| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

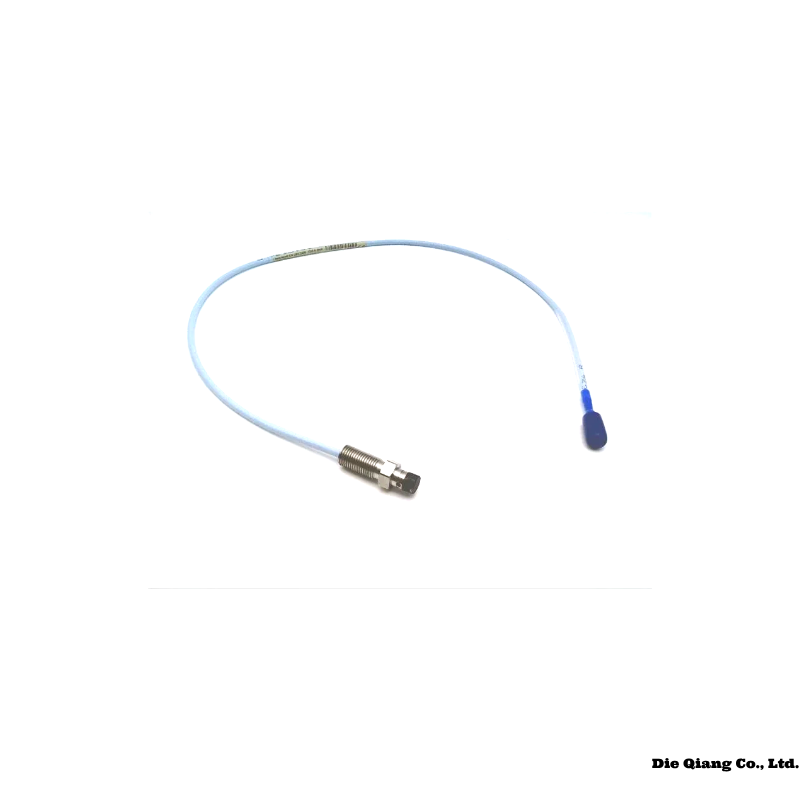

Bently Nevada 330105-02-12 Product Documentation

Product Description

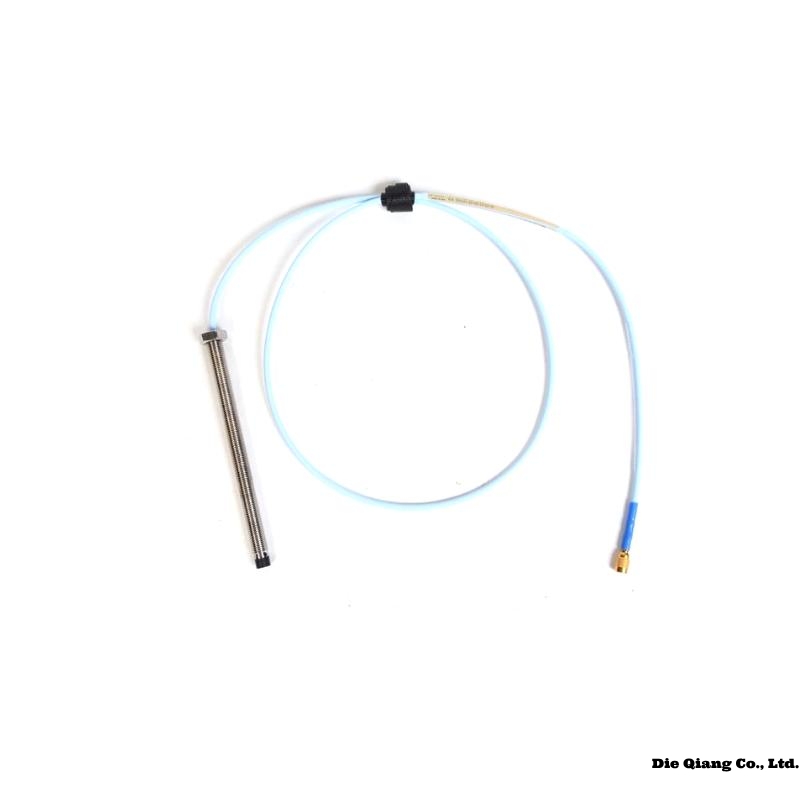

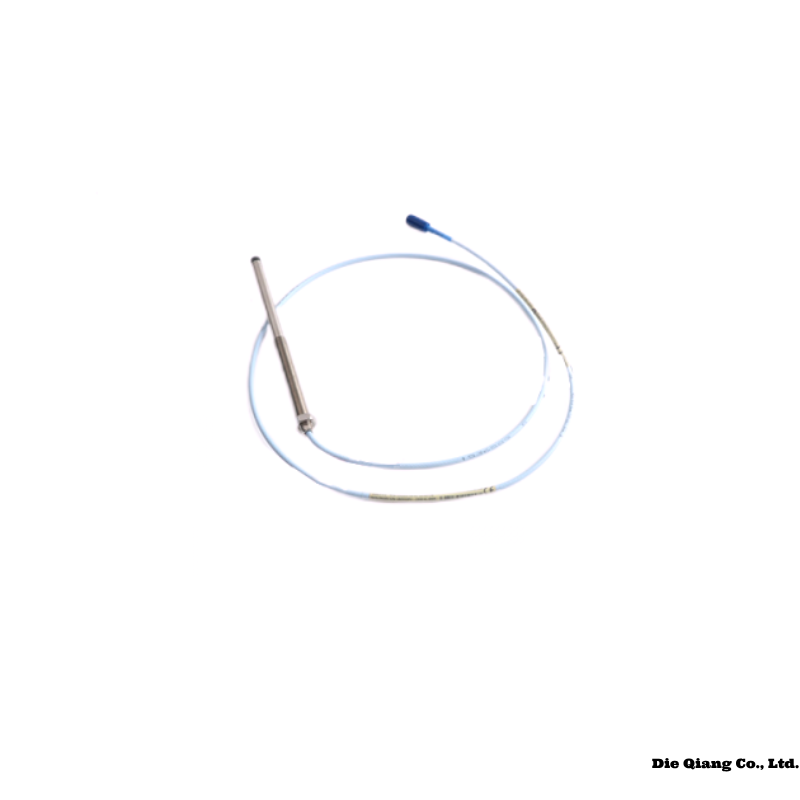

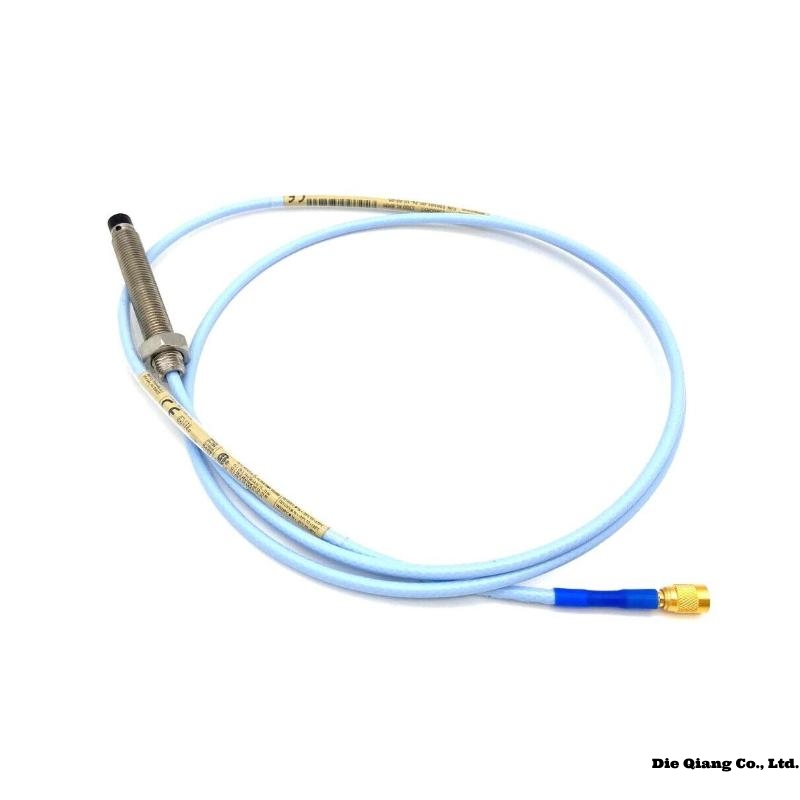

The Bently Nevada 330105-02-12 is part of the highly reliable 3300 XL Proximity Transducer System series, designed to provide accurate and consistent vibration monitoring and displacement measurements in rotating machinery. Utilizing advanced eddy current technology, this probe delivers real-time data with exceptional precision, ensuring the safety and efficiency of critical assets.

