| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Bently Nevada 330101-00-08-05-02-00

Product Introduction

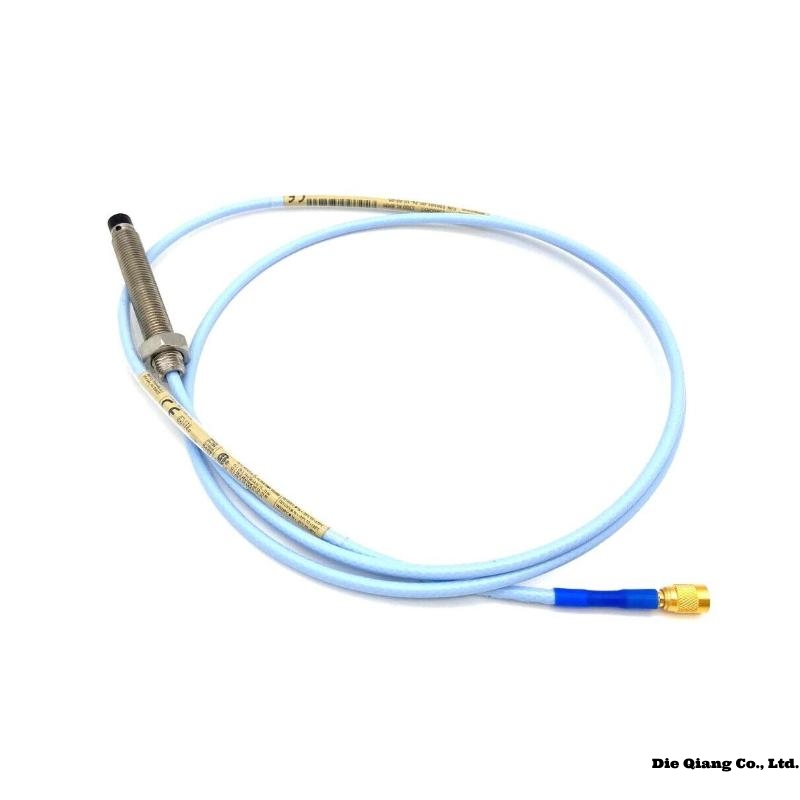

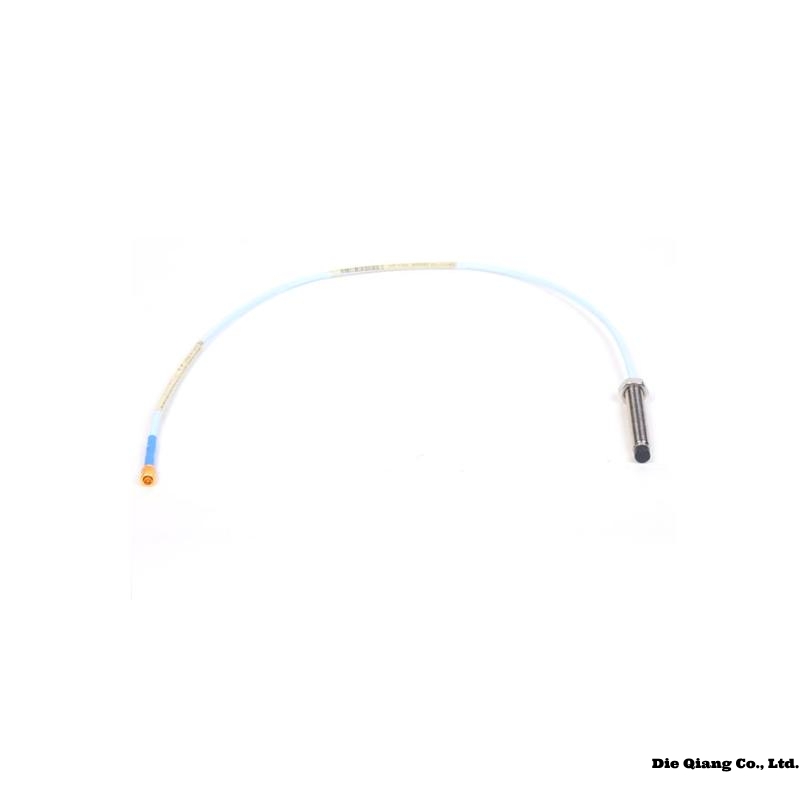

The Bently Nevada 330101-00-08-05-02-00 is a highly reliable proximity probe assembly designed for precise vibration and position monitoring in critical machinery applications. As part of the 3300 XL Proximity Transducer System, this probe is engineered to deliver accurate, real-time data essential for predictive maintenance and protection of rotating equipment such as turbines, compressors, pumps, and motors.

The 330101 series is known for its high durability and industry-leading measurement accuracy. Built to operate in challenging industrial environments, this model offers robust protection against temperature extremes, electromagnetic interference, and mechanical stress.

