| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

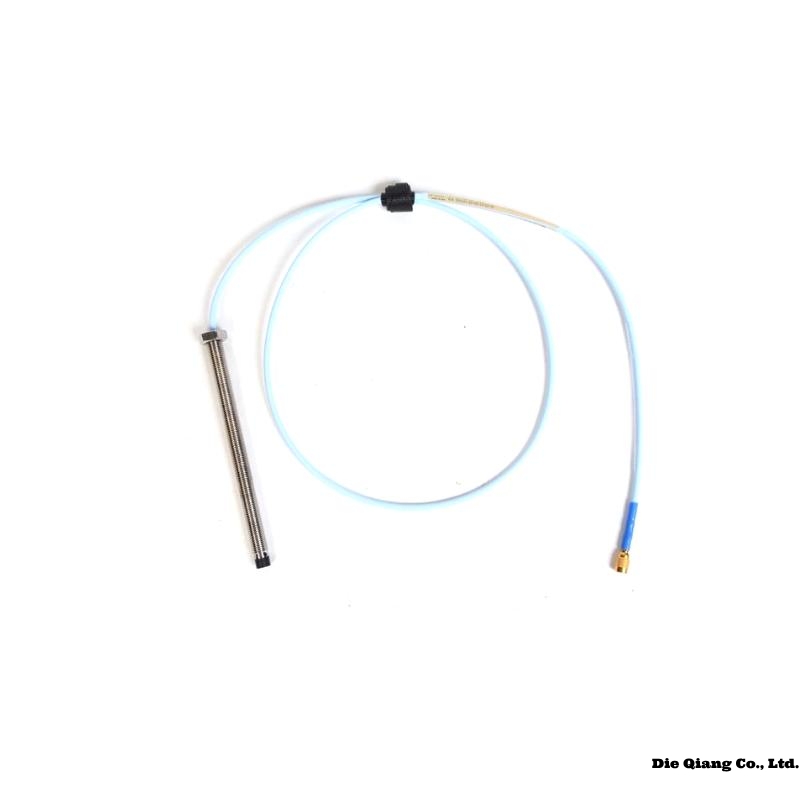

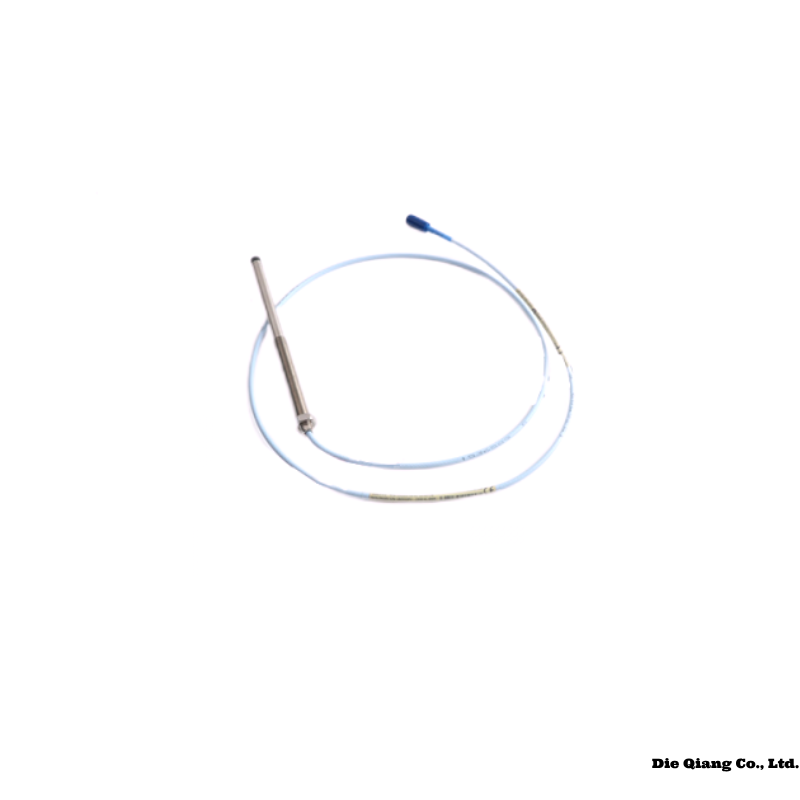

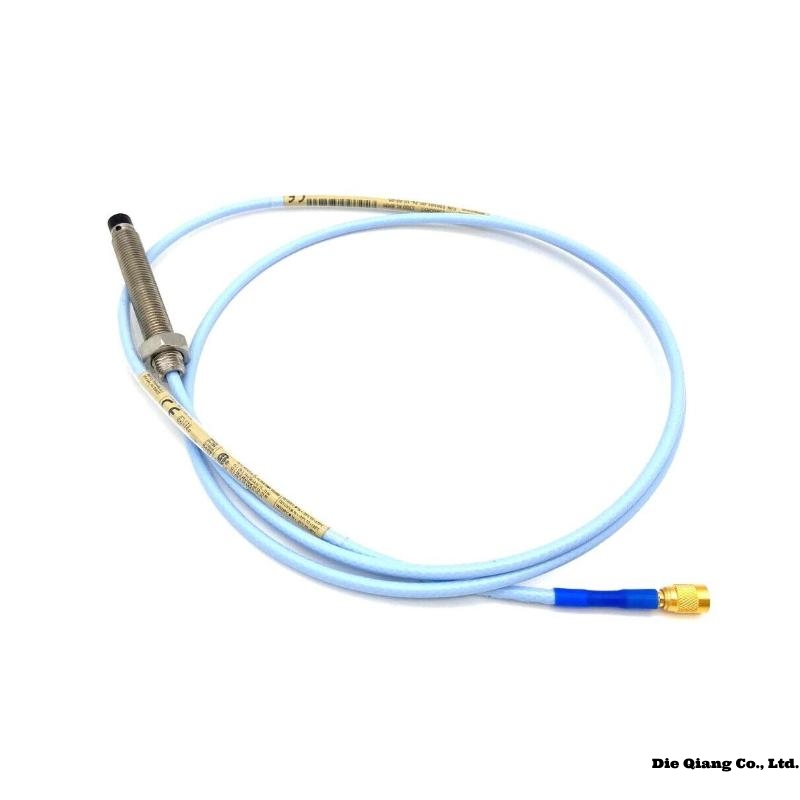

Bently Nevada 330703-000-080-10-02-00

Product Introduction

The Bently Nevada 330703-000-080-10-02-00 is a proximity probe designed for machinery condition monitoring, particularly in high-speed rotating equipment. This probe is part of the renowned 3300 XL series, developed for applications requiring precise, non-contact measurement of shaft displacement, position, and vibration.

With robust construction and high immunity to environmental interference, the 330703 probe offers long-term stability, accuracy, and reliability in industrial environments. Its design supports ease of integration with Bently Nevada monitoring systems and supports API 670 compliance, making it ideal for use in critical asset protection systems such as turbines, compressors, and pumps.

This probe is engineered to withstand harsh operating conditions including high temperature, vibration, and electromagnetic interference. It is fully compatible with Bently Nevada proximitor sensors and extension cables, forming a complete proximity transducer system.

Product Advantages

-

High Precision: Offers accurate and consistent non-contact measurement of shaft displacement, vibration, and axial position.

-

Rugged Design: Built to perform reliably in demanding industrial environments with high levels of vibration and temperature.

-

Long-Term Stability: Designed to provide stable performance with minimal drift over time, reducing the need for recalibration.

