| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

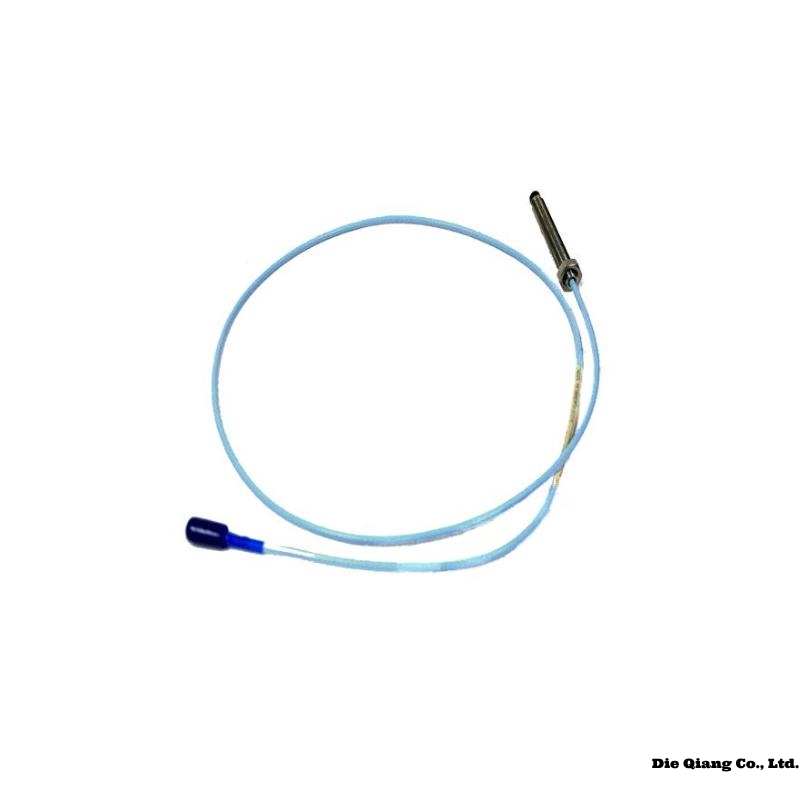

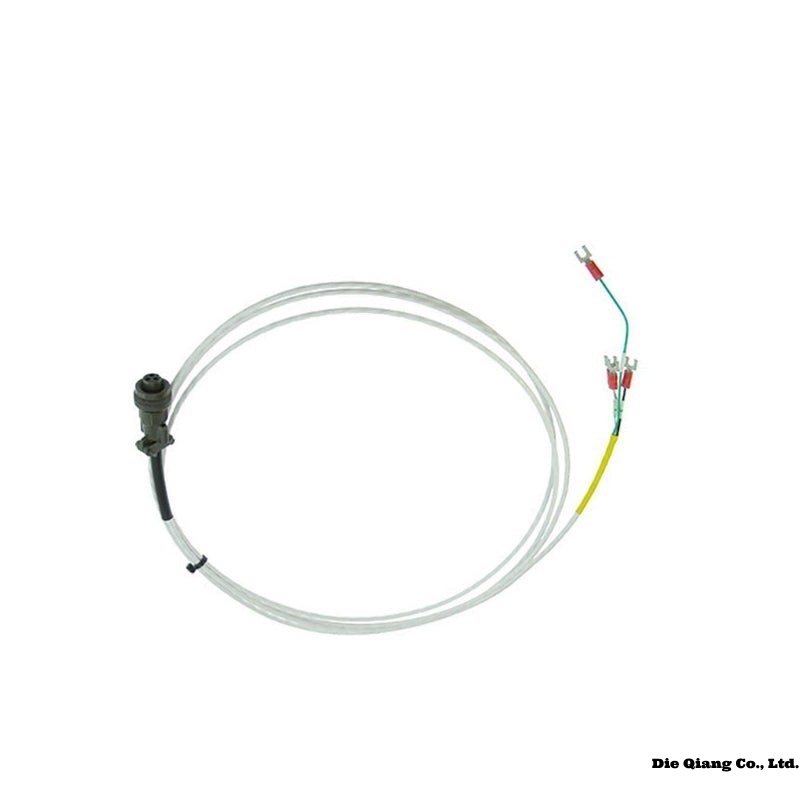

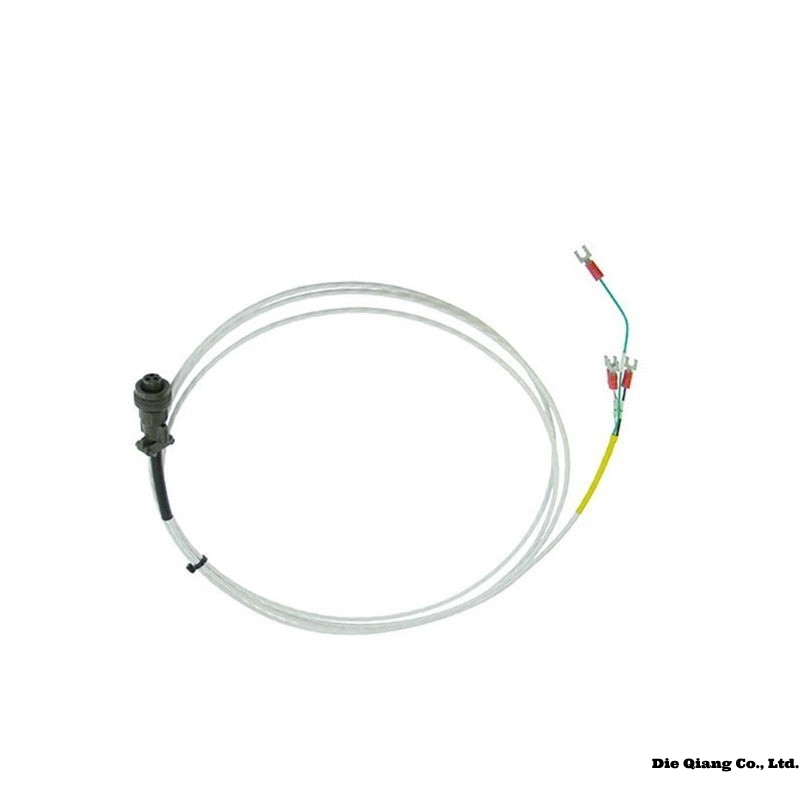

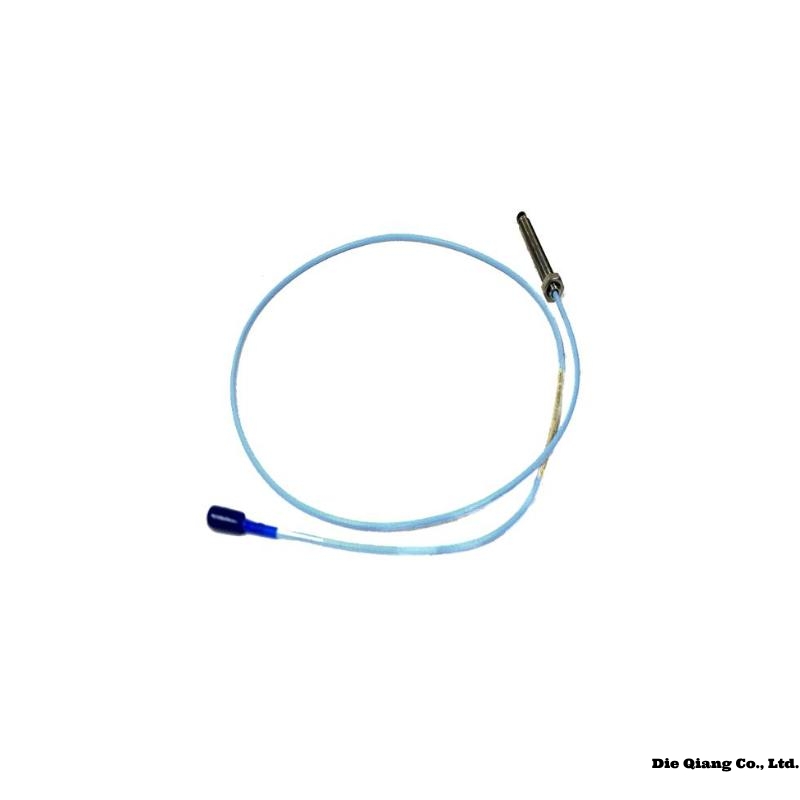

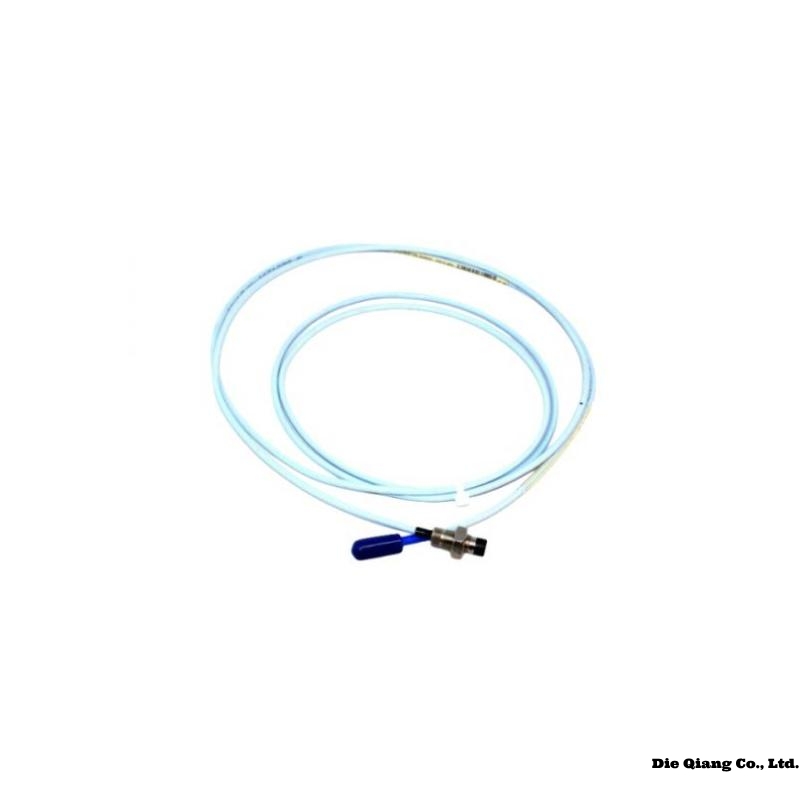

Bently Nevada 330101-00-08-20-12-05

Product Introduction

The Bently Nevada 330101-00-08-20-12-05 is a high-performance proximity probe used in vibration and position monitoring systems, forming a part of the renowned 3300 XL Proximitor® System developed by Bently Nevada, a GE brand. This system is known for its reliable condition monitoring of rotating machinery, ensuring plant safety and asset longevity.

This specific model—330101-00-08-20-12-05—includes a proximity probe with a 0.8-meter (approximately 2.62 feet) probe cable, a 2-meter extension cable, and a 5-meter system length. It is engineered to comply with rigorous industrial standards, offering exceptional durability and signal integrity even under extreme environmental conditions.

The probe operates with Bently Nevada’s Proximitor® sensors to detect shaft position and vibration relative to the probe tip, enabling accurate diagnostics and predictive maintenance for rotating machinery such as turbines, compressors, motors, and pumps.

Product Advantages

-

