| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

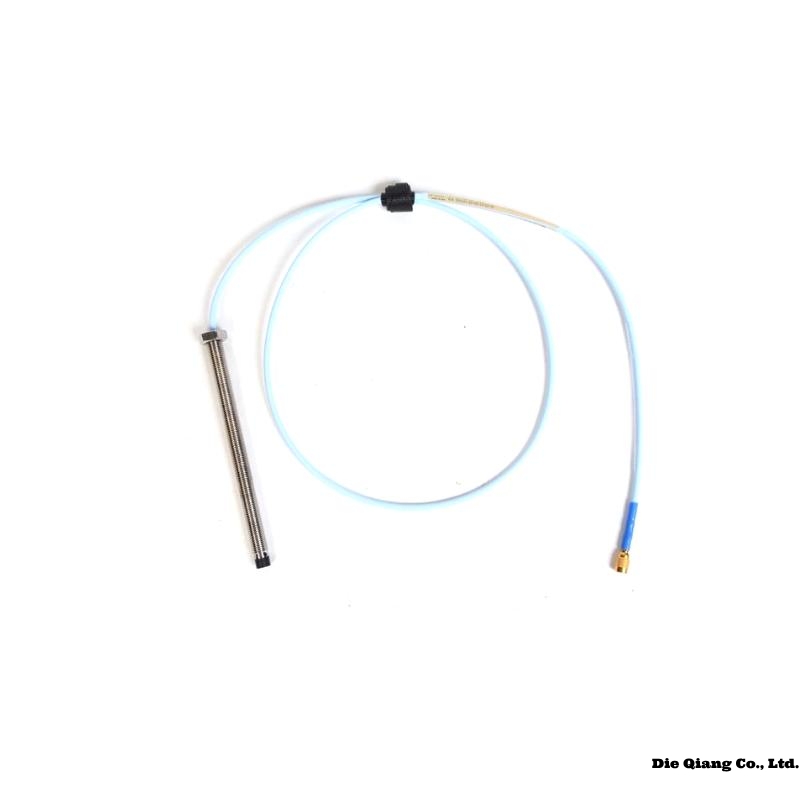

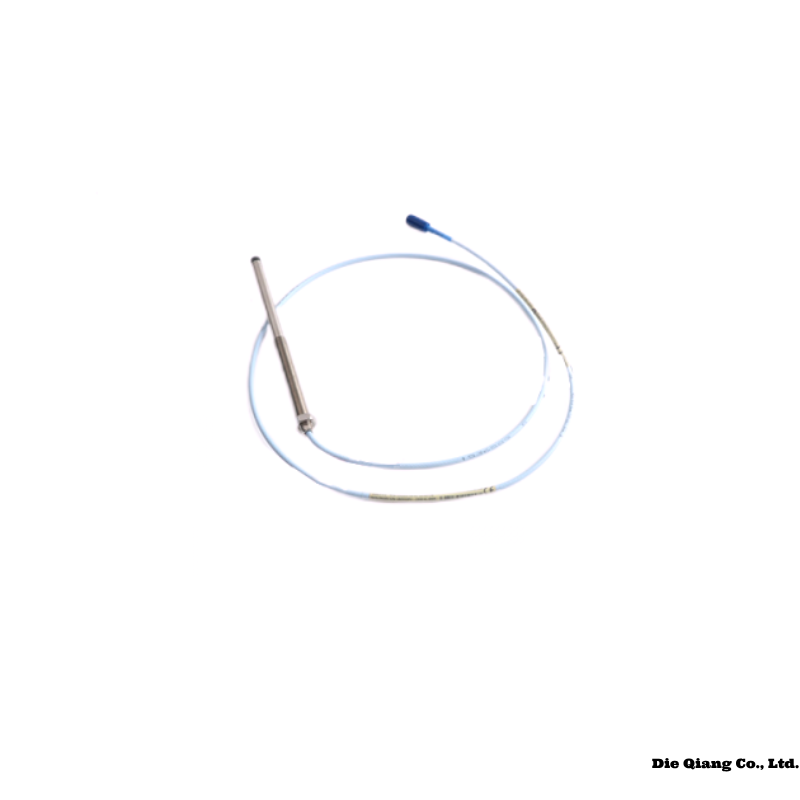

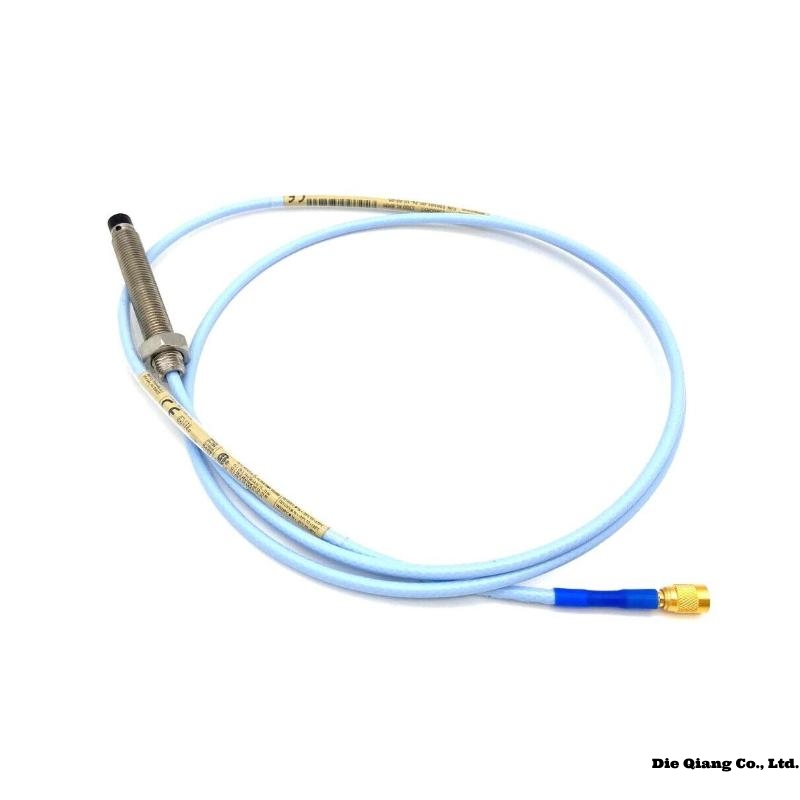

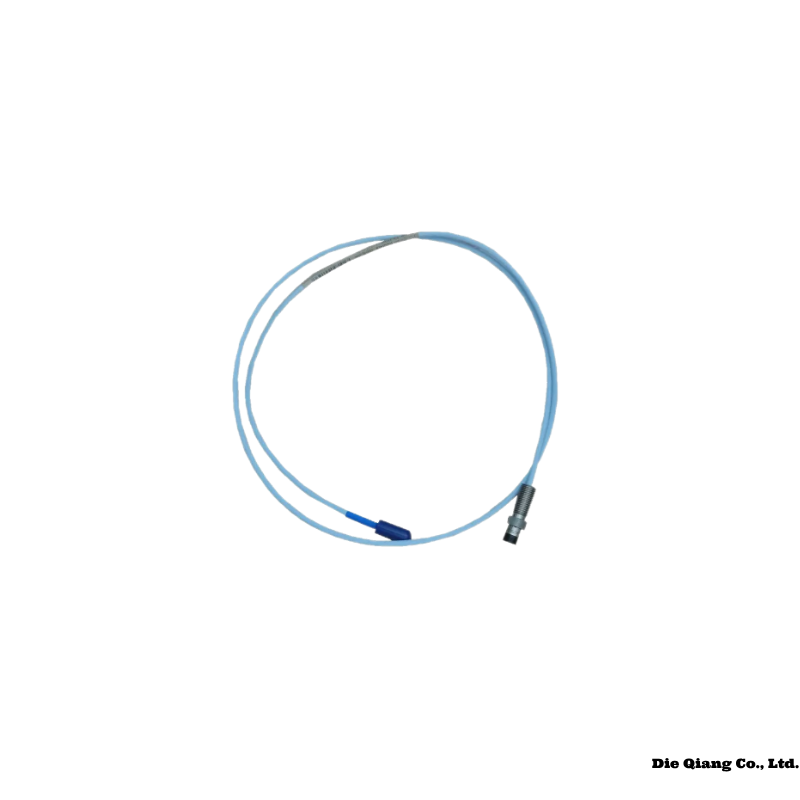

Bently Nevada 330105-02-12-10-02-00 Product Overview

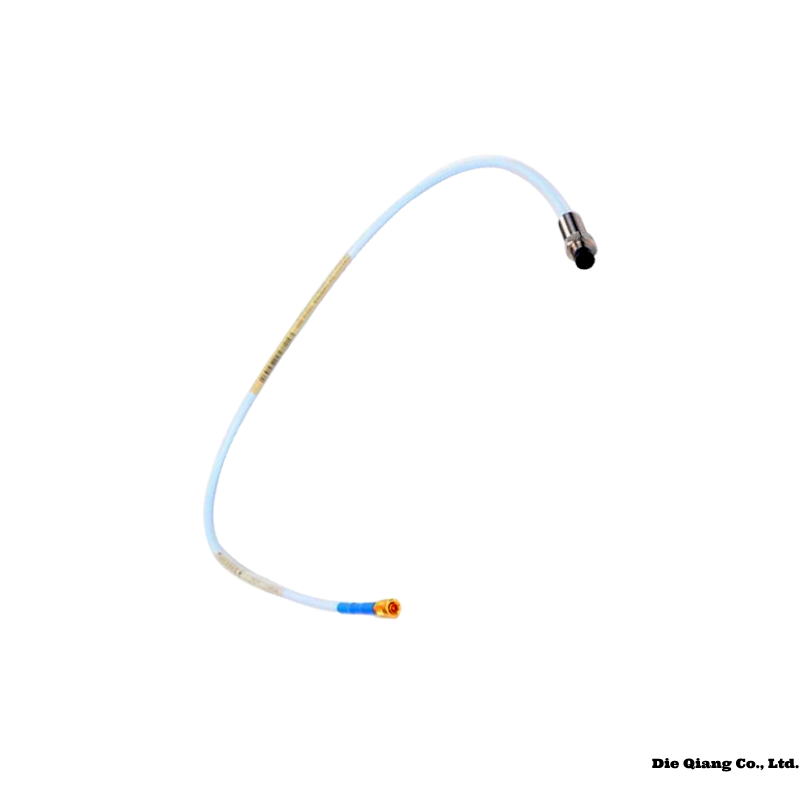

The Bently Nevada 330105-02-12-10-02-00 is a high-performance vibration monitoring sensor from the 3300 XL 8mm Proximitor® Series. Designed for precision measurement of radial vibration and axial position in rotating machinery, this sensor is widely used in industrial applications to ensure equipment reliability and prevent failures.

Product Advantages

- High Accuracy: Provides precise measurement of vibration and displacement, ensuring early fault detection.

- Robust Construction: Built to withstand harsh industrial environments, including high temperatures and EMI interference.

- Wide Compatibility: Works seamlessly with Bently Nevada monitoring systems.

- Long Service Life: Durable materials and advanced engineering ensure extended operational life.

- Easy Integration: Simple installation and compatibility with existing monitoring setups.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | 330105-02-12-10-02-00 |

| Type | Proximity Probe (8mm) |

| Operating Voltage | -18 to -26 VDC |

| Output Signal | -2 to -18 VDC (Linear) |

| Frequency Response | 0.5 to 12 kHz |

| Temperature Range | -40°C to +120°C (-40°F to 248°F) |

| Dimensions | 8mm diameter |

| Weight | 0.7 kg |

| Cable Length | 1m |

| Compliance | ISO 10816, API 670 |

Applications

- Turbines & Compressors: Monitors vibration in gas and steam turbines.

- Pumps & Motors: Detects misalignment and bearing wear.

