| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

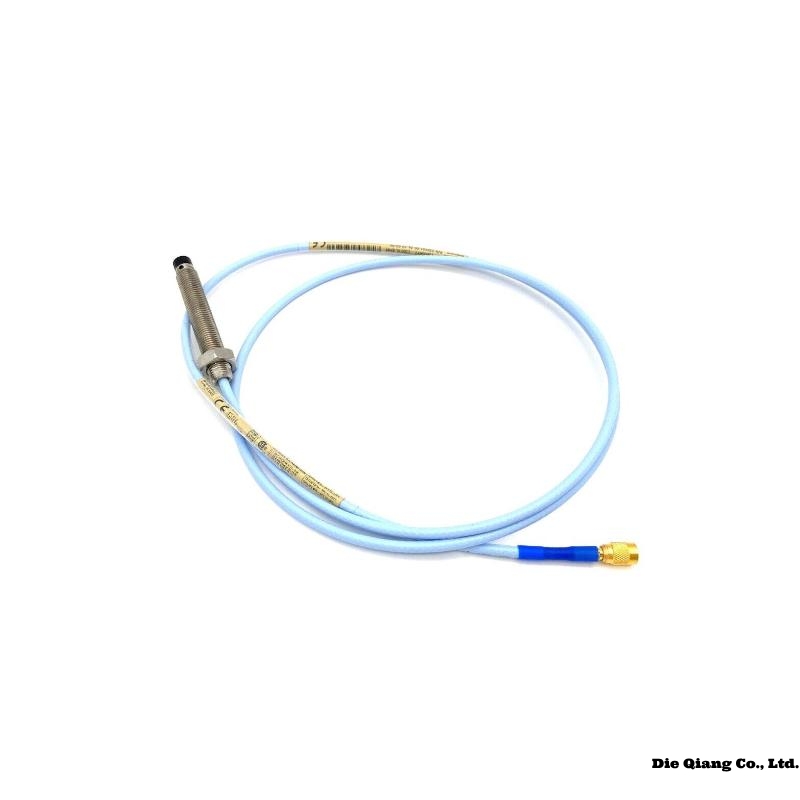

Bently Nevada 21505-000-040-10-02 Product Overview

The Bently Nevada 21505-000-040-10-02 is a high-performance vibration sensor used in industrial control and monitoring applications. It is part of the Bently Nevada 21505 series of sensors, designed to deliver accurate vibration measurement and monitoring of critical machinery. This product is typically used in industries such as power generation, oil and gas, mining, and manufacturing, where machinery health monitoring is essential for operational efficiency and safety.

Advantages

-

High Precision: The 21505-000-040-10-02 provides highly accurate and reliable vibration data, essential for predictive maintenance and performance monitoring of machinery.

-

Durability: Built to withstand harsh industrial environments, the sensor is highly durable, ensuring long-term reliability even in extreme conditions such as high temperatures and vibration levels.

-

Ease of Integration: The sensor integrates easily with existing monitoring systems, particularly the Bently Nevada machinery monitoring systems, to provide real-time data and insights.

-

Versatility: Suitable for a wide range of industrial applications, this sensor is ideal for rotating machinery, pumps, motors, and turbines, among others.

-

Long Operational Life: Thanks to its robust construction and advanced technology, the sensor offers long-term reliability and minimal maintenance requirements.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 21505-000-040-10-02 |

| Measurement Type | Vibration sensor |

| Mounting | Bolt-on or adhesive attachment |

| Frequency Range | 1 to 10,000 Hz |

| Sensitivity | 100 mV/g |

| Voltage Supply | 18 to 30 VDC |

| Output Signal | 4-20 mA (current loop) |

| Cable length | 5 m |

| Weight | Contact Customer Service |

| Operating Temperature | -40°C to +85°C |

| Protection Class | IP67 |

Applications

The Bently Nevada 21505-000-040-10-02 is used primarily for:

-

Condition Monitoring: Monitoring the vibration levels of critical machinery to predict failure and optimize maintenance schedules.

