| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction:

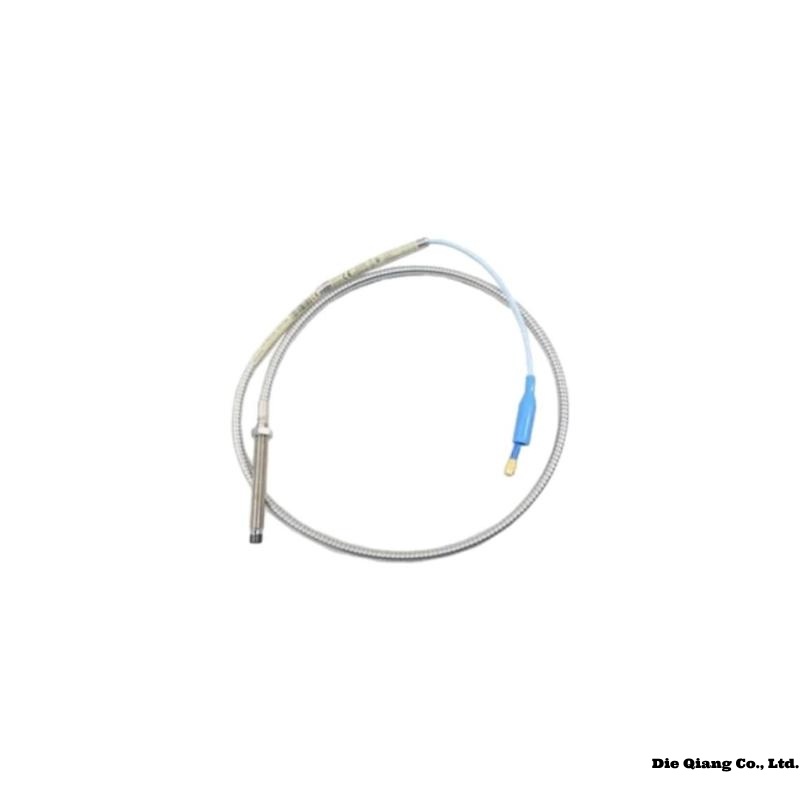

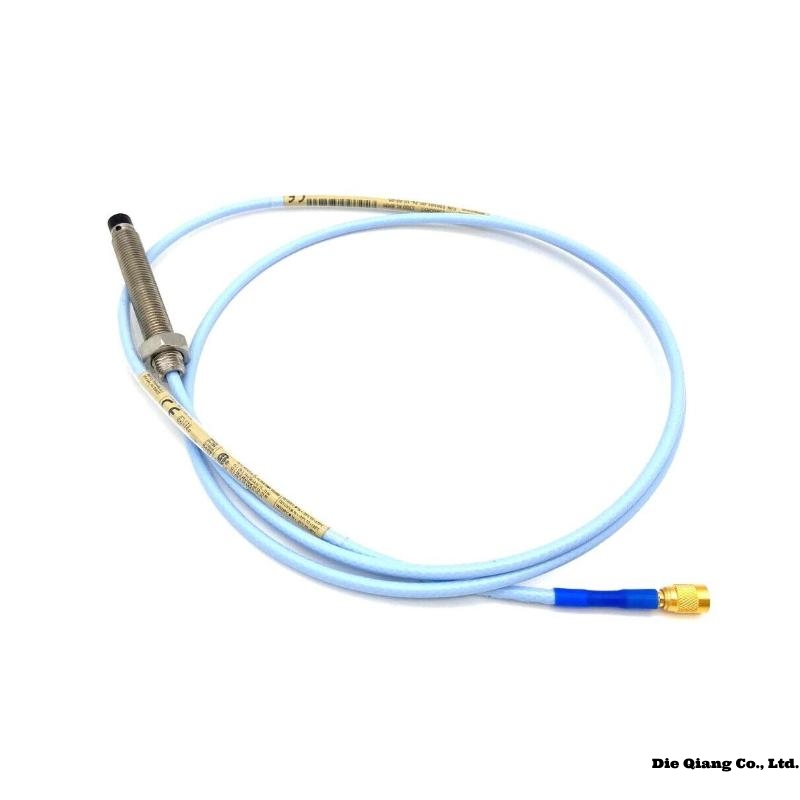

The Bently Nevada 330104-06-14-05-02-05 is a high-quality vibration sensor from the renowned Bently Nevada product line. It is designed to monitor and measure vibration levels in machinery such as turbines, motors, and generators. This sensor is an integral part of predictive maintenance systems, offering precise measurements and reliable data for condition monitoring. With its robust design, it can operate in harsh environments, ensuring durability and long service life.

Product Advantages:

-

Precision and Accuracy: Offers high accuracy in vibration measurement, providing detailed insights into equipment performance.

-

Durable and Reliable: Engineered to withstand harsh industrial environments, ensuring minimal downtime and reduced maintenance costs.

-

Easy Integration: Compatible with a wide range of Bently Nevada monitoring systems, ensuring smooth integration into existing setups.

-

Advanced Technology: Features advanced signal processing capabilities to provide real-time data for predictive maintenance.

