| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

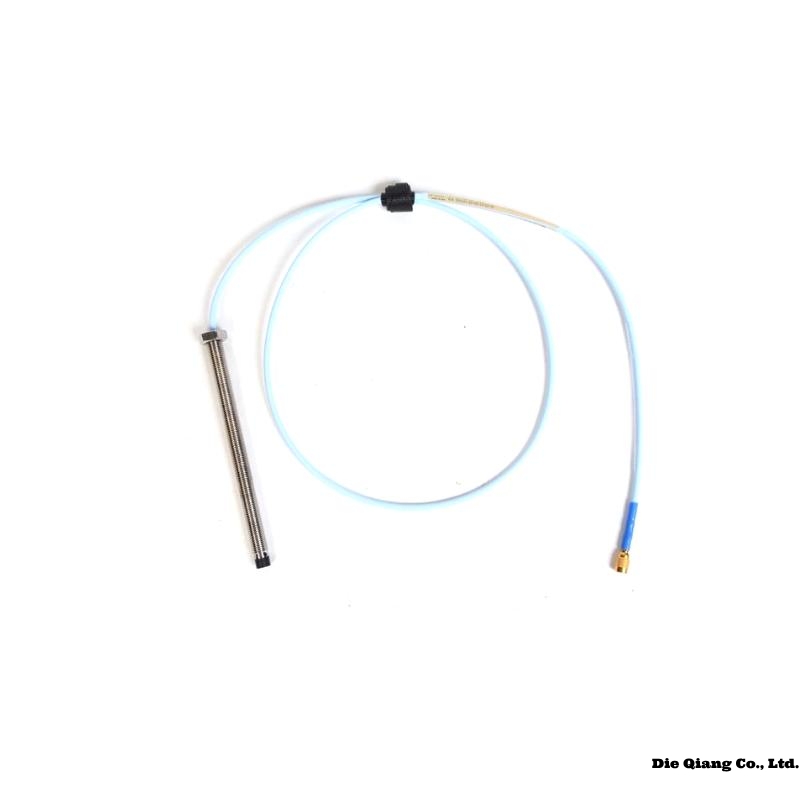

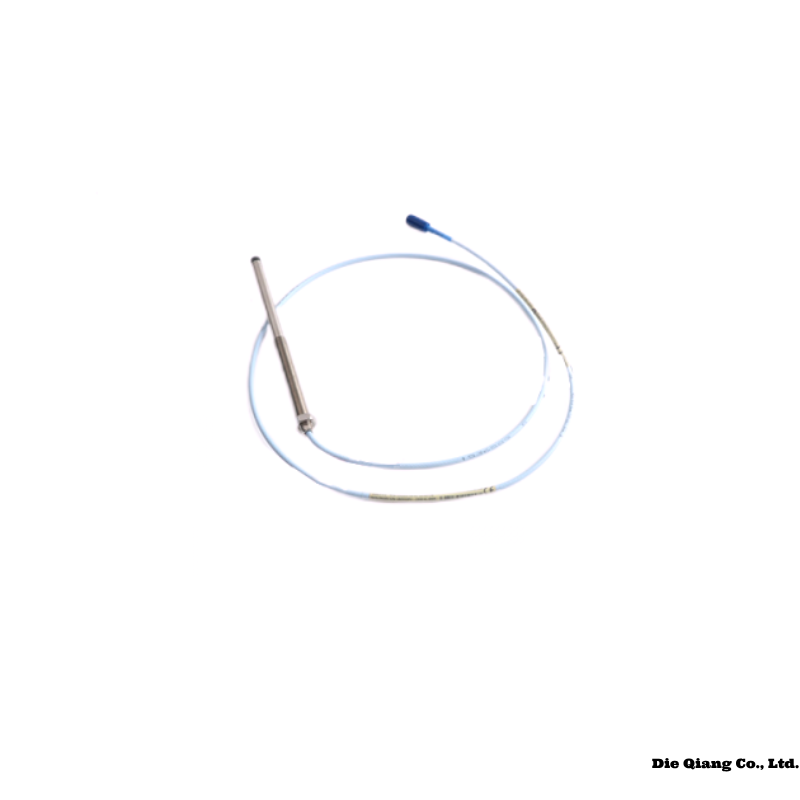

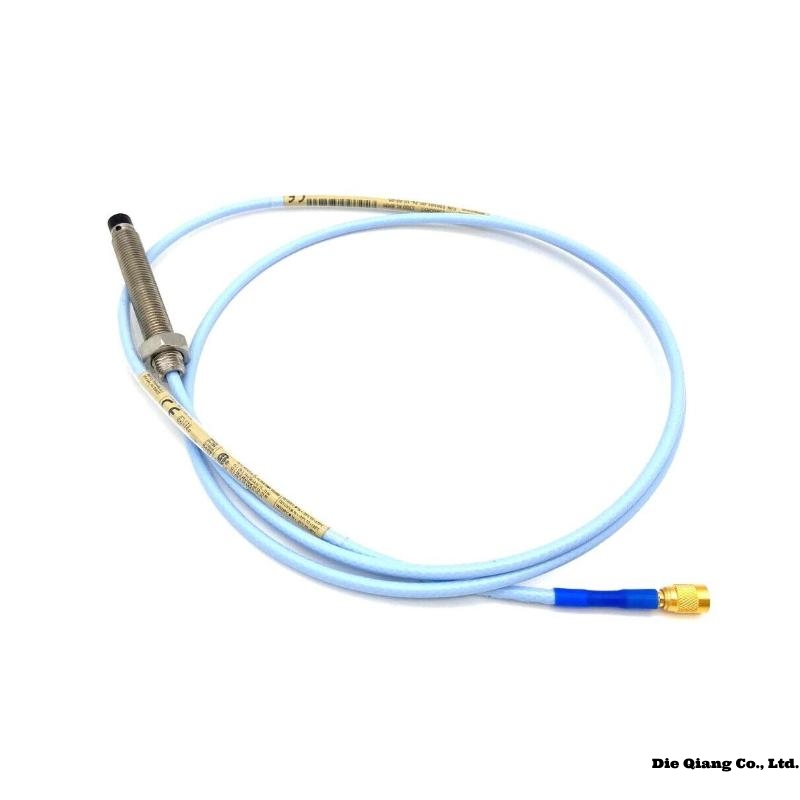

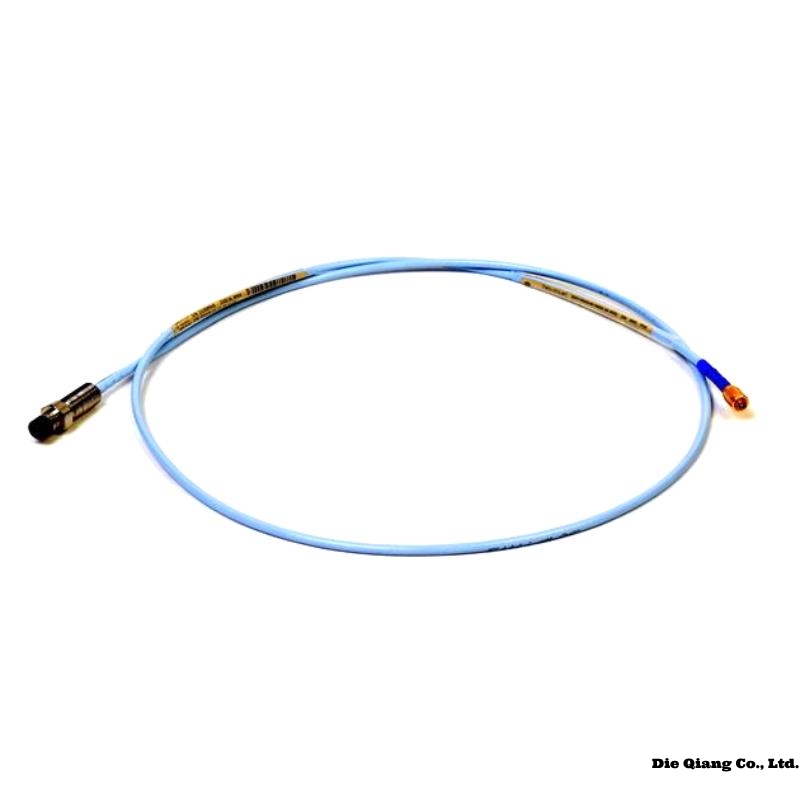

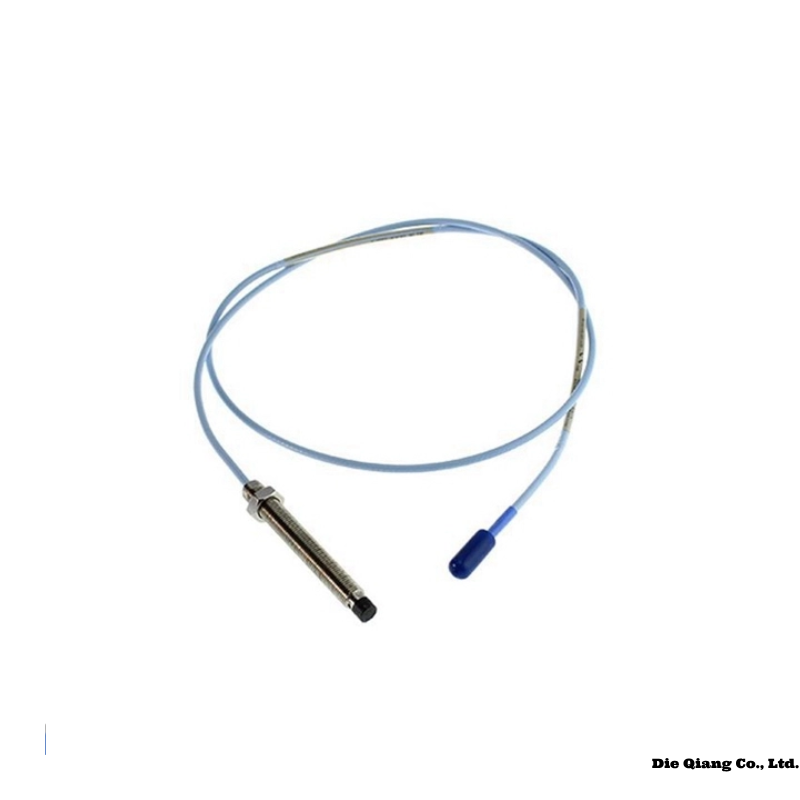

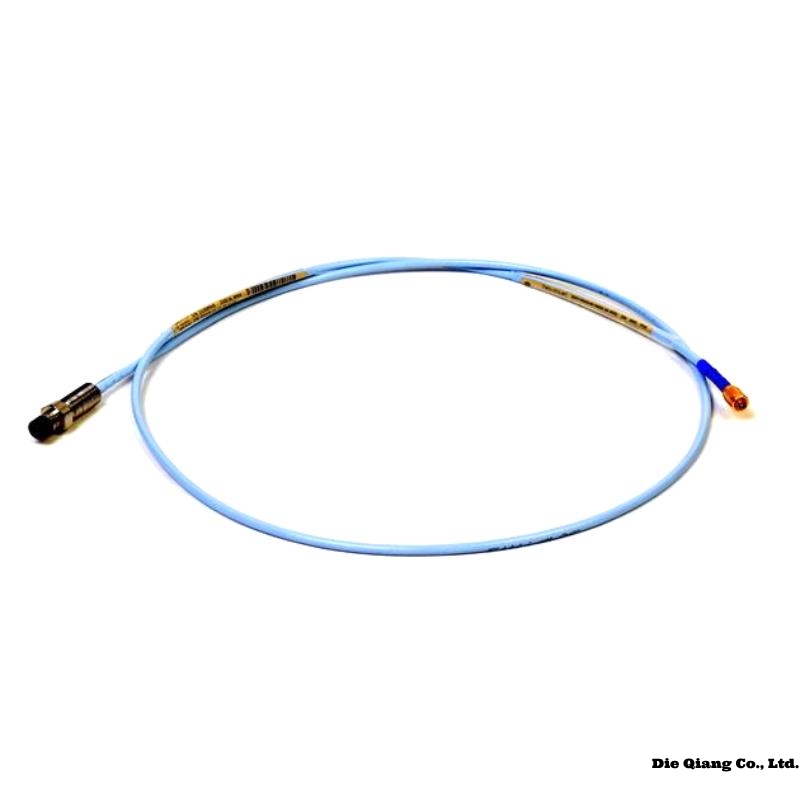

Bently Nevada 330105-02-12-05-02-01 Product Overview

The Bently Nevada 330105-02-12-05-02-01 is a high-performance vibration monitoring transducer designed for industrial machinery protection and condition monitoring. It is part of the Bently Nevada 3300 series, renowned for its reliability and precision in critical applications.

This transducer is commonly used in industries such as oil & gas, power generation, and manufacturing to detect vibration and provide real-time data for predictive maintenance.

Product Advantages

- High Accuracy: Delivers precise vibration measurements for early fault detection.

- Robust Construction: Built to withstand harsh industrial environments, including extreme temperatures and corrosive conditions.

- Easy Integration: Compatible with Bently Nevada monitoring systems for seamless data acquisition.

- Long Service Life: Designed for durability with minimal maintenance requirements.