Its advanced design meets the strict requirements of the API 670 standard, ensuring it integrates seamlessly with Bently Nevada’s condition monitoring systems.

Product Advantages

-

API 670 Compliant: Fully adheres to the API 670 standard for machinery protection systems.

-

Exceptional Accuracy: Provides high-resolution and linear measurements even in extreme environmental conditions.

-

Robust Design: Engineered with rugged materials, ensuring long operational life and mechanical durability.

-

Temperature and EMI Resistant: Offers superior resistance to temperature variation, vibration, and electromagnetic interference.

-

Wide Compatibility: Works seamlessly with 3300 XL systems and other compatible Bently Nevada monitoring devices.

-

Ease of Maintenance: Modular design facilitates quick installation and replacement without system downtime.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330101-00-08-05-02-00 |

| Probe Length | 200 mm (8.0 in) |

| Cable Length | 0.5 m |

| Connector Type | Miniature coaxial with ClickLoc™ locking |

| Probe Material | AISI 304 stainless steel |

| Weight | 0.246 kg |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Linear Range | 2 mm (80 mils) |

| Output Voltage | -200 mV/mil (-7.87 mV/µm) ±5% |

| Power Supply | -24 V DC nominal (supplied via monitor) |

| Mounting Thread | 3/8-24 UNF or M10 x 1.0 (custom options available) |

| Vibration Limit | 50 g peak |

| Shock Limit | 5000 g peak |

| Humidity | 95% non-condensing |

| Protection Rating | IP65 |

| Compliance | API 670, CE, RoHS |

Applications

The Bently Nevada 330101-00-08-05-02-00 is commonly used in the following applications:

-

Steam and Gas Turbines: Monitoring shaft vibration and displacement for safe operation.

-

Centrifugal Compressors: Detecting misalignment and imbalance conditions.

-

Industrial Pumps: Tracking bearing and shaft behavior to prevent unplanned outages.

-

Electric Motors and Generators: Measuring dynamic and static shaft positions.

-

Gearboxes: Evaluating gear mesh behavior and ensuring stable transmission.

-

Petrochemical Plants and Power Stations: Ensuring plant reliability through continuous vibration monitoring.

Compatible Models

The 330101-00-08-05-02-00 probe is compatible with the following Bently Nevada systems:

-

3300 XL Extension Cables (330130 series)

-

3300 XL Proximitor Sensors (330180 series)

-

3500 Series Machinery Protection Systems

-

3300 Series Monitors and Racks

-

7200 Series Monitors

-

Bently Nevada ADRE Systems

-

System 1† Condition Monitoring Software

Installation Instructions

-

Preparation:

-

Ensure the equipment is powered off and secured.

-

Verify probe orientation and mounting location are in accordance with machine specifications.

-

-

Mounting the Probe:

-

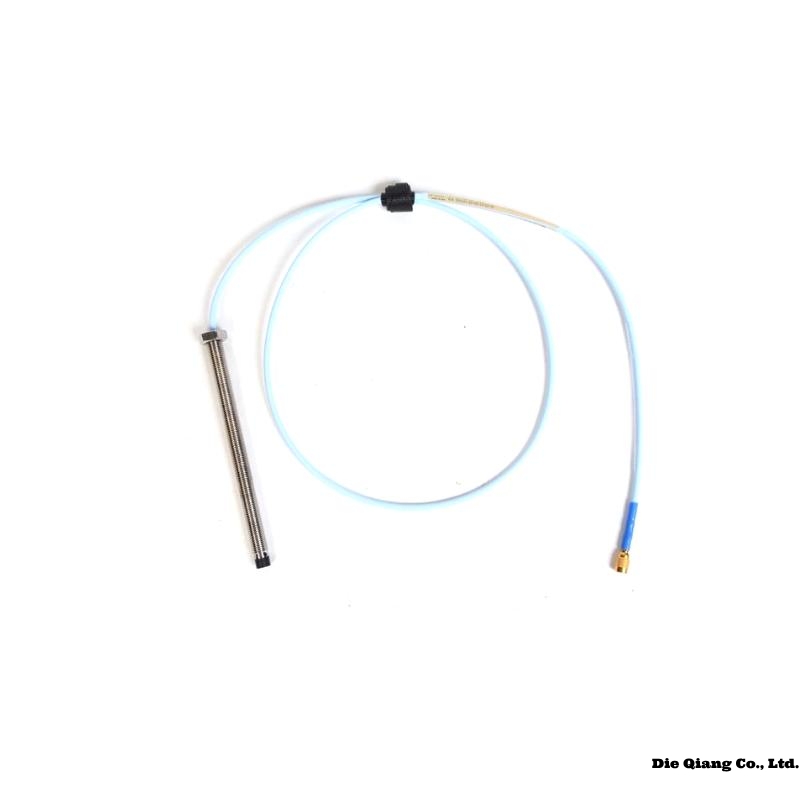

Insert the probe into the mounting sleeve.

