| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

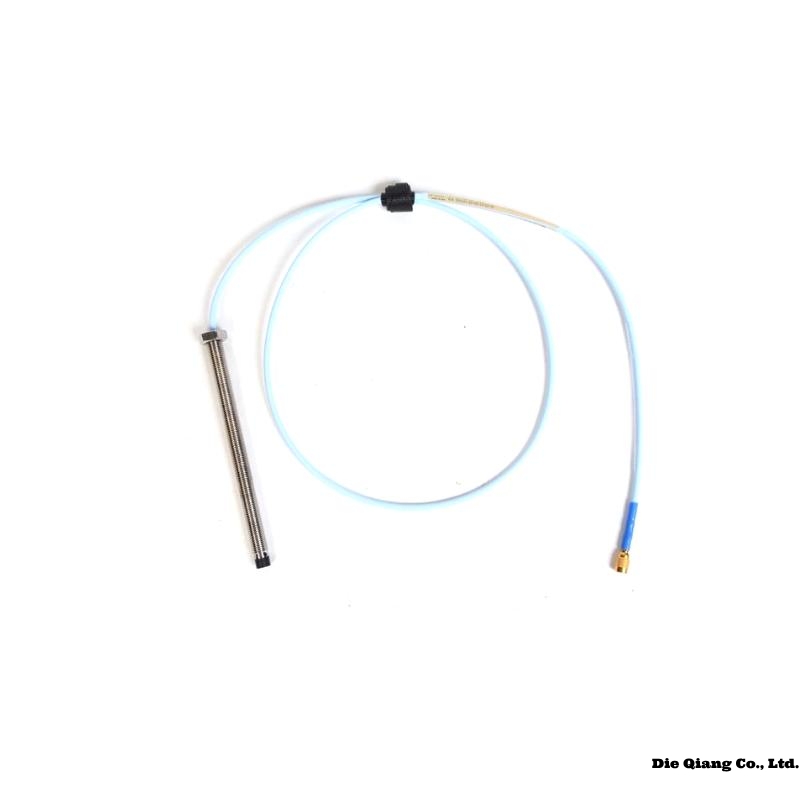

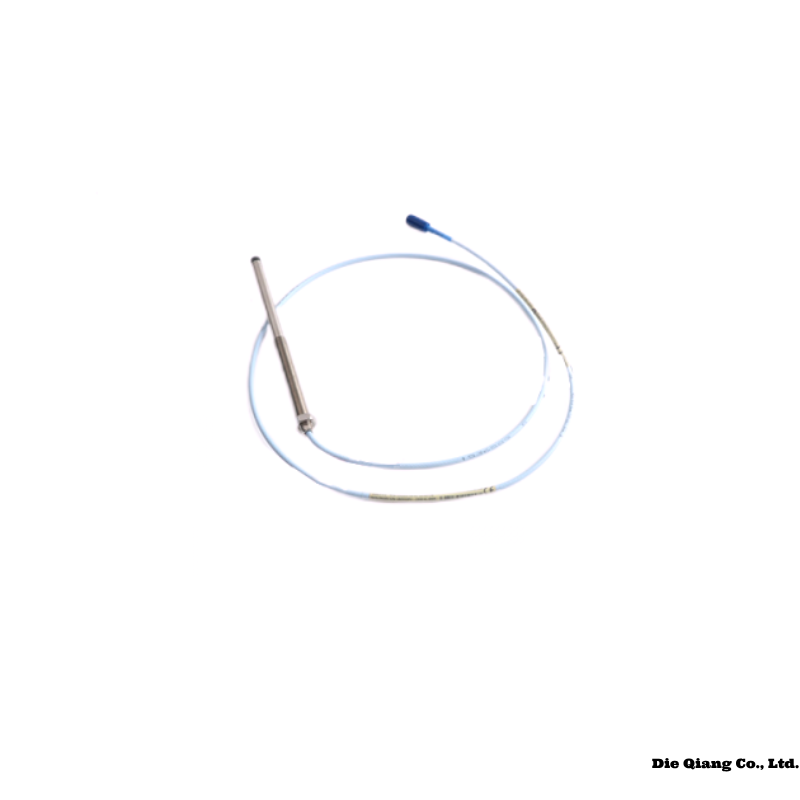

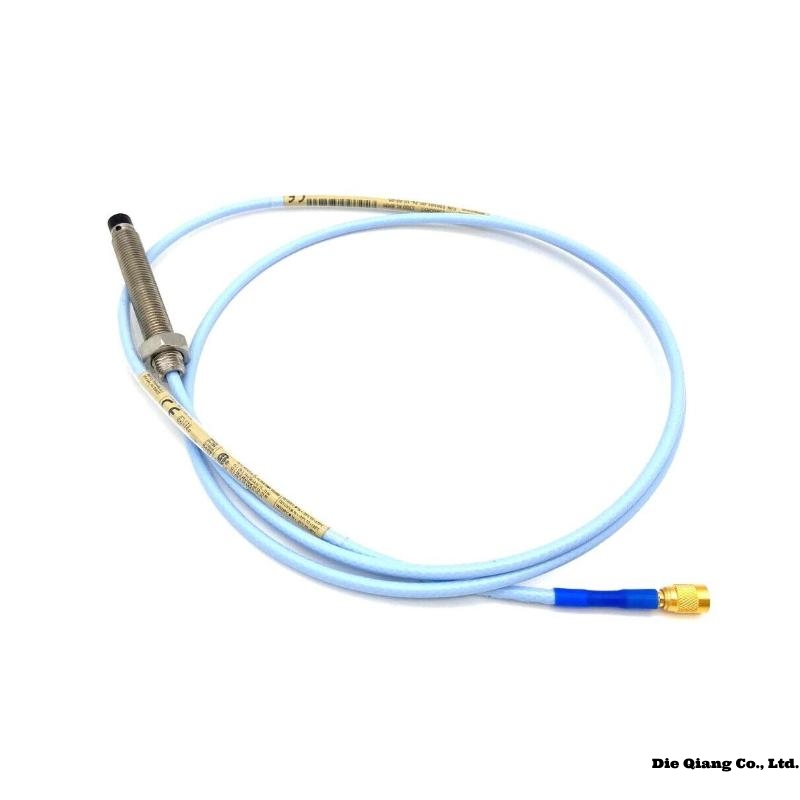

Bently Nevada 330106-05 Proximity Probe Product Overview

The Bently Nevada 330106-05 is a premium-quality proximity probe, part of the renowned 3300 XL series designed for advanced industrial monitoring applications. This probe is specifically engineered to deliver precise and reliable measurements of shaft position and vibration in rotating machinery. It utilizes eddy current sensing technology to provide accurate, real-time data essential for predictive maintenance and machinery protection.

The 330106-05 probe is crafted with robust materials to withstand harsh industrial environments, including extreme temperatures, high humidity, and potential chemical exposure. Its versatility ensures compatibility with a wide range of Bently Nevada monitoring systems, making it a preferred choice in industries such as power generation, oil and gas, petrochemicals, and heavy machinery manufacturing.

The probe features a durable stainless steel probe tip, high-performance coaxial cable, and excellent electrical insulation to prevent signal interference. This ensures long-term stability and accuracy in even the most challenging operational settings.

Product Advantages

-

Exceptional Measurement Accuracy

Provides high precision in shaft displacement and vibration monitoring, ensuring effective machinery diagnostics. -

Robust Environmental Tolerance

Operates reliably in extreme industrial environments, with resistance to high temperatures, moisture, and corrosive substances. -

Enhanced Compatibility

Fully compatible with Bently Nevada 3300 XL series systems and other monitoring setups, allowing flexible system integration. -

