| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

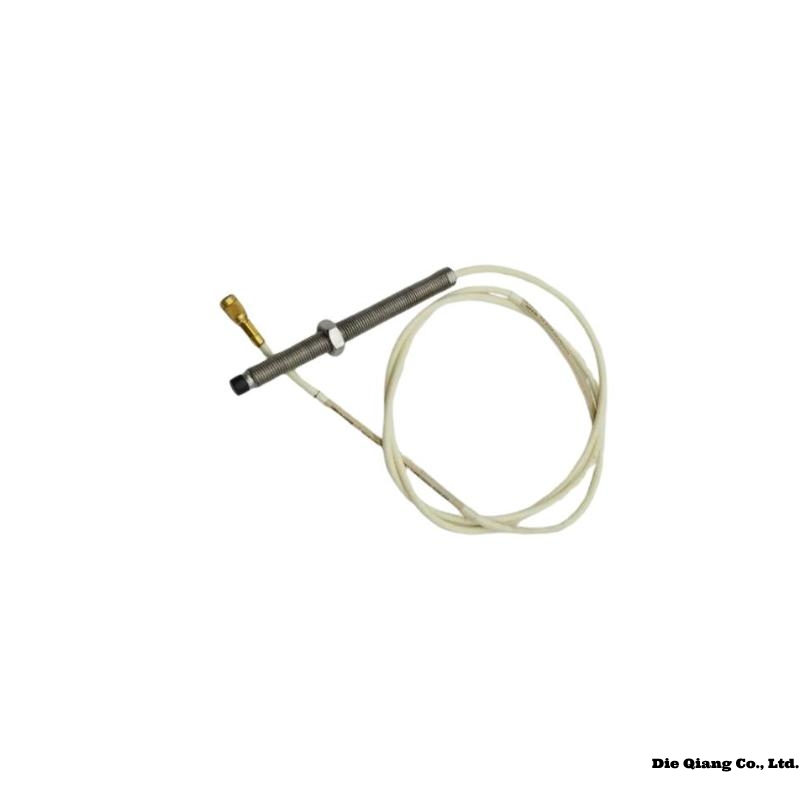

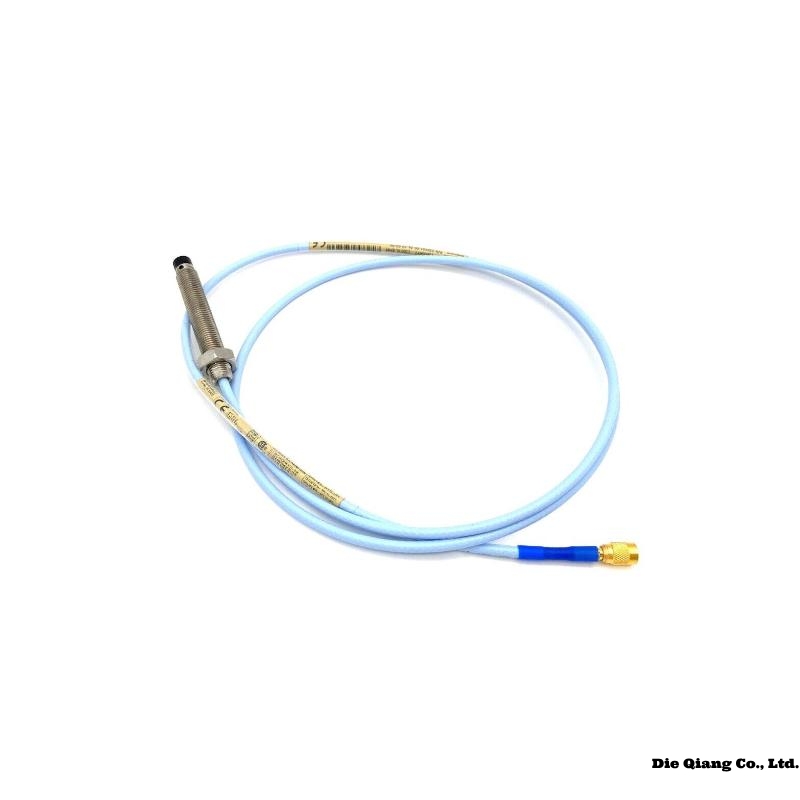

The Bently Nevada 21504-000-008-10-02 is a highly advanced vibration sensor used in industrial control systems. This sensor plays a crucial role in monitoring the condition of machinery, particularly rotating equipment such as motors, turbines, and pumps. With its precise measurement capabilities, it helps in preventing equipment failure and minimizing downtime by providing early detection of potential mechanical issues. This product is often utilized in industries such as oil and gas, power generation, and manufacturing.

Product Advantages

-

High Accuracy: The sensor provides precise vibration measurements, which helps operators to detect issues at an early stage and avoid unexpected breakdowns.

-

Robust Construction: Designed for use in harsh industrial environments, the 21504-000-008-10-02 is built to withstand extreme conditions such as high temperatures, moisture, and vibration.