Superior Signal Integrity: Engineered with enhanced shielding to minimize signal degradation and interference in high-noise environments.

-

Rugged Industrial Design: Withstands harsh environments with high resistance to mechanical stress, moisture, oil, and chemical exposure.

-

Consistent Performance: Provides stable and repeatable measurements over long operating periods, reducing the need for recalibration.

-

Modular System Compatibility: Fully compatible with 3300 XL Proximitor® systems, allowing seamless integration and upgrades.

-

Non-Contact Measurement: Provides precise vibration and displacement readings without physical contact, preventing equipment wear.

-

Long-Term Cost Savings: Reduces unplanned downtime and maintenance costs through early fault detection.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330101-00-08-20-12-05 |

| Probe Tip Material | Polyphenylene Sulfide (PPS) |

| Body Style | Threaded Cylinder |

| Probe Length | 80 mm (8 = 8.0 mm) |

| Nominal Linear Range | 2 mm (±1 mm) |

| Frequency Response | 0 to 10 kHz |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Output Voltage | -24 VDC nominal |

| Input Power Requirements | -17 VDC to -27 VDC |

| Probe Diameter | 8 mm |

| Thread Size | 3/8-24 UNF-2A |

| Weight | 0.246 kg |

| Cable length | 2 m |

| Operating Temperature | -35°C to +120°C |

| Storage Temperature | -51°C to +177°C |

| Humidity | 100% condensing, sealed construction |

| Pressure Resistance | Up to 500 psi with appropriate housing |

| Connector Type | Miniature coaxial, gold-plated |

Applications

The Bently Nevada 330101-00-08-20-12-05 proximity probe system is used in a wide range of industrial applications where continuous machinery health monitoring is critical. Common applications include:

-

Steam and gas turbines

-

Industrial compressors

-

Large electric motors and generators

-

Gearboxes and couplings

-

Centrifugal and axial flow pumps

-

Blowers and fans in refineries and petrochemical plants

-

Paper mills, steel mills, and mining machinery

This model is especially suitable for detecting shaft vibration, axial thrust, and differential expansion in high-value rotating assets.

Compatible Models

This probe is designed for use with the following models within the 3300 XL system:

-

3300 XL Proximitor Sensor (part number 330180)

-

3300 XL Extension Cable (matching length specifications)

-

3500 Series Monitoring Systems (such as 3500/42M and 3500/22M)

-

330104 series probes (alternative sizes)

-

330130 series extension cables (interchangeable length)

-

330400 and 330425 Dual Vibration/Position Monitors

All components must match the system length to ensure calibrated output.