Durable Construction

Built with high-quality stainless steel and insulated coaxial cable, offering excellent mechanical strength and corrosion resistance. -

Low Signal Interference

Designed with superior insulation and shielding to minimize electromagnetic interference, ensuring reliable data transmission. -

Simplified Installation and Maintenance

Pre-calibrated for quick setup and features field-replaceable components to reduce downtime and maintenance costs.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330106-05 |

| Probe Tip Material | Stainless Steel |

| Cable Length | 0.5m |

| System Power Supply Voltage | -24 VDC (supplied by monitor) |

| Weight | 0.7 kg |

| Probe diameter | 8 mm |

| Sensitivity | 7.87 mV/µm (200 mV/mil) |

| Measurement Range | 2 mm (80 mils) |

| Operating Temperature Range | -35°C to +175°C (-31°F to +347°F) |

| Insulation Resistance | >10 MΩ |

| Probe Thread Size | 3/8-24 UNF |

| Vibration Limit | 10 g peak |

| Shock Limit | 1000 g peak |

| Mounting | Threaded, requires appropriate sleeve or bracket |

| Compliance | RoHS compliant, CE marked |

Applications

-

Turbomachinery Monitoring

Accurate detection of shaft vibration and displacement in steam turbines, gas turbines, and hydro turbines. -

Compressors and Pumps

Ensures early detection of imbalance, misalignment, and bearing wear. -

Generators

Continuous monitoring of generator rotors to prevent catastrophic failure. -

Petrochemical Industry Equipment

Used extensively in refineries and petrochemical plants for rotating equipment protection. -

Marine Propulsion Systems

Provides reliable monitoring in shipboard propulsion machinery. -

Industrial Fans and Blowers

Monitors shaft position to maintain operational efficiency and prevent breakdowns.

