| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

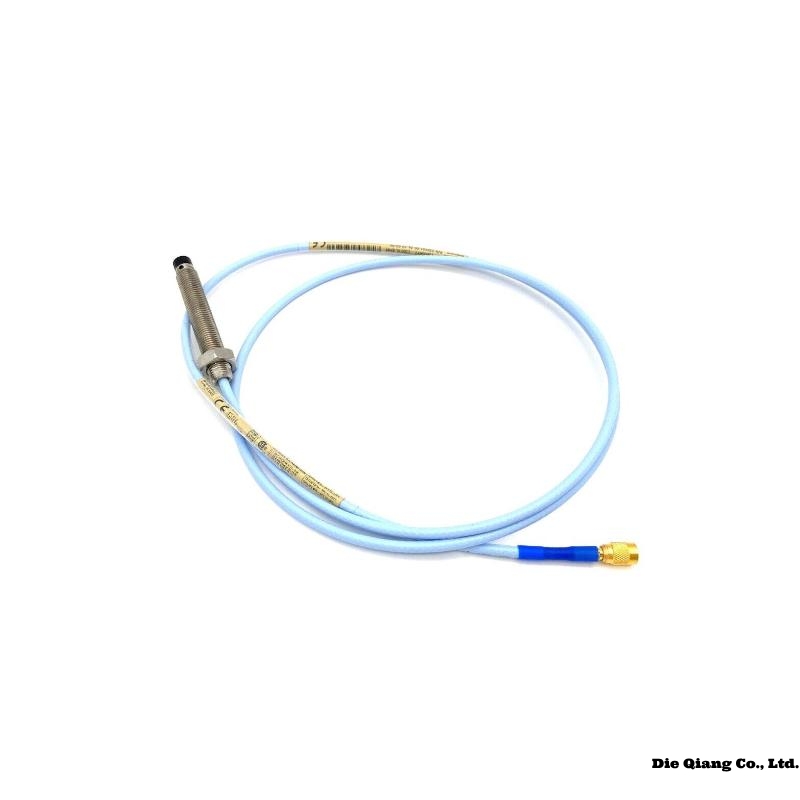

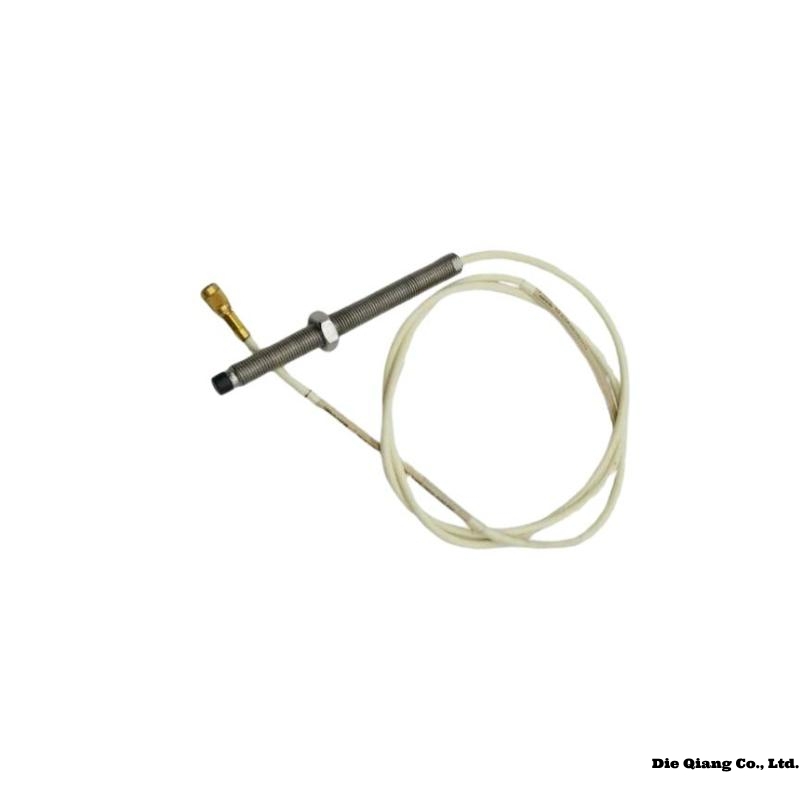

Product Introduction of Bently Nevada 21504-000-040-05-02

The Bently Nevada 21504-000-040-05-02 is a high-performance vibration and condition monitoring sensor designed to offer real-time, accurate, and reliable data for monitoring industrial machinery. It is widely used in industries where machinery performance is critical to operational success, such as power generation, oil and gas, manufacturing, and chemical processing. This sensor is engineered to detect vibrations in rotating machinery, enabling users to take timely corrective actions before issues can escalate, minimizing downtime and reducing maintenance costs.

Advantages of Bently Nevada 21504-000-040-05-02

-

High Precision: The sensor provides high-resolution measurements, which ensures precise monitoring and early fault detection in machinery.

-

Durability: Built to withstand harsh industrial environments, the sensor is resistant to temperature fluctuations, moisture, and mechanical stress.

-

Real-time Monitoring: Offers continuous monitoring, which allows for predictive maintenance, preventing unexpected failures and optimizing maintenance schedules.

-

Ease of Integration: Designed to seamlessly integrate with other Bently Nevada monitoring systems, ensuring a comprehensive solution for machine health monitoring.

-

Scalable: It can be scaled for use across different machines in large-scale industrial operations, providing flexibility and long-term value.

-

Cost-Effective: By detecting faults early, this sensor helps reduce the need for costly repairs and downtime, contributing to operational cost savings.

Technical Specifications

| Parameter | Specification |

|---|---|

| Dimensions | Contact Customer Service |

| Weight | Contact Customer Service |

| Voltage | 24V DC |

| Output | 4-20mA |

| Temperature Range | -40°C to +85°C |

