 18–30 VDC |

| 21504-000-008-05-03 | High-Temp Vibration Module | 160 mm × 95 mm × 45 mm | 0.6 kg | 24 VDC |

| 21504-000-008-05-04 | Explosion-Proof Vibration Monitor | 155 mm × 92 mm × 42 mm | 0.55 kg | 18–30 VDC |

| 21504-000-008-05-06 | Wireless Vibration Transmitter | 140 mm × 85 mm × 35 mm | 0.45 kg | Battery-Powered |

| 21504-000-008-05-07 | Dual-Channel Vibration Analyzer | 150 mm × 90 mm × 40 mm | 0.5 kg | 24 VDC |

| 21504-000-008-05-08 | Industrial Vibration Relay Module | 145 mm × 88 mm × 38 mm | 0.48 kg | 18–30 VDC |

Top 8 Popular Bently Nevada Models (Other Series)

| Model Number | Description | Dimensions | Weight | Voltage |

|---|---|---|---|---|

| 3300 XL 8mm Proximity Probe | Shaft Displacement Sensor | 80 mm × 18 mm Ø | 0.2 kg | -18 to -24 VDC |

| 3500/22M Accelerometer | High-Frequency Vibration Sensor | 60 mm × 30 mm Ø | 0.3 kg | 18–30 VDC |

| 1900/65A Seismic Transmitter | Low-Frequency Vibration Monitor | 120 mm × 75 mm × 50 mm | 0.7 kg | 24 VDC |

| 3500/42M Proximity Monitor | Bearing Vibration Module | 150 mm × 90 mm × 40 mm | 0.5 kg | 18–30 VDC |

| 3701/20-01-01-00 Pressure Sensor | Dynamic Pressure Monitoring | 100 mm × 50 mm × 30 mm | 0.4 kg | 10–32 VDC |

| 3500/92 Communication Gateway | Ethernet Data Interface | 200 mm × 120 mm × 60 mm | 1.2 kg | 24 VDC |

| 3300/16-11-02-01-00-00 Temp Sensor | Bearing Temperature Probe | 50 mm × 10 mm Ø | 0.1 kg | N/A |

| 3500/25 Keyphasor Module | Speed/Phase Reference Module | 150 mm × 90 mm × 40 mm | 0.5 kg | 18–30 VDC |

FAQ (Frequently Asked Questions)

Q1: What is the operating temperature range of the 21504-000-008-05-02?

A1: It operates from -40°C to +85°C (-40°F to +185°F).

Q2: Can this module be used in hazardous areas?

A2: No, for explosive environments, consider the 21504-000-008-05-04 (ATEX-certified).

Q3: What communication protocols are supported?

A3: It supports 4–20 mA analog output and RS-485 Modbus.

Q4: Is calibration required after installation?

A4: Yes, calibration via System 1 software is recommended for optimal performance.

Q5: What is the IP rating of this module?

A5: It has an IP67 rating (dustproof and waterproof).

Q6: Can it monitor both velocity and acceleration?

A6: Yes, it supports velocity (mm/s) and acceleration (g) measurements.

Bently Nevada 21504-000-008-05-02 Standard Mount Proximity Probe 8mm

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

21504-000-008-05-02, Bently Nevada, Bently Nevada 21504-000-008-05-02, Standard Mount Proximity Probe 8mm