-

API 670 Compliant: Meets the stringent standards required for machinery protection systems in the oil & gas and power generation industries.

-

Wide Compatibility: Seamlessly integrates with other Bently Nevada components, including proximitor sensors and extension cables.

-

Ease of Installation: Features threaded connections and flexible cable lengths for simplified and secure mounting.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330703-000-080-10-02-00 |

| Series | 3300 XL Series |

| Probe Tip Diameter | 5 mm |

| Sensing Distance | 2 mm nominal |

| Cable Length | 1m |

| Connector Type | Miniature coaxial |

| Case Material | AISI 304 Stainless Steel |

| Mounting Thread | 3/8-24 UNF-2A |

| Weight | 0.255kg |

| Operating Temperature | -35°C to +177°C (-31°F to +350°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Relative Humidity | 0–95% non-condensing |

| Input Voltage | ±24 VDC (from proximitor sensor) |

| Output Voltage Range | 0 to -24 VDC |

| Linearity | ±0.25 mils over the linear range |

| Compliance | API 670, CE, RoHS |

| Insulation Resistance | >10 MΩ at 500 VDC |

| Vibration Limit | 10 g peak, 10–2000 Hz |

Product Applications

-

Steam and Gas Turbines

-

Centrifugal and Reciprocating Compressors

-

Industrial Fans and Blowers

-

High-speed Motors and Generators

-

Pumps (Centrifugal and Positive Displacement)

-

Gearboxes and Rotating Shafts

The 330703 proximity probe is critical in vibration monitoring and axial position detection, enabling predictive maintenance strategies and preventing unexpected machinery failure.

