| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

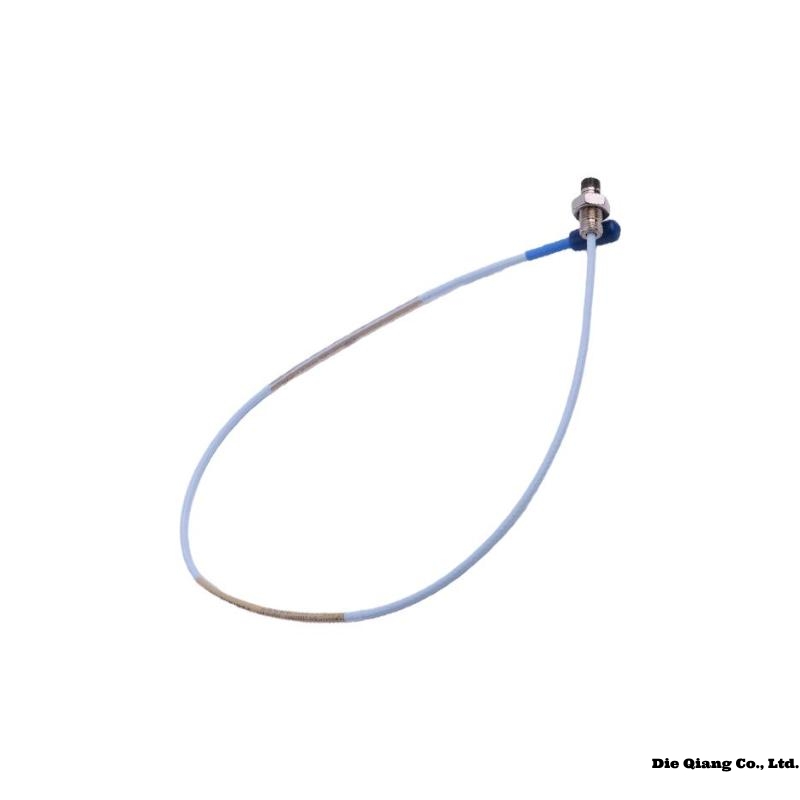

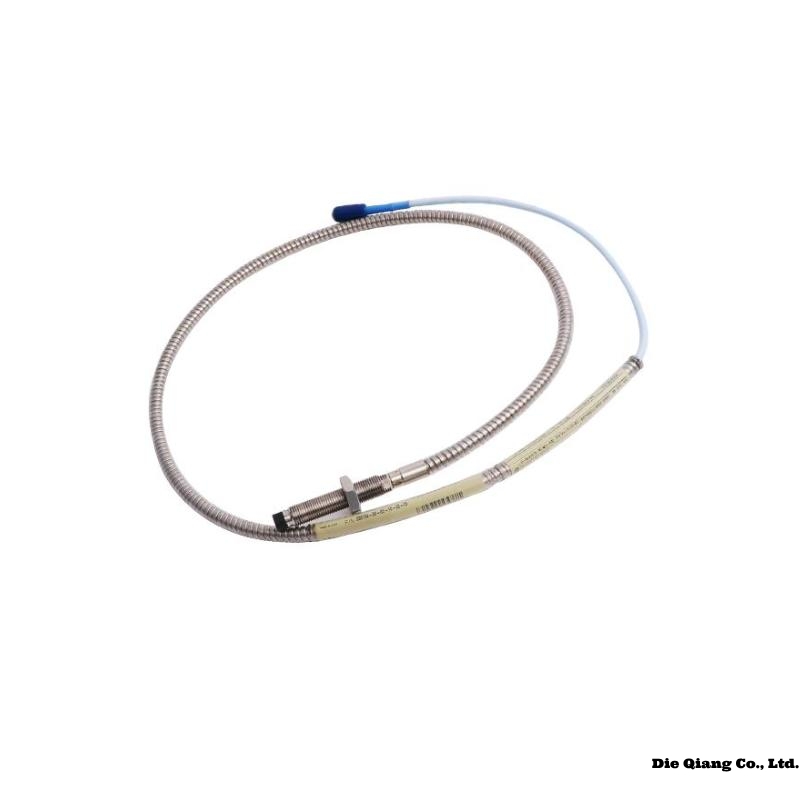

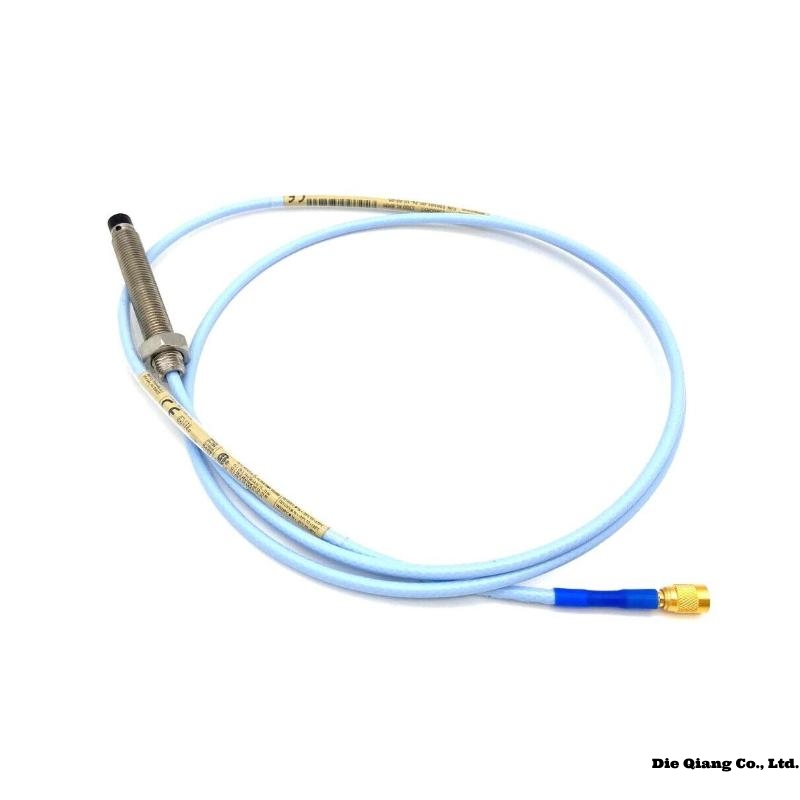

Bently Nevada 330104-10-16-10-02-00 Product Overview

The Bently Nevada 330104-10-16-10-02-00 is a high-performance vibration monitoring sensor from the 3300 XL 8mm Proximitor® Series. It is designed for precise measurement of shaft vibration, displacement, and position in industrial machinery, ensuring reliable condition monitoring and predictive maintenance.

This product is widely used in industries such as oil & gas, power generation, and manufacturing, where accurate vibration data is critical for preventing equipment failure and optimizing performance.

Product Advantages

- High Accuracy – Provides precise measurements for early fault detection.

- Robust Construction – Built to withstand harsh industrial environments.

- Wide Compatibility – Works seamlessly with Bently Nevada monitoring systems.

- Long Service Life – Durable materials ensure extended operational reliability.

- Easy Integration – Simple installation and configuration with existing systems.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330104-10-16-10-02-00 |

| Type | Proximity Probe (8mm) |

| Measurement Range | 0 to 2 mm (80 mils) |

| Frequency Response | 0.5 to 10 kHz |

| Output Signal | -2 to -18 VDC |

| Operating Voltage | 18 to 30 VDC |

| Temperature Range | -40°C to +120°C (-40°F to 248°F) |

| Probe diameter | 8mm |

| Weight | 0.7 kg |

| Cable Length | Standard 5m (customizable) |

Applications

- Turbines – Monitors shaft vibration in steam and gas turbines.

- Compressors – Detects misalignment and bearing wear.

- Pumps & Motors – Ensures smooth operation and prevents failures.

- Generators – Tracks rotor displacement and vibration.