- Generators: Ensures stable operation by tracking rotor displacement.

- Oil & Gas: Used in critical machinery for predictive maintenance.

- Power Plants: Enhances reliability in high-speed rotating equipment.

Compatible Models

The 330105-02-12-10-02-00 is typically used with:

- 3300 XL Proximitor® Transducer

- 3300 XL 8mm Extension Cable

- 3300 Monitor (e.g., 3300/20, 3300/25)

- 3500/22M Vibration Monitor

Installation Instructions

- Mounting: Secure the probe using the provided bracket, ensuring proper alignment with the target shaft.

- Gap Adjustment: Set the gap voltage to -10 VDC (±0.5 V) for optimal performance.

- Wiring: Connect the probe to the monitoring system using shielded cables to reduce noise.

- Calibration: Verify output signals using a calibration tool before final operation.

- Testing: Perform a run-up test to confirm signal stability.

Recommended Related Models (Same Series)

| Model | Type | Voltage | Dimensions | Weight | Key Feature |

|---|---|---|---|---|---|

| 330104-02-12-10-02-00 | 5mm Proximity Probe | -18 to -26V | 5mm x 50mm | 120g | Compact design |

| 330106-02-12-10-02-00 | 11mm Proximity Probe | -18 to -26V | 11mm x 70mm | 200g | Heavy-duty applications |

| 3300/45-01-00 | Proximitor® Transducer | +24V DC | 90mm x 60mm | 300g | Signal conditioning |

| 3300/20-02-00 | Monitor Module | 120/240V AC | 150mm x 80mm | 1.2kg | 4-channel vibration |

| 330701-000-065-10-02 | Accelerometer | 18-30V DC | 25mm x 25mm | 100g | High-frequency sensing |

| 330180-90-00 | Extension Cable | N/A | 10m length | 500g | EMI-resistant shielding |

Top 8 Popular Bently Nevada Models

| Model | Type | Voltage | Dimensions | Weight | Key Feature |

|---|---|---|---|---|---|

| 3500/42M | Vibration Monitor | 24V DC | 200mm x 100mm | 2.5kg | 16-channel system |

| 1900/65A | Speed Sensor | 10-30V DC | 30mm x 60mm | 250g | High-accuracy RPM |

| 3300/16-14-01 | Proximity Sensor | -18 to -26V | 8mm x 60mm | 150g | Turbo machinery |

| 3500/22M | Vibration Monitor | 120V AC | 150mm x 80mm | 1.8kg | Dual-channel analysis |

| 3300/25-01-00 | Monitor Module | 24V DC | 100mm x 60mm | 800g | Temperature monitoring |

| 330701-000-050 | Accelerometer | 18-30V DC | 20mm x 20mm | 80g | Low-frequency vibration |

| 3500/92 | Communication Gateway | 24V DC | 120mm x 80mm | 1kg | Ethernet connectivity |

| 3300/45-02-00 | Proximitor® | -18 to -26V | 90mm x 60mm | 300g | Signal amplification |

FAQ (Frequently Asked Questions)

Q1: What is the operating temperature range of the 330105-02-12-10-02-00?

A1: It operates between -40°C to +120°C (-40°F to 248°F).

Q2: Can this probe be used in hazardous environments?

A2: Yes, but an additional explosion-proof enclosure may be required for certified hazardous areas.

Q3: What is the recommended gap voltage for installation?

A3: The optimal gap voltage is -10 VDC (±0.5 V).

Q4: Is the cable length customizable?

A4: Yes, cables can be ordered in 1m to 10m lengths based on application needs.

Q5: How often should the probe be calibrated?

A5: Calibration should be performed annually or during major maintenance shutdowns.

Q6: Can this sensor measure both vibration and position?

A6: Yes, it measures radial vibration and axial position simultaneously.

Bently Nevada 330105-02-12-10-02-00 3300 XL 8 mm Reverse Mount Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

3300 XL 8 mm Reverse Mount Probe, 330105-02-12-10-02-00, Bently Nevada, Bently Nevada 330105-02-12-10-02-00