-

Thread the probe into the mounting hole using the proper torque (as specified in the manual).

-

Leave a proper gap between the probe tip and the shaft (typically 1 mm).

-

-

Cable Connection:

-

Connect the extension cable to the probe using the ClickLoc™ connector.

-

Route and secure the cable to prevent mechanical wear or EMI exposure.

-

-

Connecting the Proximitor Sensor:

-

Attach the other end of the extension cable to the 3300 XL Proximitor Sensor.

-

Confirm correct polarity and secure all connectors.

-

-

System Calibration:

-

Power up the system and use the calibration tools to fine-tune output.

-

Verify output voltage and linearity across the target displacement range.

-

-

Final Inspection:

-

Double-check all mounting points.

-

Ensure cables are secure and not exposed to abrasion.

-

Related Models (Same Series or Similar Use)

| Model Number | Cable Length | Probe Length | Thread Type | Output Sensitivity | Temp Range |

|---|---|---|---|---|---|

| 330101-00-06-10-02-00 | 6.0 m | 100 mm | 3/8-24 UNF | -200 mV/mil | -35 to +177°C |

| 330101-00-12-10-02-00 | 12.0 m | 100 mm | 3/8-24 UNF | -200 mV/mil | -35 to +177°C |

| 330101-00-05-05-02-00 | 5.0 m | 50 mm | 3/8-24 UNF | -200 mV/mil | -35 to +177°C |

| 330101-00-15-05-02-00 | 15.0 m | 50 mm | 3/8-24 UNF | -200 mV/mil | -35 to +177°C |

| 330101-00-09-05-02-00 | 9.0 m | 50 mm | 3/8-24 UNF | -200 mV/mil | -35 to +177°C |

| 330101-00-10-05-02-00 | 10.0 m | 50 mm | 3/8-24 UNF | -200 mV/mil | -35 to +177°C |

Popular Bently Nevada Models

| Model | Description | Voltage | Dimensions (mm) | Weight (kg) | Key Features |

|---|---|---|---|---|---|

| 330180-91-00 | 3300 XL Proximitor Sensor | 24V DC | 89 x 64 x 25 | 0.23 | API 670, matched to 330101 probe |

| 3500/42M | Proximitor Seismic Monitor | 24V DC | 241 x 24 x 241 | 0.80 | 4-channel, buffered output |

| 3500/22M | Transient Data Interface | 24V DC | 241 x 24 x 241 | 0.75 | High-speed digital data gateway |

| 330130-040-00-00 | Extension Cable for Probes | N/A | Custom Length | 0.45 | Compatible with 330101 series |

| 330103-00-08-10-02-00 | 8mm Proximity Probe | N/A | 200 mm | 0.50 | Designed for larger shaft sizes |

| 3701/40 | TDI with Advanced Signal Processing | 24V DC | 250 x 25 x 250 | 1.00 | Real-time machine diagnostics |

| 190501 | Velocity Transducer | Self-gen | 64 x 30 | 0.30 | No external power required |

| 3500/15 | Power Supply Module | 85–264 VAC | 241 x 24 x 241 | 0.60 | For 3500 series rack system |

Frequently Asked Questions (FAQs)

Q1: What is the primary function of the 330101-00-08-05-02-00 proximity probe?

A1: The primary function is to measure the distance between the probe tip and a conductive surface, typically the rotating shaft of machinery, to monitor vibration and shaft position.

Q2: Can this probe operate in hazardous environments?

A2: Yes, the 330101 series is designed with rugged stainless-steel construction and is rated for use in industrial environments with high vibration, EMI, and temperature variation.

Q3: Is the probe compatible with older Bently Nevada systems?

A3: Yes, the probe maintains backward compatibility with legacy systems such as the 7200 series and integrates fully with the 3300 XL and 3500 systems.

Q4: How do I determine the correct gap voltage during installation?

A4: The correct gap voltage is typically -8 VDC, which corresponds to a 1 mm gap. Adjust the probe depth during installation to achieve this value, as verified using a Bently Nevada calibration tool.

Q5: How frequently should the probe be inspected or replaced?

A5: Inspection should be part of routine maintenance, typically every 6 to 12 months depending on the operating environment. Replacement is only necessary if degradation in output or physical damage is observed.

Q6: What type of cable is used with this probe?

A6: The 330101-00-08-05-02-00 uses a coaxial extension cable (330130 series) with a ClickLoc™ locking connector for secure attachment and EMI resistance.

Bently Nevada 330101-00-08-05-02-00 3300 XL 8 mm Proximity Probes

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 8 mm Proximity Probes, 330101-00-08-05-02-00, Bently Nevada, Bently Nevada 330101-00-08-05-02-00