-

Machinery Health Monitoring: Used in rotating machinery applications such as turbines, pumps, and compressors to ensure optimal performance.

-

Predictive Maintenance: The sensor provides the data necessary for implementing predictive maintenance strategies, preventing unplanned downtime.

-

Safety Applications: Vibration data is essential for ensuring machinery operates within safe parameters, minimizing the risk of equipment failure or damage.

Compatible Models

The following Bently Nevada models are compatible with the 21505-000-040-10-02 sensor for monitoring and control purposes:

-

Bently Nevada 3500/22M – Machinery health monitor

-

Bently Nevada 3500/42M – Vibration monitoring system

-

Bently Nevada 3500/53M – Machine condition monitoring system

-

Bently Nevada 21505-000-040-10-01 – Vibration sensor with a similar configuration

-

Bently Nevada 21505-000-040-10-03 – Higher frequency version of the same sensor

-

Bently Nevada 21505-000-040-10-04 – Alternative sensor with additional signal conditioning

Installation Instructions

-

Mounting: The sensor should be mounted securely on a flat surface using bolts or adhesive. Ensure that the mounting surface is clean and free of any debris to avoid interference with the sensor’s performance.

-

Wiring: Connect the sensor to the monitoring system following the specified wiring diagram. Ensure proper polarity when connecting the voltage supply and output signal.

-

Calibration: Once installed, calibrate the sensor according to the system requirements. The calibration process may involve adjusting sensitivity levels to match the vibration profiles of the machinery being monitored.

-

Testing: Perform a system check to ensure that the sensor is correctly integrated and transmitting accurate data. Regular testing and calibration may be required to maintain optimal sensor performance.

Recommended Models (Related or Same Series)

| Model | Type | Voltage Supply | Frequency Range | Weight | Dimensions (L x W x H) |

|---|---|---|---|---|---|

| 21505-000-040-10-01 | Vibration Sensor | 18-30 VDC | 1 to 10,000 Hz | 0.3 kg | 100 x 60 x 50 mm |

| 21505-000-040-10-03 | Vibration Sensor | 18-30 VDC | 1 to 10,000 Hz | 0.3 kg | 100 x 60 x 50 mm |

| 21505-000-040-10-04 | Vibration Sensor | 18-30 VDC | 1 to 10,000 Hz | 0.3 kg | 100 x 60 x 50 mm |

| 3500/22M | Vibration Monitoring System | 18-30 VDC | 1 to 5,000 Hz | 1.5 kg | 300 x 200 x 100 mm |

| 3500/42M | Vibration Monitoring System | 18-30 VDC | 1 to 10,000 Hz | 1.8 kg | 320 x 210 x 110 mm |

| 3500/53M | Machine Condition Monitoring | 18-30 VDC | 1 to 10,000 Hz | 2.0 kg | 330 x 220 x 120 mm |

Popular Bently Nevada Models

| Model | Type | Voltage Supply | Frequency Range | Weight | Dimensions (L x W x H) |

|---|---|---|---|---|---|

| 3500/22M | Machinery Monitoring System | 18-30 VDC | 1 to 5,000 Hz | 1.5 kg | 300 x 200 x 100 mm |

| 3500/42M | Vibration Monitoring System | 18-30 VDC | 1 to 10,000 Hz | 1.8 kg | 320 x 210 x 110 mm |

| 3500/53M | Machine Condition Monitoring | 18-30 VDC | 1 to 10,000 Hz | 2.0 kg | 330 x 220 x 120 mm |

| 3500/11 | Vibration Transducer System | 18-30 VDC | 1 to 5,000 Hz | 0.7 kg | 120 x 90 x 50 mm |

| 3500/15 | Signal Conditioning System | 18-30 VDC | 1 to 10,000 Hz | 0.8 kg | 130 x 100 x 60 mm |

| 3500/41 | Proximity Transducer System | 18-30 VDC | 1 to 1,500 Hz | 0.5 kg | 140 x 110 x 70 mm |

| 21505-000-040-10-05 | Vibration Sensor | 18-30 VDC | 1 to 5,000 Hz | 0.3 kg | 100 x 60 x 50 mm |

| 21505-000-040-10-06 | Vibration Sensor | 18-30 VDC | 1 to 10,000 Hz | 0.3 kg | 100 x 60 x 50 mm |