Compatible Models

The Bently Nevada 330106-05 is designed to integrate seamlessly with a variety of Bently Nevada monitors and systems, including:

-

Bently Nevada 3300 XL Proximitor Sensor

-

Bently Nevada 3300 XL Extension Cable

-

Bently Nevada 3500 Monitoring System

-

Bently Nevada 3701/40 TMR Machinery Protection System

-

Bently Nevada 1900/65A General Purpose Monitor

-

Bently Nevada ADAPT 3701/55 System

Installation Instructions

-

Preparation

Ensure the equipment is de-energized and the work area is clean. Verify that the probe tip and mounting surface are free of contaminants. -

Mounting the Probe

Thread the probe into the mounting location using the appropriate bracket or sleeve. Tighten to the recommended torque to ensure stability. -

Positioning

Adjust the probe position to achieve the target gap distance from the monitored shaft. Use a feeler gauge to confirm precise spacing. -

Routing the Cable

Route the coaxial cable carefully to avoid sharp bends and prevent damage. Secure the cable with clips or ties, maintaining a minimum bend radius. -

Connecting to the Proximitor

Connect the probe cable to the Bently Nevada Proximitor Sensor. Verify secure, tight connections. -

Calibration and Testing

Power up the system and perform initial calibration as per the Proximitor Sensor manual. Confirm correct output signals and gap voltage readings. -

Final Verification

Inspect the full installation for any loose components or potential hazards. Document installation parameters for future reference.

6 Related Models (Same Series/Family)

| Model Number | Cable Length | Measurement Range | Operating Temperature | Weight | Dimensions (Probe tip / Cable) |

|---|---|---|---|---|---|

| 330106-10 | 10 meters | 2 mm (80 mils) | -35°C to +175°C | 0.5 kg | Ø8 mm; 50 mm; Cable: 10 m |

| 330106-15 | 15 meters | 2 mm (80 mils) | -35°C to +175°C | 0.7 kg | Ø8 mm; 50 mm; Cable: 15 m |

| 330103-00-05-10-02-00 | 5 meters | 2 mm (80 mils) | -35°C to +175°C | 0.3 kg | Ø8 mm; 50 mm; Cable: 5 m |

| 330104-00-05-10-02-00 | 5 meters | 4 mm (160 mils) | -35°C to +175°C | 0.3 kg | Ø8 mm; 50 mm; Cable: 5 m |

| 330130-040-00-00 | 4 meters | 2 mm (80 mils) | -35°C to +175°C | 0.25 kg | Ø8 mm; 50 mm; Cable: 4 m |

| 330105-02-12-05-02-CN | 2 meters | 2 mm (80 mils) | -35°C to +175°C | 0.2 kg | Ø8 mm; 50 mm; Cable: 2 m |

8 Popular Models from Bently Nevada

| Model Number | Type | Measurement Range | Operating Temperature | Weight | Dimensions (Tip / Cable) | Voltage |

|---|---|---|---|---|---|---|

| 330106-05 | Proximity Probe | 2 mm | -35°C to +175°C | 0.3 kg | Ø8 mm; 50 mm; Cable: 5 m | -24 VDC |

| 3500/42M | Vibration Monitor Module | N/A | 0°C to +65°C | 0.45 kg | Module: 241 x 24 x 241 mm | 24 VDC |

| 330130-040-00-00 | Extension Cable | N/A | -35°C to +175°C | 0.25 kg | Cable: 4 m | N/A |

| 330104-00-05-10-02-00 | Proximity Probe | 4 mm | -35°C to +175°C | 0.3 kg | Ø8 mm; 50 mm; Cable: 5 m | -24 VDC |

| 1900/65A | General Purpose Monitor | N/A | -30°C to +65°C | 1.0 kg | 300 x 75 x 150 mm | 24 VDC |

| 3500/25 | Keyphasor Module | N/A | 0°C to +65°C | 0.5 kg | 241 x 24 x 241 mm | 24 VDC |

| 330500 | Velocity Sensor | ±127 mm/s | -55°C to +121°C | 0.4 kg | Ø32 mm; Length: 76 mm | N/A |

| 3701/40 | TMR Monitor | N/A | -30°C to +65°C | 1.2 kg | 305 x 102 x 230 mm | 24 VDC |

Frequently Asked Questions (FAQ)

Q1: What is the typical application of the Bently Nevada 330106-05?

A1: The 330106-05 is primarily used for shaft position and vibration monitoring in rotating machinery such as turbines, compressors, and pumps. It ensures early detection of mechanical issues to prevent unplanned downtime.

Q2: Can the 330106-05 be used in high-temperature environments?

A2: Yes, the 330106-05 operates reliably in temperatures ranging from -35°C to +175°C, making it suitable for harsh industrial applications.

Q3: What is the recommended installation procedure for this probe?

A3: Installation involves securing the probe with the correct torque, setting the gap to the target value, properly routing the cable, and calibrating the system with the Proximitor Sensor. Detailed steps are provided in the installation section above.

Q4: Is the probe compatible with the Bently Nevada 3500 monitoring system?

A4: Yes, the 330106-05 is fully compatible with the Bently Nevada 3500 series, ensuring seamless integration for comprehensive machinery protection.

Q5: How often does the probe require maintenance?

A5: The 330106-05 is designed for low maintenance. However, regular inspection during routine equipment shutdowns is recommended to check for wear, secure connections, and cable integrity.

Q6: What is the expected lifespan of the 330106-05 in continuous operation?

A6: With proper installation and maintenance, the 330106-05 can provide reliable service for over 5–7 years, even under continuous industrial operation.

Bently Nevada 330106-05 3300 XL 8 mm Reverse Mount Probes

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||