Installation Instructions

-

Mounting the Probe:

Thread the probe into the mounting location using the 3/8-24 UNF thread. Torque according to specifications (typically 5–7 N·m). Ensure that the probe is perpendicular to the shaft surface. -

Gap Adjustment:

Using a dial gauge or signal tester, adjust the gap voltage to the appropriate value (typically -10 VDC). This ensures the probe is within the linear range for accurate measurement. -

Cable Routing:

Secure the extension cable away from sources of EMI. Avoid sharp bends and keep cable radius ≥25 mm. Use grounding clamps if required by system grounding practices. -

Connect to Proximitor®:

Plug the probe and extension cable into the 3300 XL Proximitor sensor. Ensure tight coaxial connections to avoid signal loss. -

Final Checks:

Verify signal response using a signal checker or oscilloscope. Check for proper grounding, power input, and system integration. -

Environmental Sealing:

Use appropriate conduit fittings or enclosures if installed in hazardous or outdoor environments.

6 Related Models (Same Series)

| Model Number | Probe Length | System Length | Cable Length | Thread Size | Voltage Range |

|---|---|---|---|---|---|

| 330101-00-05-10-02-00 | 50 mm | 2 m | 1 m | 3/8-24 UNF | -24 VDC |

| 330101-00-10-10-02-00 | 100 mm | 2 m | 1 m | 3/8-24 UNF | -24 VDC |

| 330101-00-05-05-01-00 | 50 mm | 1 m | 0.5 m | 1/4-28 UNF | -24 VDC |

| 330101-00-08-15-05-00 | 80 mm | 5 m | 1.5 m | 3/8-24 UNF | -24 VDC |

| 330101-00-12-05-02-00 | 120 mm | 2 m | 0.5 m | M10 x 1 | -24 VDC |

| 330101-00-08-20-05-00 | 80 mm | 5 m | 2 m | 3/8-24 UNF | -24 VDC |

8 Popular Bently Nevada Models

| Model | Description | Dimensions (mm) | Weight | Voltage |

|---|---|---|---|---|

| 330104-00-05-10-02-00 | Proximity Probe, 50 mm, 1.0 m cable | Ø8 x 50 | 90 g | -24 VDC |

| 330130-040-00-00 | Extension Cable, 4.0 m | Length: 4000 | 150 g | N/A |

| 330180-91-05 | XL Proximitor Sensor | 76 x 51 x 25 | 300 g | -24 VDC |

| 3500/42M | Proximitor Seismic Monitor Module | 120 x 30 x 180 | 500 g | 18–30 VDC |

| 3500/22M | Transient Data Interface Module | 120 x 30 x 180 | 510 g | 18–30 VDC |

| 330500 | Velomitor Piezoelectric Velocity Sensor | Ø25 x 80 | 210 g | Self-powered |

| 330780-51-00 | High Temp Velocity Sensor | Ø27 x 85 | 220 g | Self-powered |

| 330105-02-12-10-02-00 | Proximity Probe, 120 mm, 2.0 m cable | Ø8 x 120 | 95 g | -24 VDC |

Product FAQ (Q&A Format)

Q1: What is the primary use of the 330101-00-08-20-12-05 proximity probe?

A1: It is used for measuring the vibration and position of rotating machinery shafts to monitor machine condition and prevent mechanical failure.

Q2: Can this probe be used with the 3500/42M module?

A2: Yes, this probe is fully compatible with the 3500/42M Proximitor Monitor as long as the system cable lengths match the calibration of the Proximitor sensor.

Q3: Is the probe suitable for hazardous environments?

A3: While the probe itself is not intrinsically safe, it can be used in hazardous areas when installed inside certified enclosures or in combination with intrinsic safety barriers.

Q4: How do I determine the correct gap voltage during installation?

A4: The recommended gap voltage is approximately -10 VDC. You can adjust the gap using a signal checker or voltmeter to bring the reading to the correct value.

Q5: Can I cut or shorten the extension cable?

A5: No, modifying the cable length will alter the system calibration and lead to inaccurate measurements. Use only pre-calibrated components with matching system length.

Q6: What is the expected service life of the probe?

A6: When installed properly in industrial environments, the probe typically has a service life of 5–10 years, though this can vary based on operating conditions.

Bently Nevada 330101-00-08-20-12-05 3300 XL Proximity Transducer Probe 8mm

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL Proximity Transducer Probe 8mm, 330101-00-08-20-12-05, Bently Nevada, Bently Nevada 330101-00-08-20-12-05