| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

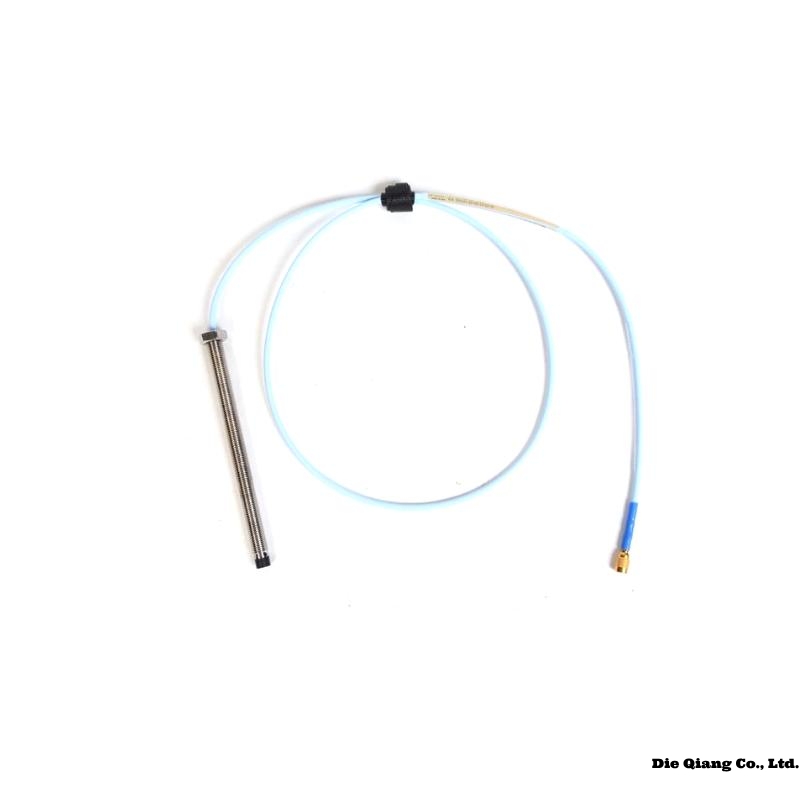

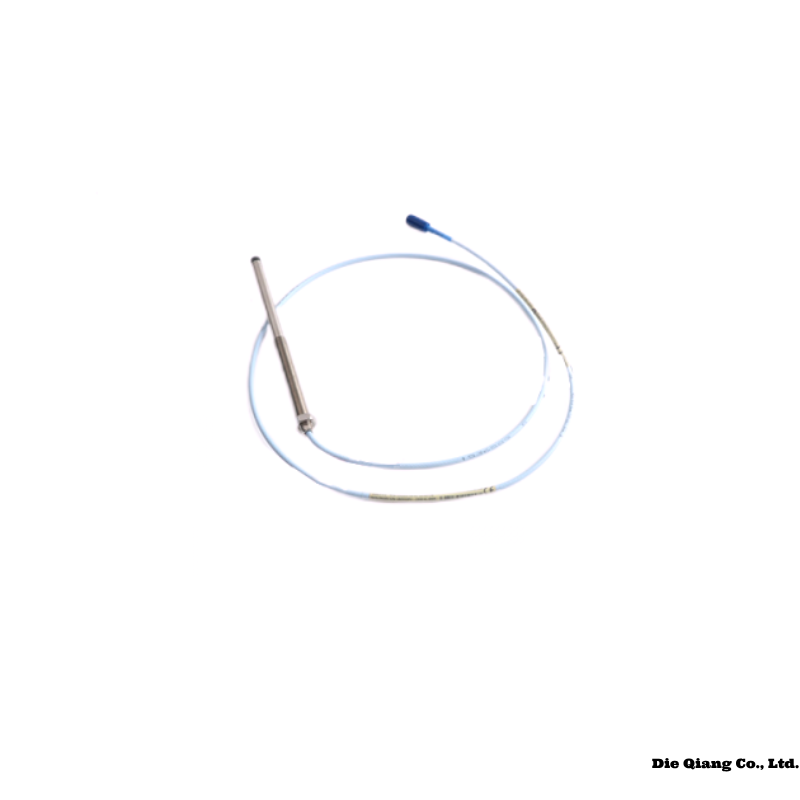

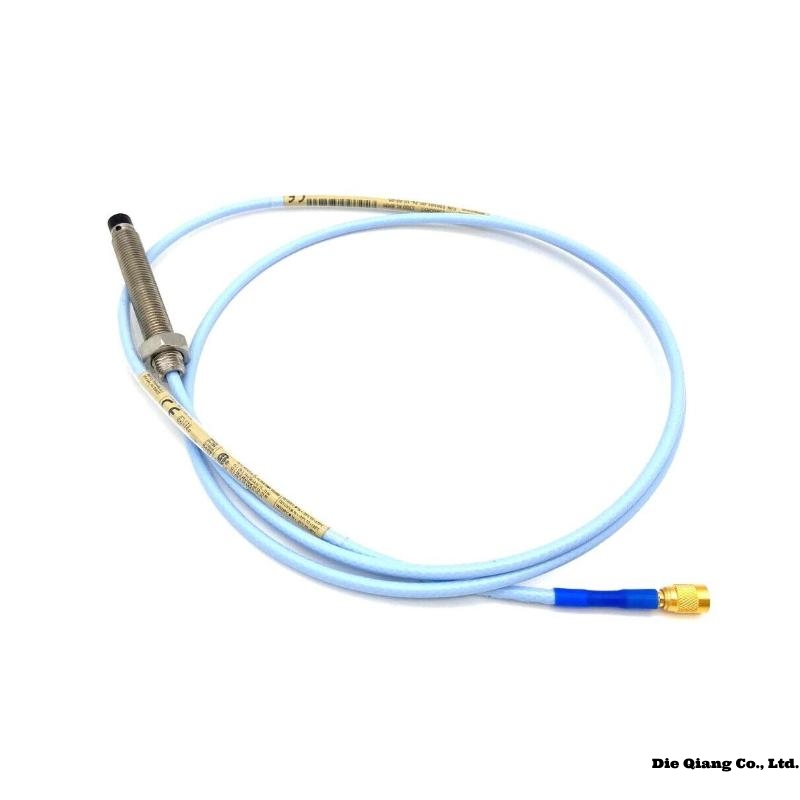

Bently Nevada 330101-00-12-10-02-05

Product Introduction

The Bently Nevada 330101-00-12-10-02-05 is a high-performance proximity probe assembly designed for industrial machinery monitoring. As part of the renowned 3300 XL Series by Bently Nevada, this proximity transducer system delivers unparalleled reliability and precise vibration measurements in rotating machinery. It consists of a probe, extension cable, and a matching proximitor sensor.

This specific model—330101-00-12-10-02-05—offers a probe length of 12 feet and utilizes a -24 Vdc power supply. It is engineered with Bently Nevada’s advanced XL technology, ensuring consistent performance even in harsh environments including extreme temperature, oil exposure, and electromagnetic interference.

The 3300 XL series is globally recognized for its durability and is widely adopted in industries such as power generation, petrochemical, oil & gas, and manufacturing, where machine health monitoring is vital for operational efficiency.

Product Advantages

-

High Accuracy and Reliability: Delivers accurate proximity measurements essential for precise vibration and displacement monitoring.

-

Harsh Environment Tolerance: Built to withstand oil, dust, and temperature extremes, enabling uninterrupted performance in aggressive industrial conditions.

-

XL Technology: Enhanced linearity and extended durability over traditional designs.

-

Non-Contact Sensing: Proximity-based monitoring allows real-time measurement without direct contact with the machinery.

-

Interchangeable Components: Probe, extension cable, and proximitor can be replaced or upgraded without full system replacement.