| Frequency Range | 10 Hz to 1 kHz |

| Mounting Type | Threaded or Magnetic |

| Operating Pressure | Up to 10 bar |

| Protection Class | IP67 |

Product Applications

The Bently Nevada 21504-000-040-05-02 is ideal for applications in industries that require continuous monitoring of machinery performance. Common applications include:

-

Power Generation: Monitoring of turbines, generators, and motors.

-

Oil and Gas: Condition monitoring of pumps, compressors, and drilling equipment.

-

Manufacturing: Monitoring of conveyor belts, motors, and critical machinery.

-

Chemical Processing: Vibration monitoring in pumps, mixers, and reactors.

Compatible Models for Use with Bently Nevada 21504-000-040-05-02

The Bently Nevada 21504-000-040-05-02 is compatible with the following models:

-

Bently Nevada 3500/33: Vibration monitoring system that integrates well with the sensor.

-

Bently Nevada 3500/42: Dynamic Pressure Transducer for further machinery diagnostics.

-

Bently Nevada 3500/22M: Machinery Protection System that pairs with the vibration sensor for comprehensive condition monitoring.

-

Bently Nevada 3300: Vibration transducer offering enhanced performance for more complex monitoring needs.

-

Bently Nevada 3300/01: Displacement probe for additional vibration detection.

-

Bently Nevada 3500/22: Vibration monitoring system that is ideal for large-scale installations.

Installation Instructions

-

Prepare the Mounting Surface: Ensure the machine surface is clean, smooth, and free of debris. The sensor should be mounted on a rigid surface to avoid interference with measurements.

-

Attach the Sensor: Using the provided threaded mounting bolts or magnetic base, secure the sensor to the designated area.

-

Connect the Wiring: Connect the sensor’s wiring to the monitoring system according to the provided wiring diagram.

-

Power Up: Apply 24V DC power to the sensor and ensure the monitoring system is properly receiving the data.