Engineered for demanding industrial environments, the 330105-02-12 proximity probe offers excellent durability and resistance to harsh operating conditions, such as high temperatures, contamination, and mechanical stresses. It plays a crucial role in predictive maintenance strategies, reducing unplanned downtime and extending machinery life cycles.

The probe features a durable, flexible cable and rugged construction, ensuring longevity and dependable performance in a wide range of applications across various industries.

Product Advantages

-

High Measurement Accuracy

Provides highly accurate vibration and displacement readings, supporting reliable machinery diagnostics. -

Durability and Robustness

Built to withstand extreme environmental conditions, including high temperatures, oil contamination, and mechanical stress. -

Wide Compatibility

Integrates seamlessly with other components of the Bently Nevada 3300 XL series and monitoring systems. -

Ease of Installation

Flexible design with user-friendly connectors and mounting hardware simplifies installation and maintenance. -

Enhanced Machinery Protection

Supports predictive maintenance, reducing the risk of catastrophic failures and improving operational efficiency. -

Stable Performance

Delivers consistent output even under fluctuating operating conditions, ensuring reliable long-term monitoring.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330105-02-12 |

| Probe Tip Diameter | 8 mm |

| Length | 305 mm (12 in) |

| Weight | 0.7 kg |

| Power Supply Voltage | -24 VDC to -28 VDC |

| Output Voltage | 7.87 V/mm (200 mV/mil) |

| Sensitivity | 200 mV/mil (±5%) |

| Frequency Range | 0 Hz to 10 kHz |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Probe Material | Stainless steel |

| Cable Length | 0.5m |

| Environmental Sealing | IP65 |

| Certifications | CE, CSA, ATEX, IECEx |

Product Applications

-

Gas and Steam Turbines

Continuous vibration monitoring ensures safe operation and early fault detection. -

Compressors

Helps prevent equipment failure by detecting imbalance, misalignment, and bearing wear. -

Pumps and Fans

Enables predictive maintenance by monitoring bearing conditions and shaft movement. -

Gearboxes

Detects abnormal vibration signatures indicating gear damage or misalignment. -

Industrial Motors

Protects motor systems by monitoring shaft position and vibration levels. -

Oil & Gas, Power Generation, Petrochemical Industries

Widely used in critical process machinery to prevent unplanned outages and ensure operational safety.

Compatible Models

The Bently Nevada 330105-02-12 is designed to be used alongside the following models:

-

3300 XL Proximitor Sensor (3300 XL 8 mm series)

-

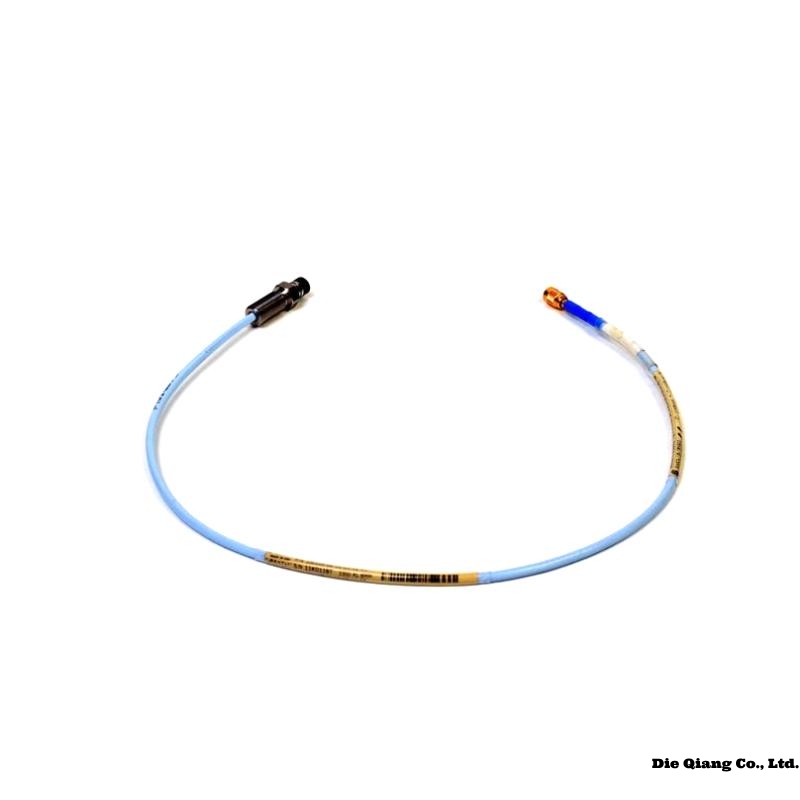

3300 XL Extension Cable

-

3500/42M Proximitor Monitor

-

3500/22M Transient Data Interface

-

330104-00-12-10-02-00 Proximity Probe

-

330130-040-00-00 Extension Cable

-

Bently Nevada 330500 Velomitor Sensor

Installation Guide

-

Preparation

Ensure all components are clean and free from damage. Verify compatibility with the monitoring system. -

