| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

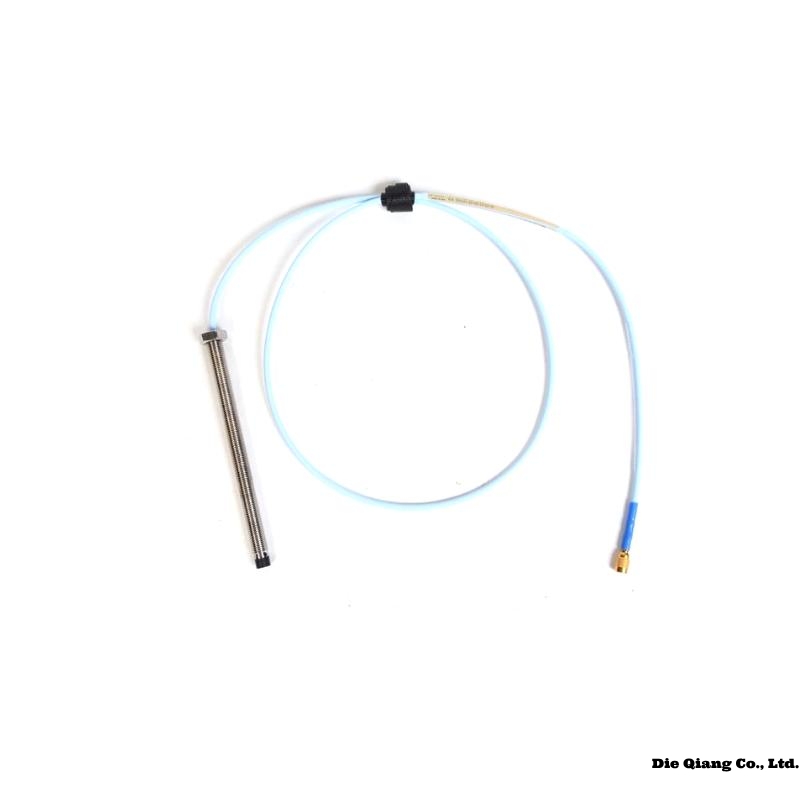

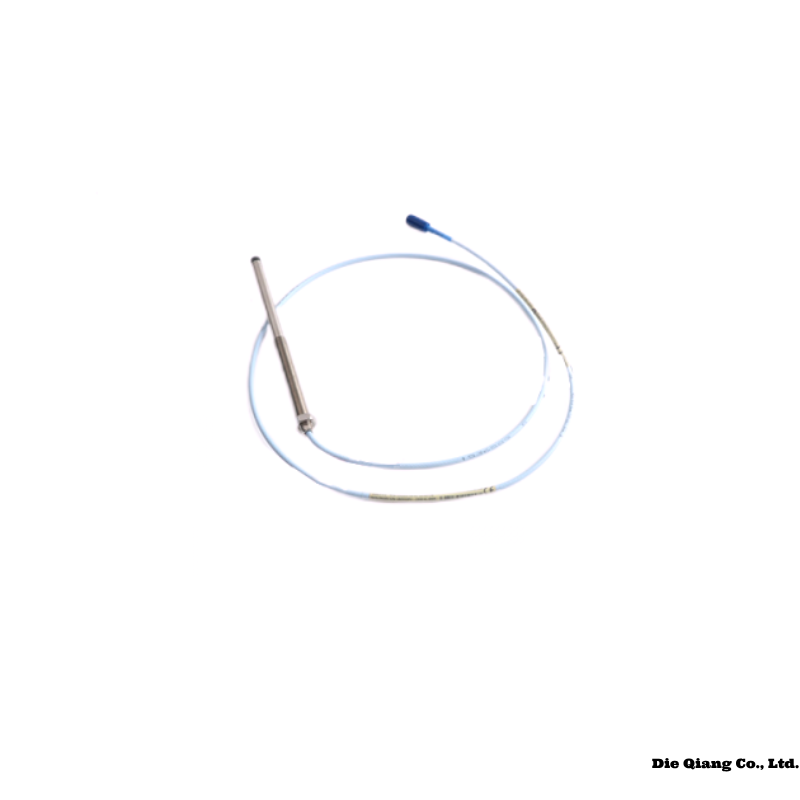

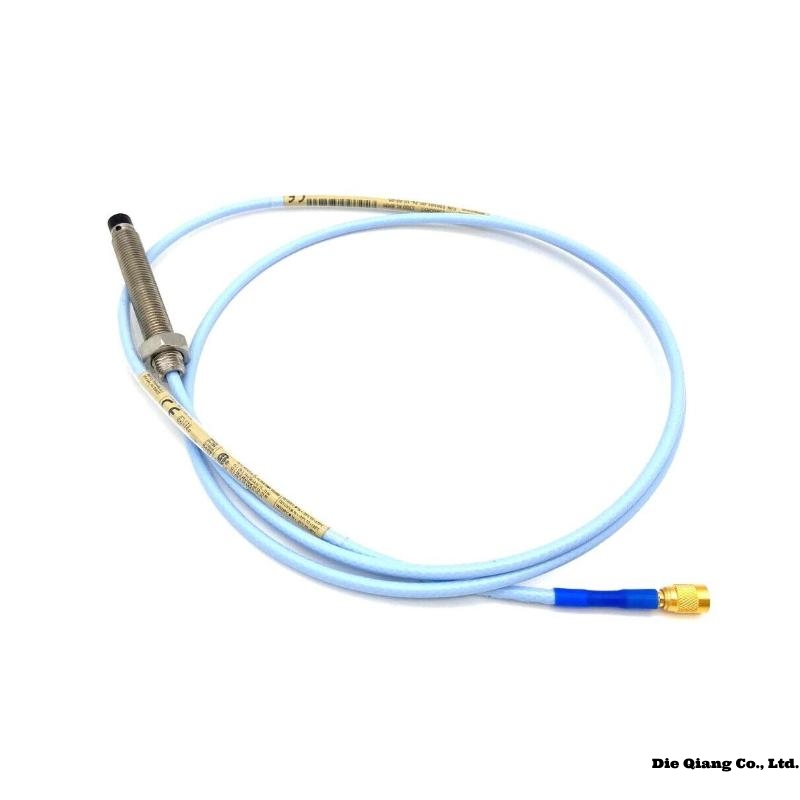

Bently Nevada 330180-X0-05 Detailed Product Documentation

Product Introduction

The Bently Nevada 330180-X0-05 extension cable is an essential component of the renowned 3300 XL series vibration monitoring system. Specifically designed to connect the proximity probe and the proximity transducer, this extension cable plays a pivotal role in ensuring accurate signal transmission over extended distances in industrial environments.

Known for its robust design, the 330180-X0-05 is engineered to withstand harsh conditions, including high temperatures, oil contamination, and mechanical stress. It guarantees stable performance in critical machinery monitoring applications, where precision and reliability are non-negotiable.

With Bently Nevada’s longstanding reputation for excellence in condition monitoring solutions, the 330180-X0-05 continues to be a preferred choice for industries ranging from oil & gas to power generation and manufacturing.

Product Advantages

-

High Reliability

Engineered for harsh industrial conditions, providing consistent performance in environments with high temperatures, oil contamination, and vibration. -

Exceptional Signal Integrity

Ensures accurate data transmission between the probe and transducer, minimizing signal degradation over long distances. -

Durability and Longevity

Made from premium-grade materials that resist wear, chemical exposure, and mechanical stress, extending the service life of the system. -

Ease of Installation

Flexible construction with clear labeling allows for quick and straightforward installation, reducing maintenance time. -