-

Global Compliance: Meets global industrial standards including CE and CSA, supporting universal deployment.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-00-12-10-02-05 |

| Series | 3300 XL |

| Probe diameter | 8mm |

| Cable Length | 1m |

| Connector Type | Miniature coaxial |

| Tip Diameter | 5 mm |

| Sensing Range | -2 mm to +2 mm |

| Power Supply | -24 Vdc (nominal) |

| Sensitivity | 7.87 mV/µm (200 mV/mil) |

| Operating Temperature | -35°C to +177°C |

| Frequency Response | 0 to 10 kHz |

| System Accuracy | ±0.127 mm (±5 mils) or better |

| Voltage Range | -18 Vdc to -27 Vdc |

| Weight | 0.323 kg |

| Compliance Certifications | CE, CSA, ATEX (select variants) |

| Mounting Thread | 3/8-24 UNF-2A |

Applications

The Bently Nevada 330101-00-12-10-02-05 is extensively utilized in high-demand environments that require robust machinery protection and precise monitoring. Key applications include:

-

Steam and Gas Turbines

-

Centrifugal Compressors

-

Electric Motors

-

Industrial Pumps

-

Gearboxes and Fans

-

Petrochemical Processing Equipment

-

Hydraulic Machines

Its non-contact proximity sensing ensures continuous monitoring of shaft position, vibration, and displacement—critical for predictive maintenance and safety compliance.

Compatible Models

The 330101-00-12-10-02-05 proximity probe is compatible with a variety of Bently Nevada proximity monitoring systems and components, including:

-

3300 XL Extension Cables (e.g., 330130-080-00-00)

-

3300 XL Proximitor Sensors (e.g., 330180-50-CN)

-

Monitoring Systems (e.g., 3500/42M, 3500/40M)

-

Machine Condition Monitoring Racks

-

Diagnostic and Portable Vibration Analyzers

It is backward-compatible with many earlier 3300 series transducer systems.