- Wide Compatibility: Works with various machinery types, including turbines, compressors, and pumps.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330105-02-12-05-02-01 |

| Cable length | 0.5 m |

| Weight | 0.7 kg |

| Operating Voltage | 18 – 30 VDC |

| Output Signal | 4 – 20 mA (loop-powered) |

| Frequency Range | 10 Hz – 1 kHz |

| Temperature Range | -40°C to +85°C |

| Protection Rating | IP67 |

| Mounting | Stud or adhesive mounting |

Applications

- Turbine Monitoring: Detects blade pass frequency and rotor imbalances.

- Compressor Vibration Analysis: Identifies misalignment and bearing wear.

- Pump Condition Monitoring: Tracks cavitation and mechanical looseness.

- Electric Motor Diagnostics: Monitors vibration due to electrical or mechanical faults.

Compatible Models for System Integration

- 3300/20 Proximitor (for displacement measurement)

- 3300/25 Accelerometer (for high-frequency vibration)

- 3300/40 Seismic Transducer (for low-frequency applications)

- 3300/50 Phasor Module (for phase analysis)

- 3300/16 Power Supply Module (for system power management)

- 3300/90 Display Module (for real-time data visualization)

Installation Instructions

- Mounting: Secure the transducer using the provided stud or adhesive. Ensure proper alignment with the machine surface.

- Wiring: Connect the power supply (18-30 VDC) and output signal (4-20 mA) to the monitoring system.

- Calibration: Verify the signal output using a calibrated vibration source.

- Testing: Perform a functional test to ensure accurate readings before full operation.

Recommended Related Models (Same Series)

| Model | Description | Dimensions | Weight | Voltage |

|---|---|---|---|---|

| 330105-01-12-05-02-01 | Vibration Transducer (Low Range) | 50x80x30 mm | 0.5 kg | 18-30 VDC |

| 330105-03-12-05-02-01 | Vibration Transducer (High Range) | 50x80x30 mm | 0.5 kg | 18-30 VDC |

| 330106-02-12-05-02-01 | Temperature Compensated Version | 55x85x35 mm | 0.6 kg | 18-30 VDC |

| 330107-02-12-05-02-01 | Explosion-Proof Variant | 60x90x40 mm | 0.8 kg | 18-30 VDC |

| 330108-02-12-05-02-01 | High-Temperature Version | 50x80x30 mm | 0.5 kg | 18-30 VDC |

| 330109-02-12-05-02-01 | Wireless Vibration Transducer | 50x80x30 mm | 0.5 kg | 18-30 VDC |

Top 8 Popular Bently Nevada Models

| Model | Type | Dimensions | Weight | Voltage | Key Feature |

|---|---|---|---|---|---|

| 3500/42M | Vibration Monitor | 150x100x50 mm | 1.2 kg | 24 VDC | Multi-channel |

| 1900/65A | Proximity Probe | 10×50 mm | 0.1 kg | -18 to -24 VDC | High sensitivity |

| 3300/25-01-00 | Accelerometer | 30×60 mm | 0.3 kg | 18-30 VDC | Wide frequency range |

| 3500/22-01-00 | Tachometer Module | 120x80x40 mm | 0.9 kg | 24 VDC | Speed monitoring |

| 3300/16-02-00 | Power Supply | 100x70x30 mm | 0.7 kg | 90-240 VAC | System power |

| 3500/92-01-00 | Communication Gateway | 200x150x60 mm | 2.0 kg | 24 VDC | Data integration |

| 3300/XL 8mm | Proximity Sensor | 8×50 mm | 0.1 kg | -18 to -24 VDC | Miniature design |

| 3500/15-02-00 | Relay Module | 120x80x40 mm | 0.8 kg | 24 VDC | Alarm triggering |

Frequently Asked Questions (FAQ)

Q1: What is the operating temperature range of the 330105-02-12-05-02-01?

A1: The transducer operates between -40°C to +85°C.

Q2: Can this transducer be used in hazardous areas?

A2: No, for explosive environments, consider the 330107-02-12-05-02-01 (explosion-proof variant).

Q3: What is the output signal type?

A3: It provides a 4-20 mA loop-powered output.

Q4: How should the transducer be mounted for optimal performance?

A4: Use either stud mounting or industrial adhesive, ensuring direct contact with the machine surface.

Q5: Is calibration required after installation?

A5: Yes, calibration using a known vibration source is recommended.

Q6: What is the IP rating of this model?

A6: It has an IP67 rating, making it dust-tight and waterproof for temporary immersion.

Bently Nevada 330105-02-12-05-02-01 reverse mount proximity probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

330105-02-12-05-02-01, Bently Nevada, Bently Nevada 330105-02-12-05-02-01, reverse mount proximity probe