Mounting the Probe

Secure the probe using the appropriate mounting bracket. Ensure the probe tip is aligned with the target shaft surface. -

Adjust Gap

Set the correct probe-to-target gap distance according to manufacturer recommendations (typically 2 mm). -

Connect Extension Cable

Attach the extension cable between the probe and proximitor sensor, ensuring firm and secure connections. -

Wiring the System

Connect the proximitor sensor to the monitoring system, following the correct wiring diagram for power and signal lines. -

System Testing

Power on the system and check the output signal. Perform calibration if necessary to ensure accurate measurements. -

Maintenance Check

Periodically inspect the probe and cables for wear or damage and replace if required.

Recommended Related Models (Same Series)

| Model Number | Probe Tip Diameter | Length | Weight | Voltage |

|---|---|---|---|---|

| 330105-02-12 | 8 mm | 305 mm | 180 g | -24 to -28 VDC |

| 330105-02-05-05-02-00 | 8 mm | 127 mm | 150 g | -24 to -28 VDC |

| 330105-02-10-10-02-00 | 8 mm | 254 mm | 170 g | -24 to -28 VDC |

| 330104-00-14-10-02-00 | 5 mm | 305 mm | 160 g | -24 to -28 VDC |

| 330130-040-00-00 | Extension Cable | 4 m | 250 g | N/A |

| 330106-05-30-10-02-00 | 11 mm | 381 mm | 230 g | -24 to -28 VDC |

Recommended Popular Models (Same Brand)

| Model Number | Application | Probe Tip Diameter | Length | Weight | Voltage |

|---|---|---|---|---|---|

| 330104-00-12-10-02-00 | General Purpose Proximity Probe | 5 mm | 305 mm | 160 g | -24 to -28 VDC |

| 330500-02-00 | Velomitor Piezoelectric Velocity | N/A | N/A | 210 g | Powered via Monitor |

| 3500/42M | Proximitor Monitor | N/A | N/A | 2.5 kg | 19 to 30 VDC |

| 3500/22M | Transient Data Interface | N/A | N/A | 2.4 kg | 19 to 30 VDC |

| 330130-040-00-00 | Extension Cable | N/A | 4 m | 250 g | N/A |

| 330780-91-05 | Air Gap Sensor | N/A | N/A | 200 g | -24 to -28 VDC |

| 330850-51-05 | Differential Expansion Probe | N/A | 305 mm | 180 g | -24 to -28 VDC |

| 86517-01 | Accelerometer | N/A | N/A | 120 g | Powered via Monitor |

FAQ (Q&A Format)

Q1: What is the typical application of the Bently Nevada 330105-02-12?

A1: The 330105-02-12 is primarily used for vibration and displacement monitoring in rotating machinery such as turbines, compressors, and pumps.

Q2: Can this probe operate in high-temperature environments?

A2: Yes, it is designed to operate in temperatures ranging from -35°C to +177°C, making it suitable for harsh industrial environments.

Q3: Is the 330105-02-12 compatible with the 3500 Series monitoring systems?

A3: Absolutely. It works seamlessly with Bently Nevada’s 3500/42M Proximitor Monitor and 3500/22M Transient Data Interface.

Q4: How often should the probe be inspected or maintained?

A4: Regular inspection is recommended during routine maintenance checks, typically every 6 to 12 months, depending on operating conditions.

Q5: What is the correct installation gap for optimal performance?

A5: The recommended probe-to-target gap is usually around 2 mm, but always refer to the specific system calibration guide.

Q6: Can the probe withstand exposure to oil and contaminants?

A6: Yes, the probe has excellent resistance to oil contamination and other industrial pollutants, ensuring reliable performance in harsh environments.

Bently Nevada 330105-02-12 3300 XL 8 mm Reverse Mount Probes

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||