- Industrial Gearboxes – Identifies gear mesh issues.

Compatible Models

The 330104-10-16-10-02-00 is typically used with:

- 3300 XL Proximitor® Transmitters

- 3500/42M Vibration Monitor

- 3300/16 Proximitor® Power Supply

- 3300/45 Proximitor® Seismic Monitor

Installation Instructions

- Mounting – Secure the probe at the recommended distance from the shaft (typically 1.0 to 1.5 mm).

- Wiring – Connect to a compatible Bently Nevada monitor using shielded cables.

- Calibration – Verify output signal using a gap simulator.

- Testing – Perform a dynamic run-up test to ensure proper operation.

- Documentation – Record installation details for future maintenance.

Recommended 6 Related Models

| Model Number | Description | Measurement Range | Voltage | Dimensions | Weight |

|---|---|---|---|---|---|

| 330104-00-00-10-02-00 | 5mm Proximity Probe | 0-1.25mm (50 mils) | 18-30 VDC | 5mm x 50mm | 0.08 kg |

| 330104-05-00-10-02-00 | 11mm Proximity Probe | 0-4mm (160 mils) | 18-30 VDC | 11mm x 75mm | 0.15 kg |

| 330104-20-00-10-02-00 | High-Temp Proximity Probe | 0-2mm (80 mils) | 18-30 VDC | 8mm x 60mm | 0.12 kg |

| 330104-30-00-10-02-00 | ATEX Certified Probe | 0-2mm (80 mils) | 18-30 VDC | 8mm x 60mm | 0.1 kg |

| 330104-40-00-10-02-00 | Submersible Probe | 0-2mm (80 mils) | 18-30 VDC | 8mm x 60mm | 0.1 kg |

| 330104-50-00-10-02-00 | Extended Cable Probe (10m) | 0-2mm (80 mils) | 18-30 VDC | 8mm x 60mm | 0.2 kg |

8 Popular Bently Nevada Models

| Model Number | Type | Key Feature | Voltage | Dimensions | Weight |

|---|---|---|---|---|---|

| 3500/42M | Vibration Monitor | 4-Channel Dynamic | 24 VDC | 160mm x 80mm | 1.2 kg |

| 3500/22M | Speed Monitor | Tachometer Input | 24 VDC | 160mm x 80mm | 1.1 kg |

| 3300/45 | Seismic Monitor | Accelerometer Input | 24 VDC | 160mm x 80mm | 1.0 kg |

| 3300/16 | Proximitor® Power Supply | Dual-Channel Output | 24 VDC | 120mm x 60mm | 0.8 kg |

| 3300/25 | Gap Voltage Monitor | Dual-Channel | 24 VDC | 120mm x 60mm | 0.7 kg |

| 3300/50 | Proximity Transmitter | 4-20mA Output | 24 VDC | 120mm x 60mm | 0.9 kg |

| 1900/65A | Accelerometer | High-Frequency | 18-30 VDC | 25mm x 25mm | 0.2 kg |

| 3500/92 | Communication Gateway | Modbus/OPC Support | 24 VDC | 200mm x 100mm | 1.5 kg |

FAQ (Frequently Asked Questions)

Q1: What is the recommended gap voltage for this probe?

A1: The optimal gap voltage is -10 VDC when installed at the recommended distance (1.0 to 1.5 mm).

Q2: Can this probe be used in hazardous areas?

A2: The standard model is not ATEX-certified. For hazardous environments, use 330104-30-00-10-02-00.

Q3: What is the maximum cable length supported?

A3: Up to 10 meters without signal degradation (longer lengths may require amplification).

Q4: How often should the probe be calibrated?

A4: Annual calibration is recommended for critical machinery.

Q5: Is this probe compatible with non-Bently Nevada systems?

A5: Yes, but optimal performance is achieved with Bently Nevada monitors.

Q6: What maintenance is required for this probe?

A6: Periodic inspection for physical damage and cable integrity is sufficient.

Bently Nevada 330104-10-16-10-02-00 Sensors

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||