Frequently Asked Questions (FAQs)

Q1: What is the primary application of the Bently Nevada 21505-000-040-10-02?

A1: The sensor is primarily used for vibration monitoring in industrial machinery to detect early signs of mechanical failure and optimize maintenance schedules.

Q2: What industries can benefit from using this sensor?

A2: Industries such as power generation, oil and gas, mining, and manufacturing can benefit from using this sensor for machinery health monitoring.

Q3: How should the sensor be installed?

A3: The sensor should be mounted securely on a clean, flat surface and connected to the monitoring system according to the wiring diagram.

Q4: What is the operating temperature range of the sensor?

A4: The operating temperature range of the Bently Nevada 21505-000-040-10-02 is between -40°C to +85°C.

Q5: Can this sensor be used with other Bently Nevada monitoring systems?

A5: Yes, the sensor is fully compatible with other Bently Nevada systems, such as the 3500/22M and 3500/42M, for integrated monitoring.

Q6: How often does the sensor need to be calibrated?

A6: Calibration should be performed during installation and periodically thereafter, depending on the specific operational conditions and system requirements.

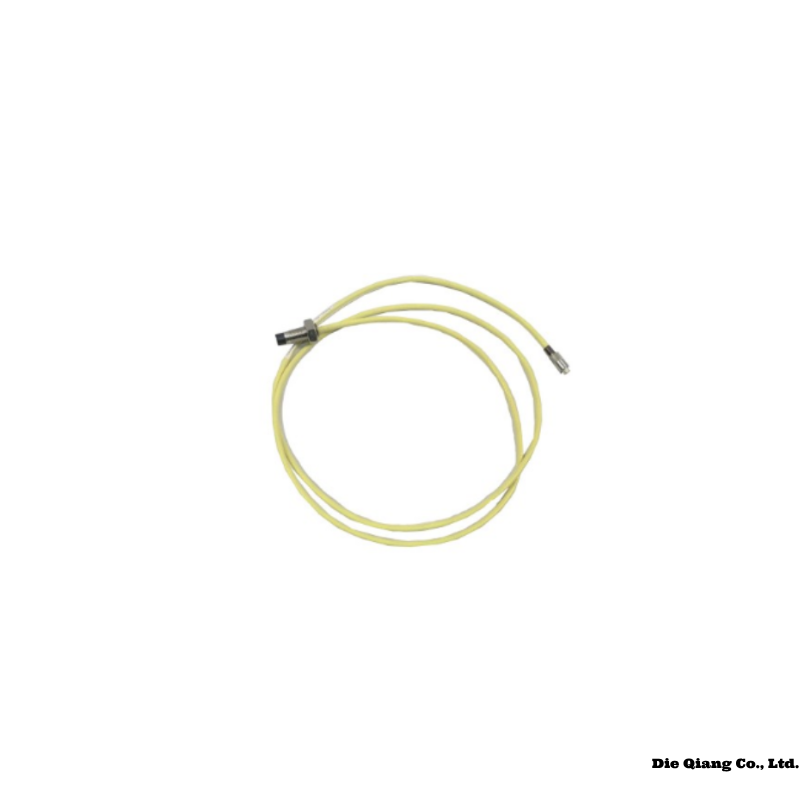

Bently Nevada 21505-000-040-10-02 5mm and 8mm Standard Mount Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

21505-000-040-10-02, 5mm and 8mm Standard Mount Probe, Bently Nevada, Bently Nevada 21505-000-040-10-02