Installation Instructions

-

Mounting the Probe

Select a mounting location with a clear line of sight to the shaft or surface. Ensure the 3/8-24 UNF thread is clean and secure the probe into a threaded hole or bracket using a torque wrench (recommended torque: 3.5 Nm). -

Gap Adjustment

Set the initial gap between the probe tip and target surface to approximately 1 mm (40 mils). Fine-tune using the proximitor sensor’s voltage reading. -

Extension Cable Routing

Route the extension cable carefully, avoiding bends tighter than 25 mm radius. Use cable clamps where necessary and avoid electromagnetic sources. -

Proximitor Sensor Connection

Connect the extension cable to the matching proximitor sensor. Ensure correct polarity and secure connections. -

System Check and Calibration

Power up the system, check output signal stability, and calibrate the sensor using a calibration target or dial gauge if required.

6 Related Models

| Model Number | Probe Length | Cable Length | Tip Diameter | Voltage | Temperature Range |

|---|---|---|---|---|---|

| 330101-00-10-10-02-00 | 10 ft | 10 ft | 5 mm | -24 Vdc | -35°C to +177°C |

| 330101-00-08-10-02-00 | 8 ft | 10 ft | 5 mm | -24 Vdc | -35°C to +177°C |

| 330101-00-06-10-02-00 | 6 ft | 10 ft | 5 mm | -24 Vdc | -35°C to +177°C |

| 330101-00-05-10-02-00 | 5 ft | 10 ft | 5 mm | -24 Vdc | -35°C to +177°C |

| 330101-00-18-10-02-05 | 18 ft | 10 ft | 5 mm | -24 Vdc | -35°C to +177°C |

| 330101-00-24-10-02-05 | 24 ft | 10 ft | 5 mm | -24 Vdc | -35°C to +177°C |

8 Popular Bently Nevada Models

| Model Number | Description | Power Supply | Dimensions (mm) | Weight |

|---|---|---|---|---|

| 3500/42M | Dynamic Vibration Monitor | 18-36 Vdc | 241 × 24 × 185 | 450 g |

| 3500/22M | Transient Data Interface Module | 18-36 Vdc | 241 × 24 × 185 | 430 g |

| 3500/15 | Power Supply Module (AC) | 85–264 Vac | 241 × 24 × 185 | 480 g |

| 330103-00-12-10-02-00 | 3300 XL 8 mm Proximity Probe | -24 Vdc | 152 × 8 (probe body) | 170 g |

| 330180-51-05 | 3300 XL Proximitor Sensor | -24 Vdc | 90 × 60 × 30 | 250 g |

| 3500/40M | Proximitor Monitor Module | 18-36 Vdc | 241 × 24 × 185 | 460 g |

| 330130-085-00-00 | 3300 XL Extension Cable (8.5 m) | N/A | 8500 mm (length) | 220 g |

| 330500-02-00 | High Temperature Proximity Transducer System | -24 Vdc | Custom Configured | ~300 g |

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the Bently Nevada 330101-00-12-10-02-05?

A1: It is used to measure the proximity or displacement of rotating machinery shafts relative to their bearings, ensuring proper alignment and condition monitoring to prevent mechanical failures.

Q2: Can this probe be used in high-temperature environments?

A2: Yes, it is designed to operate in environments with temperatures ranging from -35°C to +177°C, making it suitable for turbines, compressors, and other heat-intensive machinery.

Q3: Is the probe compatible with the 3500 Series Monitoring Systems?

A3: Absolutely. The 330101-00-12-10-02-05 is fully compatible with Bently Nevada 3500 Series modules like 3500/40M and 3500/42M.

Q4: How should the gap voltage be calibrated during installation?

A4: The recommended initial gap is 1 mm (40 mils). Use a proximitor sensor to fine-tune the gap by adjusting the probe until the output voltage reads approximately -8 Vdc.

Q5: Can the cable or probe be replaced individually?

A5: Yes. Bently Nevada proximity systems are modular. You can independently replace the probe, extension cable, or proximitor sensor without needing to replace the entire system.

Q6: Is this model resistant to oil and vibration interference?

A6: Yes, the 3300 XL design includes advanced sealing and shielding to resist oil ingress and electromagnetic or vibration interference, ensuring accurate readings in harsh conditions.

Bently Nevada 330101-00-12-10-02-05 3300 XL 8 mm Proximity Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 8 mm Proximity Probe, 330101-00-12-10-02-05, Bently Nevada, Bently Nevada 330101-00-12-10-02-05