-

Calibration: Follow the manufacturer’s calibration procedure to ensure accurate readings.

-

Test Functionality: Run a test to verify the sensor’s correct operation within the system.

Recommended Similar or Related Models

| Model | Description | Voltage | Dimensions | Weight |

|---|---|---|---|---|

| Bently Nevada 21504-000-040-06-02 | A similar vibration sensor with enhanced frequency range | 24V DC | 12 cm x 7.5 cm | 0.75 kg |

| Bently Nevada 21505-000-040-05-02 | For use in higher temperature environments | 24V DC | 10 cm x 7 cm | 0.65 kg |

| Bently Nevada 21504-000-030-04-02 | A compact version of the 21504 with similar performance | 24V DC | 9 cm x 7 cm | 0.5 kg |

| Bently Nevada 21507-000-040-02-03 | For more complex vibration monitoring tasks | 24V DC | 13 cm x 8 cm | 1.0 kg |

| Bently Nevada 21506-000-040-04-02 | Designed for low-noise environments | 24V DC | 11 cm x 7 cm | 0.55 kg |

| Bently Nevada 21508-000-050-05-01 | Higher sensitivity for industrial machinery | 24V DC | 15 cm x 9 cm | 1.2 kg |

Popular Models from Bently Nevada

| Model | Voltage | Dimensions | Weight | Application |

|---|---|---|---|---|

| Bently Nevada 3500/33 | 24V DC | 15 cm x 12 cm | 2.0 kg | Vibration monitoring |

| Bently Nevada 3500/42 | 24V DC | 14 cm x 10 cm | 1.8 kg | Pressure transducer |

| Bently Nevada 3500/22M | 24V DC | 20 cm x 15 cm | 3.5 kg | Machinery protection |

| Bently Nevada 3300 | 24V DC | 12 cm x 9 cm | 1.0 kg | Vibration measurement |

| Bently Nevada 3300/01 | 24V DC | 11 cm x 8 cm | 0.8 kg | Displacement sensor |

| Bently Nevada 3500/22 | 24V DC | 20 cm x 14 cm | 2.8 kg | Vibration monitoring |

| Bently Nevada 2300 | 24V DC | 18 cm x 14 cm | 2.0 kg | Machinery condition |

| Bently Nevada 3300/10 | 24V DC | 14 cm x 10 cm | 1.2 kg | Vibration sensor |

FAQs for Bently Nevada 21504-000-040-05-02

Q1: What environments is the Bently Nevada 21504-000-040-05-02 suitable for?

A1: The sensor is suitable for industrial environments with extreme temperatures, moisture, and mechanical stresses, including power generation, manufacturing, and chemical plants.

Q2: What voltage does the Bently Nevada 21504-000-040-05-02 operate on?

A2: It operates on 24V DC, ensuring compatibility with most industrial systems.

Q3: How do I calibrate the sensor?

A3: Calibration can be done by following the manufacturer’s guidelines provided in the installation manual. It is essential to calibrate periodically for optimal performance.

Q4: Can the Bently Nevada 21504-000-040-05-02 be used in hazardous environments?

A4: Yes, the sensor is designed for use in a variety of hazardous environments, including high-temperature and high-pressure conditions.

Q5: Is the sensor compatible with other Bently Nevada monitoring equipment?

A5: Yes, it is fully compatible with other Bently Nevada systems, such as the 3500 and 3300 series, to provide a comprehensive condition monitoring solution.

Q6: What maintenance is required for the Bently Nevada 21504-000-040-05-02?

A6: The sensor requires minimal maintenance. Regular checks for dust or debris and periodic recalibration are recommended to maintain optimal performance.

Bently Nevada 21504-000-040-05-02 5mm and 8mm Standard Mount Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

21504-000-040-05-02, 5mm and 8mm Standard Mount Probe, Bently Nevada, Bently Nevada 21504-000-040-05-02