Compatible Models

This probe is designed to operate in conjunction with the following Bently Nevada components:

-

3300 XL Proximitor Sensor (e.g., 330180-50)

-

3300 XL Extension Cable (e.g., 330130-080-00-CN)

-

3300 Monitoring Systems (e.g., 3500 Series Racks)

-

Bently Nevada Vibration Monitoring Modules (e.g., 3500/40M, 3500/42M)

-

330101, 330102, and 330104 Series Extension Cables

Installation Instructions

-

Preparation:

Ensure all system power is off. Verify all components including probes, cables, and proximitor sensors are clean and undamaged. -

Mounting the Probe:

Thread the probe into the designated mounting port using the correct torque specification. Use lock nuts or epoxy as required. -

Gap Adjustment:

Use a dial gauge or micrometer to adjust the gap between the probe tip and shaft to approximately 2 mm (80 mils). -

Connect Cables:

Connect the probe to the extension cable, ensuring secure and moisture-proof connections. -

Route and Secure:

Route the cable away from high-voltage lines and mechanical stress. Use clamps and protective tubing as needed. -

Connect to Proximitor Sensor:

Attach the other end of the extension cable to the Proximitor Sensor and secure all connections. -

System Calibration:

Apply power and calibrate the system according to the manufacturer’s instructions or using Bently Nevada’s recommended procedure. -

Final Inspection:

Verify gap voltage and signal integrity, and document installation data for future reference.

6 Related Models from Same Series

| Model Number | Description | Cable Length | Probe Tip Diameter | Mounting Thread | Output Range |

|---|---|---|---|---|---|

| 330703-000-060-10-02-00 | 6.0 m Proximity Probe | 6.0 m | 5 mm | 3/8-24 UNF-2A | 0 to -24 VDC |

| 330703-000-040-10-02-00 | 4.0 m Proximity Probe | 4.0 m | 5 mm | 3/8-24 UNF-2A | 0 to -24 VDC |

| 330703-000-120-10-02-00 | 12.0 m Proximity Probe | 12.0 m | 5 mm | 3/8-24 UNF-2A | 0 to -24 VDC |

| 330101-00-08-10-02-00 | 5 mm Probe, Reverse Mount | 8.0 m | 5 mm | 1/4-28 UNF | 0 to -24 VDC |

| 330104-00-12-10-02-00 | 8 mm Probe, Forward Mount | 12.0 m | 8 mm | 3/8-24 UNF-2A | 0 to -24 VDC |

| 330102-00-05-10-02-00 | 5 mm Probe with 5.0 m Cable | 5.0 m | 5 mm | M10x1 | 0 to -24 VDC |

8 Popular Bently Nevada Models

| Model | Description | Voltage | Weight | Dimensions | Application |

|---|---|---|---|---|---|

| 3500/42M | Dynamic Vibration Monitor | 24 VDC | 400 g | 100 x 25 x 120 mm | Vibration monitoring |

| 3500/40M | Proximitor Monitor | 24 VDC | 380 g | 100 x 25 x 120 mm | Displacement & speed monitoring |

| 330130-080-00-CN | Extension Cable, 8.0 m | Passive | 250 g | 8 m cable length | Signal transmission |

| 330180-50-CN | Proximitor Sensor for 5 mm Probe | 24 VDC | 350 g | 100 x 30 x 70 mm | Signal conditioning |

| 330103-00-05-10-02-00 | 5 mm Probe with 5.0 m Cable | Passive | 150 g | 5 m cable + 75 mm probe | Shaft monitoring |

| 330106-05-30-10-02-00 | 8 mm Probe with 5.0 m Cable | Passive | 160 g | 5 m cable + 85 mm probe | Large shaft vibration measurement |

| 330104-00-12-10-02-00 | Forward Mount Probe, 12 m | Passive | 180 g | 12 m cable + 90 mm probe | Turbine proximity monitoring |

| 330173-00-04-10-02-00 | Probe with Armor Cable | Passive | 210 g | 4 m armored cable + 75 mm probe | Hazardous area machinery monitoring |

Frequently Asked Questions (FAQ)

Q1: What is the purpose of the Bently Nevada 330703-000-080-10-02-00?

A1: This proximity probe is used to monitor the position and vibration of rotating machinery shafts, providing data for condition monitoring and machinery protection.

Q2: Is the 330703-000-080-10-02-00 compatible with other Bently Nevada sensors?

A2: Yes, it is compatible with 3300 XL proximitor sensors and extension cables, forming a complete non-contact displacement measurement system.

Q3: Can this probe be used in high-temperature environments?

A3: Yes, the probe can operate in temperatures up to +177°C, making it suitable for turbine and compressor applications.

Q4: How is the gap between the probe and the shaft adjusted?

A4: The gap is typically adjusted using a dial indicator or feeler gauges to maintain an optimal sensing distance of around 2 mm.

Q5: What kind of calibration is required after installation?

A5: Calibration involves verifying the output voltage at known gap distances and ensuring proper signal linearity. Use Bently Nevada calibration procedures for accuracy.

Q6: Does the probe require periodic maintenance?

A6: While the probe is designed for long-term stability, periodic inspections for physical damage, cable integrity, and signal verification are recommended.

Bently Nevada 330703-000-080-10-02-00 3300 XL 11 mm Probe

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||