| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

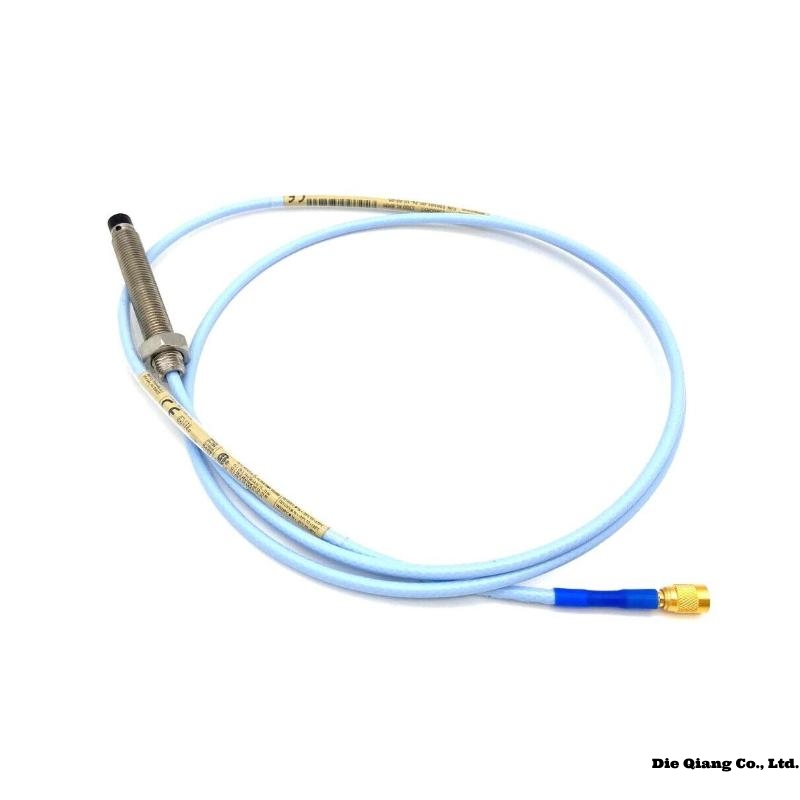

Bently Nevada 330104-14-19-10-11-00 Product Documentation

Product Description

The Bently Nevada 330104-14-19-10-11-00 is part of the renowned 3300 XL series, a proximity probe extension cable designed for high-precision machinery monitoring. Developed to meet the demanding requirements of industrial environments, this model is engineered to work seamlessly with Bently Nevada proximity probes and sensors. It ensures accurate measurement of shaft position and vibration in critical rotating equipment such as turbines, compressors, pumps, and motors.

This extension cable is designed with robust materials to provide excellent resistance against harsh industrial conditions, such as high temperatures, humidity, oil mist, and electromagnetic interference. With superior signal integrity, it delivers reliable data transmission over long distances, making it ideal for remote monitoring setups.

The Bently Nevada 330104-14-19-10-11-00 integrates smoothly into existing monitoring systems and supports a variety of critical condition monitoring and machinery protection applications.

Product Advantages

-

High Signal Integrity: Maintains precise data transmission with minimal signal loss over extended cable lengths.

-

Robust Construction: Durable jacket and shielding ensure protection against mechanical stress, oil, moisture, and electrical interference.

-

Wide Compatibility: Fully compatible with the Bently Nevada 3300 XL series transducers and monitors.

-

Ease of Installation: Designed for straightforward setup, minimizing downtime during installation and maintenance.

-

Reliable Performance in Harsh Environments: Functions effectively in high-temperature, high-vibration, and hazardous industrial areas.

-

Enhanced Equipment Protection: Helps prevent unplanned downtime by enabling early detection of mechanical anomalies.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330104-14-19-10-11-00 |

| Series | 3300 XL |

| Probe diameter | 8 mm |

| Connector Type | ClickLoc™ Connectors |

| Outer Jacket Material | FEP (Fluorinated Ethylene Propylene) |

| Weight | 0.7 kg |

| Voltage Rating | ≤ 30 VDC (Signal) |

| Operating Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Bend Radius | ≥ 25.4 mm (1.0 inch) |

| Resistance | ≤ 0.28 ohms/meter |

| Capacitance | ≤ 76 pF/meter |

| Vibration Rating | 10 g, 10–2000 Hz |

| Humidity Resistance | Up to 95% non-condensing |

| Certifications | CE, CSA, ATEX, IECEx |

Applications

-

Steam and Gas Turbines: Monitor shaft displacement and vibration to ensure optimal performance and avoid catastrophic failures.

-

Compressors: Detect early signs of mechanical wear, imbalance, or misalignment.

-

Industrial Pumps: Prevent cavitation and bearing failures by continuous vibration monitoring.

-

Electric Motors: Monitor rotor position and vibrations to prolong motor life.

-

Gearboxes: Ensure the reliability of gear-driven machinery with continuous condition monitoring.

-

Fans and Blowers: Detect imbalance and vibration issues in HVAC and industrial fans.