Compatibility

Fully compatible with the entire Bently Nevada 3300 XL series, ensuring seamless integration with existing systems. -

Reduced Downtime

By ensuring accurate condition monitoring, it helps prevent unexpected equipment failures, maximizing operational uptime.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330180-X0-05 |

| Cable Length | 5 meters |

| Cable Type | Coaxial extension cable |

| Connector Type | ClickLoc Connectors |

| Operating Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Weight | 0.246 kg |

| Outer Diameter | 4.1 mm (0.16 inches) |

| Voltage Rating | 300 V RMS |

| Insulation Resistance | > 1000 MΩ at 500 VDC |

| Vibration Resistance | 20 g, 10–2000 Hz |

| Certifications | CE, CSA, ATEX |

| Compatibility | Bently Nevada 3300 XL Proximity System |

Product Applications

-

Oil & Gas Industry

Used in rotating equipment such as compressors, pumps, and turbines for reliable vibration monitoring. -

Power Generation

Monitors turbine shaft vibrations to prevent catastrophic failures. -

Petrochemical Plants

Ensures continuous monitoring of critical process machinery. -

Manufacturing Facilities

Applied in heavy-duty machinery like fans, motors, and gearboxes. -

Marine and Offshore Platforms

Provides essential condition monitoring in rugged environments. -

Pulp & Paper Industry

Enhances the reliability of paper machines and associated rotating equipment.

Compatible Models

-

3300 XL 8 mm Proximity Probe

-

3300 XL Proximitor Sensor

-

3300 XL Extension Cable (various lengths)

-

330130-080-00-00 Probe Cable

-

330101 Proximity Probe

-

330104 Proximity Transducer

The 330180-X0-05 serves as the vital link between these components, ensuring accurate and stable data communication.