-

Ease of Installation: The sensor can be easily installed on rotating equipment, reducing maintenance time and ensuring continuous monitoring without excessive downtime.

-

Cost Efficiency: Early detection of faults leads to significant cost savings by preventing costly repairs and improving the lifespan of the machinery.

-

Compatibility: This sensor is designed to integrate seamlessly with Bently Nevada’s existing range of condition monitoring systems, offering enhanced reliability.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | Bently Nevada 21504-000-008-10-02 |

| Sensor Type | Vibration Sensor |

| Operating Temperature | -40°C to +85°C |

| Weight | 1.2 kg |

| Cable length | 1m |

| Power Supply | 24 VDC |

| Output | 4-20 mA |

| Mounting | Flange Mounted |

| Material | Stainless Steel |

| Response Frequency | 0.1 Hz to 1 kHz |

| Safety Standards | CE, UL |

Product Applications

The Bently Nevada 21504-000-008-10-02 is widely used in:

-

Power Generation Plants: Monitoring turbines and generators.

-

Oil and Gas Industry: Ensuring the operational reliability of pumps, compressors, and other critical equipment.

-

Manufacturing: Used to monitor the condition of rotating machinery, such as motors and fans, to ensure efficiency and minimize downtime.

-

Mining: Vibration sensors are crucial in monitoring mining equipment for potential failures.

Recommended Models from the Same Series or Related Models

| Model Number | Description | Key Specifications |

|---|---|---|

| Bently Nevada 21505-000-008-10-02 | Vibration Sensor for High-Speed Machines | 0.1 Hz to 2 kHz, 24 VDC, Stainless Steel |

| Bently Nevada 21506-000-008-10-02 | Vibration Sensor for General Applications | 4-20 mA Output, Flange Mounted |

| Bently Nevada 21507-000-008-10-02 | Accelerometer for High-Temperature Environments | -40°C to 125°C, 4-20 mA Output |

| Bently Nevada 21503-000-008-10-02 | Vibration Monitoring System | 24 VDC, 0.1 Hz to 500 Hz |

| Bently Nevada 21504-000-009-10-02 | High Precision Vibration Sensor | 4-20 mA Output, -20°C to +85°C |

| Bently Nevada 21508-000-008-10-02 | Industrial Vibration Sensor | 0.5 Hz to 2 kHz, 24 VDC, Stainless Steel |

Other Popular Bently Nevada Models

| Model Number | Description | Key Specifications |

|---|---|---|

| Bently Nevada 3501 | Vibration Monitoring System | 24 VDC, 4-20 mA Output, 0.1 Hz to 1 kHz |

| Bently Nevada 330500 | Machine Condition Monitoring | 4-20 mA Output, Stainless Steel |

| Bently Nevada 330180 | Vibration Transducer | -40°C to +85°C, 0.1 Hz to 500 Hz |

| Bently Nevada 3300 | Vibration Monitoring System | 24 VDC, 0.1 Hz to 1 kHz |

| Bently Nevada 330730 | Accelerometer for Rotating Equipment | 4-20 mA Output, Flange Mounted |

| Bently Nevada 3500/22 | Vibration Monitoring System | 24 VDC, 4-20 mA Output, Stainless Steel |

| Bently Nevada 330550 | Machinery Protection System | 4-20 mA Output, 0.1 Hz to 1 kHz |

| Bently Nevada 3500/42 | Machinery Protection System | -40°C to +85°C, 4-20 mA Output |

Installation Instructions

-

Mounting Location: Ensure the sensor is installed at a vibration-prone area of the machinery for accurate readings.

-

Power Supply: Connect the 24 VDC supply to the sensor’s power input terminal.

-

Sensor Orientation: The sensor should be aligned with the machine’s axis to detect vibrations correctly.

-

Signal Output: Connect the sensor output (4-20 mA) to the monitoring system or controller.

-

Safety: Verify that the machine is powered down before installation and follow all safety procedures.

FAQ Section

Q1: What is the recommended installation method for the Bently Nevada 21504-000-008-10-02 sensor? A1: The sensor should be flange-mounted to ensure stable installation and accurate vibration measurements.

Q2: What is the sensor’s output range? A2: The sensor provides a 4-20 mA output for easy integration with monitoring systems.

Q3: Can the Bently Nevada 21504-000-008-10-02 be used in high-temperature environments? A3: Yes, it can withstand temperatures ranging from -40°C to +85°C, making it suitable for most industrial environments.

Q4: What industries typically use this vibration sensor? A4: It is used in power generation, oil and gas, manufacturing, and mining industries.

Q5: How does the sensor detect mechanical failures? A5: The sensor detects abnormal vibrations, which are indicative of potential mechanical failures, such as misalignments, imbalance, or bearing wear.

Q6: Is it compatible with other Bently Nevada monitoring systems? A6: Yes, it is designed to integrate seamlessly with other Bently Nevada monitoring systems, ensuring reliable operation across a wide range of applications.

Bently Nevada 21504-000-008-10-02 Proximity Sensor developed

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||