Compatible Models

-

Bently Nevada 330130-080-00-00 Proximity Probe Cable

-

Bently Nevada 330101-00-36-10-02-00 Proximity Probe

-

Bently Nevada 330180-51-05 Proximitor Sensor

-

Bently Nevada 330103-00-05-10-02-00 Extension Cable

-

Bently Nevada 330105-02-12 Proximitor Sensor

-

Bently Nevada 3300 XL 8 mm Proximity Probe System

Installation Guide

-

Preparation:

-

Ensure that the system power is turned off before installation.

-

Verify that all components, including the probe, cable, and Proximitor sensor, are compatible and undamaged.

-

-

Cable Routing:

-

Route the extension cable carefully to avoid sharp bends and potential mechanical damage.

-

Maintain the minimum bend radius of 25.4 mm to ensure signal integrity.

-

-

Connection:

-

Connect the probe end to the corresponding sensor using the ClickLoc™ connector.

-

Secure the connection tightly to prevent loosening due to vibration.

-

-

System Integration:

-

Connect the extension cable to the monitoring system as per the wiring diagram provided in the system manual.

-

Use proper grounding to reduce electromagnetic interference.

-

-

Testing:

-

After installation, power up the system and perform calibration to ensure accurate readings.

-

Check for signal stability and data accuracy.

-

-

Maintenance:

-

Periodically inspect the cable for wear and tear.

-

Replace the cable if signs of insulation damage or connector degradation appear.

-

Related Models (Same Series or Similar Function)

| Model Number | Description | Cable Length | Voltage Rating | Weight |

|---|---|---|---|---|

| 330104-00-05-10-02-00 | Extension cable for proximity system | 5 ft | ≤ 30 VDC | ~0.4 kg |

| 330104-00-10-10-02-00 | Extension cable for high-temperature areas | 10 ft | ≤ 30 VDC | ~0.6 kg |

| 330104-00-15-10-02-00 | Extended length extension cable | 15 ft | ≤ 30 VDC | ~1.1 kg |

| 330103-00-05-10-02-00 | Rugged extension cable | 5 ft | ≤ 30 VDC | ~0.4 kg |

| 330130-040-00-00 | Proximity probe extension cable | 40 ft | ≤ 30 VDC | ~2.5 kg |

| 330105-02-12 | Proximitor sensor compatible with 330104 | N/A | ≤ 30 VDC | ~0.7 kg |

Popular Models from the Same Brand (Bently Nevada)

| Model Number | Description | Application Area | Voltage Rating | Weight |

|---|---|---|---|---|

| 3300 XL 8mm Proximity Probe | Shaft position and vibration monitoring probe | General machinery | ≤ 30 VDC | ~0.3 kg |

| 3500/22M | Transient Data Interface Module | Condition monitoring | 24 VDC | ~1.2 kg |

| 3500/42M | Proximitor Seismic Monitor Module | Vibration monitoring | 24 VDC | ~0.9 kg |

| 3500/25 | Keyphasor Module | Rotational speed sensing | 24 VDC | ~0.8 kg |

| 330180-91-05 | Proximitor Sensor | Vibration measurement | ≤ 30 VDC | ~0.75 kg |

| 330103-00-05-10-02-00 | Extension Cable | Industrial monitoring | ≤ 30 VDC | ~0.4 kg |

| 330130-040-00-00 | Long-length Extension Cable | Extended installations | ≤ 30 VDC | ~2.5 kg |

| 3701/40 | Machinery Protection System | Critical equipment safety | 24 VDC | ~3.5 kg |

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the Bently Nevada 330104-14-19-10-11-00?

A1: This cable is designed to extend the connection between a proximity probe and the monitoring system, ensuring accurate signal transmission over longer distances in industrial environments.

Q2: Can this cable be used in high-temperature environments?

A2: Yes, the cable is rated for temperatures up to +177°C (+350°F), making it suitable for high-temperature industrial applications.

Q3: How do I ensure optimal performance during installation?

A3: Avoid sharp bends, ensure proper grounding, secure all connections firmly, and maintain the recommended bend radius to preserve signal integrity.

Q4: Is this cable compatible with older Bently Nevada systems?

A4: Yes, the 330104-14-19-10-11-00 is fully compatible with legacy Bently Nevada 3300 XL series systems, as well as newer monitoring equipment.

Q5: How often should the cable be inspected for maintenance?

A5: It is recommended to visually inspect the cable during routine equipment maintenance or at least once every six months, especially in harsh environments.

Q6: What certifications does this cable have for industrial use?

A6: The cable is certified under CE, CSA, ATEX, and IECEx standards, ensuring safe use in hazardous industrial locations.

Bently Nevada 330104-14-19-10-11-00 3300 XL 8 mm Reverse Mount Probes

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 8 mm Reverse Mount Probes, 330104-14-19-10-11-00, Bently Nevada, Bently Nevada 330104-14-19-10-11-00