-

Wide Operating Range: Capable of operating in various temperature ranges and environmental conditions, enhancing its versatility.

Technical Specifications:

| Specification | Details |

|---|---|

| Model Number | 330104-06-14-05-02-05 |

| Measurement Type | Vibration Sensor |

| Frequency Range | 10 Hz to 10 kHz |

| Sensitivity | 100 mV/g (typical) |

| Voltage | 24 V DC (typical) |

| Temperature Range | -40°C to +85°C |

| Weight | 0.7 kg |

| Dimensions (diameter) | 8 mm |

| Mounting Type | Threaded / Bolt-On |

| Output Signal | 4-20 mA |

| Housing Material | Stainless Steel |

Product Applications:

The Bently Nevada 330104-06-14-05-02-05 sensor is commonly used in the following applications:

-

Turbine Monitoring: Detects vibration anomalies in turbines, ensuring early detection of issues such as imbalance or misalignment.

-

Motor Health Monitoring: Used to monitor motor vibrations, helping to predict failures before they occur.

-

Pump Monitoring: Integrated into pump systems to monitor operational health and prevent unexpected downtime.

-

Gearbox Condition Monitoring: Ideal for tracking gearbox performance and detecting wear or faults.

-

Compressor Vibration Monitoring: Used to monitor compressors in a wide range of industries, such as oil & gas, petrochemical, and energy production.

Compatible Models:

Here are some recommended models from the Bently Nevada 3300 series or related products that work well with the 330104-06-14-05-02-05:

| Model Number | Description | Main Application |

|---|---|---|

| 330104-06-14-05-02-01 | Vibration sensor with similar specifications | Motor and turbine vibration monitoring |

| 330104-06-14-05-01-01 | High-sensitivity vibration sensor | Precision monitoring systems |

| 330500-04-00-04-01 | Integrated vibration sensor module | Broad machinery monitoring |

| 330702-02-02-03-01 | Wireless vibration sensor | Remote monitoring systems |

| 330180-06-04-04-01 | Vibration sensor for industrial equipment | General industrial use |

| 330700-03-01-01-01 | Condition monitoring system sensor | Performance optimization |

Recommended Bently Nevada Models:

These are 8 other popular models from Bently Nevada that you might find useful for various monitoring and maintenance tasks:

| Model Number | Description | Specifications |

|---|---|---|

| 350101-02-00-00 | Vibration Transducer | Output: 4-20 mA, Frequency range: 10 Hz to 1 kHz |

| 350701-02-00-00 | Vibration Monitoring Module | Output: 4-20 mA, Temperature range: -20°C to 70°C |

| 350210-02-01-00 | Velocity Transducer | Frequency range: 5 Hz to 10 kHz, Voltage: 24 V DC |

| 330105-02-05-01-00 | Accelerometer | Sensitivity: 10 mV/g, Weight: 0.6 kg |

| 330104-06-14-05-03-01 | Condition Monitoring Sensor | Output: 4-20 mA, Operating Temp: -40°C to +85°C |

| 350850-01-01-00 | Vibration Sensor for Generators | Frequency range: 10 Hz to 20 kHz, Voltage: 12 V DC |

| 350760-02-01-00 | Vibration Sensor for Motors | Sensitivity: 100 mV/g, Output: 4-20 mA |

| 350100-02-01-00 | Industrial Vibration Sensor | Weight: 0.5 kg, Frequency range: 5 Hz to 5 kHz |

Installation Instructions:

-

Location: Install the vibration sensor on a flat, stable surface of the machine. Ensure that the sensor is positioned near the bearing or part of the machine you wish to monitor.

-

Mounting: Secure the sensor using the threaded or bolt-on mounting options. Ensure the mounting is firm to avoid any sensor movement during operation.

-

Wiring: Connect the sensor’s output to the monitoring system using appropriate cables. Make sure that the connections are secure and meet the voltage specifications.

-

Calibration: After installation, calibrate the sensor to match the required sensitivity and operational parameters.

-

Testing: Run a test cycle to ensure the sensor is providing accurate readings and data to the monitoring system.

Frequently Asked Questions (FAQ):

Q1: What is the typical voltage for the 330104-06-14-05-02-05 vibration sensor?

A1: The typical voltage for this sensor is 24 V DC.

Q2: Can I use the 330104-06-14-05-02-05 sensor in outdoor environments?

A2: Yes, the sensor is designed to withstand harsh environmental conditions and can be used outdoors.

Q3: How do I mount the 330104-06-14-05-02-05 sensor?

A3: The sensor can be mounted using either threaded or bolt-on mounting options.

Q4: What is the sensitivity of the 330104-06-14-05-02-05 vibration sensor?

A4: The typical sensitivity is 100 mV/g.

Q5: What is the operating temperature range for this sensor?

A5: The sensor operates within a temperature range of -40°C to +85°C.

Q6: Can this sensor be used for real-time monitoring?

A6: Yes, it provides real-time vibration data that can be used for predictive maintenance and condition monitoring.

Bently Nevada 330104-06-14-05-02-05 3300 XL 8MM Sensor Cable

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||