Installation Instructions

-

Preparation

Verify that the cable length and connectors are appropriate for your specific installation. Inspect for any visible damage before installation. -

Connection to Proximity Probe

Attach one end of the 330180-X0-05 to the 3300 XL proximity probe using the ClickLoc connector. Ensure a secure fit to avoid signal loss. -

Routing the Cable

Route the cable away from high-voltage lines and mechanical pinch points. Use cable ties to secure the cable along its path, allowing for some movement to prevent stress. -

Connection to Proximitor Sensor

Connect the other end of the cable to the 3300 XL Proximitor Sensor. Confirm proper seating of the connection. -

System Testing

Power up the system and check for proper operation. Verify signal integrity using appropriate diagnostic tools. -

Final Inspection

Conduct a final inspection to ensure all connections are tight and the cable is free from mechanical stress or interference.

6 Related Models (with Specifications)

| Model Number | Cable Length | Temperature Range | Weight | Voltage Rating | Outer Diameter |

|---|---|---|---|---|---|

| 330180-XX-10 | 10 meters | -51°C to +177°C | 0.7 kg | 300 V RMS | 4.1 mm |

| 330180-XX-15 | 15 meters | -51°C to +177°C | 1.0 kg | 300 V RMS | 4.1 mm |

| 330130-080-00-00 | 8 meters | -51°C to +177°C | 0.56 kg | 300 V RMS | 4.1 mm |

| 330101-00-08-10-02-00 | 8 meters | -51°C to +177°C | 0.5 kg | 300 V RMS | 4.1 mm |

| 330104-00-08-10-02-00 | 8 meters | -51°C to +177°C | 0.52 kg | 300 V RMS | 4.1 mm |

| 330178-XX-05 | 5 meters | -51°C to +177°C | 0.35 kg | 300 V RMS | 4.1 mm |

8 Popular Bently Nevada Models (with Specifications)

| Model Number | Description | Application | Temperature Range | Weight | Voltage Rating | Certifications |

|---|---|---|---|---|---|---|

| 3300 XL Proximitor Sensor | Proximity Transducer System | Rotating Equipment Monitoring | -51°C to +177°C | 0.45 kg | 24 VDC | CE, CSA, ATEX |

| 3300 XL 8 mm Probe | Proximity Probe | Shaft Vibration Measurement | -51°C to +177°C | 0.2 kg | Passive | CE, CSA |

| 3500/42M Monitor | Vibration Monitor Module | Machinery Protection Systems | -30°C to +65°C | 1.2 kg | 24 VDC | CE, CSA, ATEX |

| 3500/22M Transient Card | Transient Data Interface | Event Monitoring | -30°C to +65°C | 0.8 kg | 24 VDC | CE, CSA, ATEX |

| 330500 Velomitor Sensor | Velocity Sensor | General Vibration Monitoring | -51°C to +121°C | 0.4 kg | Passive | CE |

| 3500/15 Power Supply Module | Power Supply Unit | 3500 Series System | -30°C to +65°C | 1.6 kg | 24/125 VDC | CE, CSA, ATEX |

| 190501 Velomitor Piezo | Piezoelectric Velocity Transducer | Equipment Vibration Monitoring | -40°C to +120°C | 0.37 kg | Passive | CE, CSA |

| 3500/93 System Display | Rack Display Unit | System Status Display | -30°C to +65°C | 1.4 kg | 24 VDC | CE, CSA, ATEX |

FAQ (Q&A Format)

Q1: What is the main purpose of the Bently Nevada 330180-X0-05?

A1: The 330180-X0-05 extension cable is designed to connect the proximity probe to the proximitor sensor, ensuring accurate and reliable signal transmission in machinery monitoring systems.

Q2: Can the 330180-X0-05 cable be used in high-temperature environments?

A2: Yes, the cable is rated for temperatures ranging from -51°C to +177°C, making it suitable for demanding industrial applications.

Q3: Is the 330180-X0-05 compatible with older Bently Nevada systems?

A3: It is primarily designed for the 3300 XL series but may be compatible with some legacy systems. Compatibility should be confirmed with the manufacturer.

Q4: How can I verify if my 330180-X0-05 cable is functioning properly?

A4: System diagnostics tools can be used to check signal integrity and connectivity between the proximity probe and proximitor sensor.

Q5: Does this cable require special installation tools?

A5: No, standard hand tools are sufficient for installation. The ClickLoc connectors make the installation process straightforward and tool-friendly.

Q6: What should I do if the cable is exposed to oil or contaminants?

A6: The cable is designed to resist oil and chemical exposure. However, it is advisable to clean it periodically to maintain optimal performance.

Bently Nevada 330180-X0-05 3300 XL 5/8mm Proximitor Sensor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||