| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

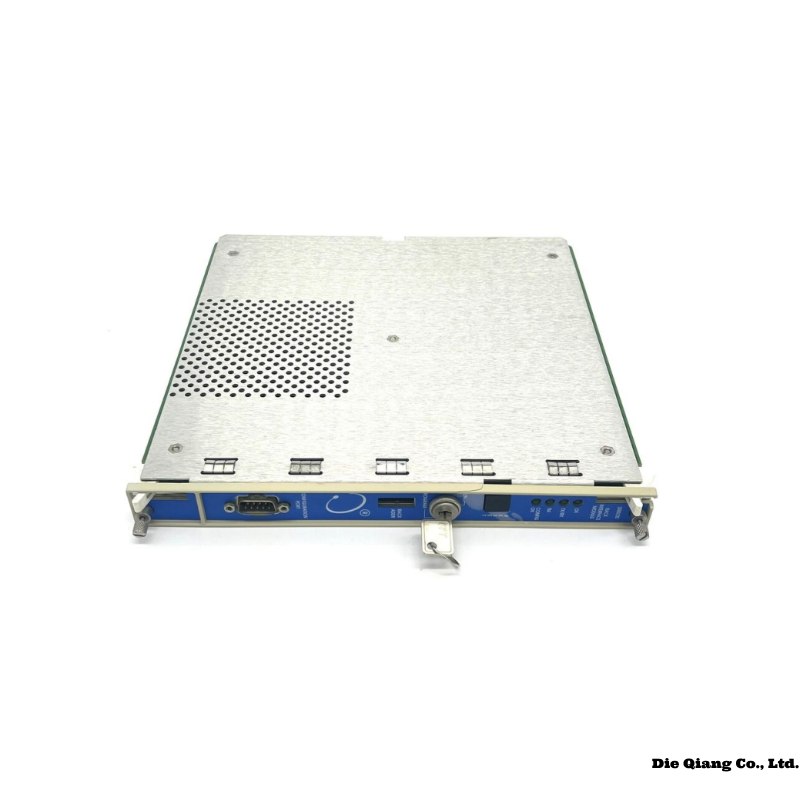

Bently Nevada 3500/22-01-01-02 Product Overview

The Bently Nevada 3500/22-01-01-02 is a 4-channel monitor module designed for vibration and position monitoring in industrial machinery. It is part of the Bently Nevada 3500 series, a widely used condition monitoring system that ensures the reliability and safety of critical rotating equipment.

This module provides continuous monitoring of machinery health by measuring parameters such as radial vibration, axial position, and speed, helping to prevent unexpected failures and reduce maintenance costs.

Product Advantages

- High Accuracy & Reliability – Provides precise measurements with minimal drift, ensuring long-term stability.

- Modular Design – Easily integrates into the 3500 rack system, allowing flexible configuration.

- Advanced Diagnostics – Features self-diagnostics and fault detection for improved system integrity.

- Wide Compatibility – Works seamlessly with various sensors, including proximity probes, accelerometers, and velocity sensors.

- Robust Construction – Designed for harsh industrial environments with high EMI resistance.

- User-Friendly Interface – Supports 3500 configuration software for easy setup and monitoring.

Technical Specifications

| Parameter | Specification |

|---|---|

| Channels | 4 (Vibration/Position) |

| Input Types | Proximity Probe, Seismic Sensor |

| Measurement Range | 0-20mA, -24V to +24V (depending on sensor) |

| Frequency Response | 0.5 Hz to 10 kHz |

| Accuracy | ±1% of full scale |

| Power Supply | 18-32V DC |

| Power Consumption | 10W (typical) |

| Operating Temp. | -30°C to +70°C |

| Dimensions | 241.3 x 24.4 x 241.8mm |

| Weight | 0.91 kg |

| Communication | RS-485, Modbus (optional) |

Applications

The 3500/22-01-01-02 is widely used in industries such as:

- Oil & Gas – Monitoring turbines, compressors, and pumps.

- Power Generation – Gas/steam turbines, generators.

- Chemical & Petrochemical – Critical rotating machinery.

- Mining & Metals – Large motors, gearboxes.

- Water Treatment – Pumps and blowers.

Compatible Models & Accessories

The module works with:

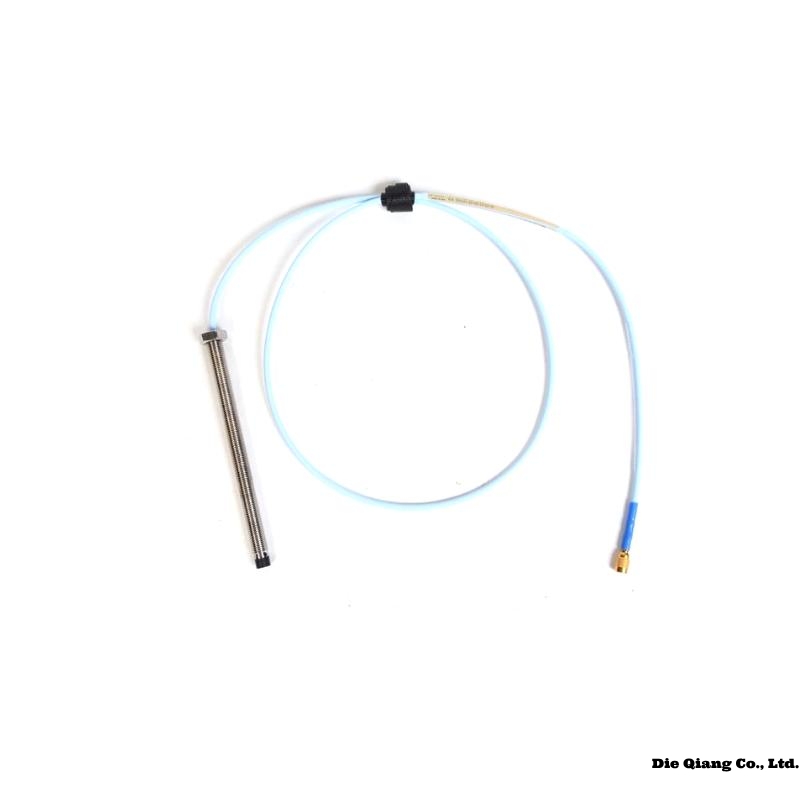

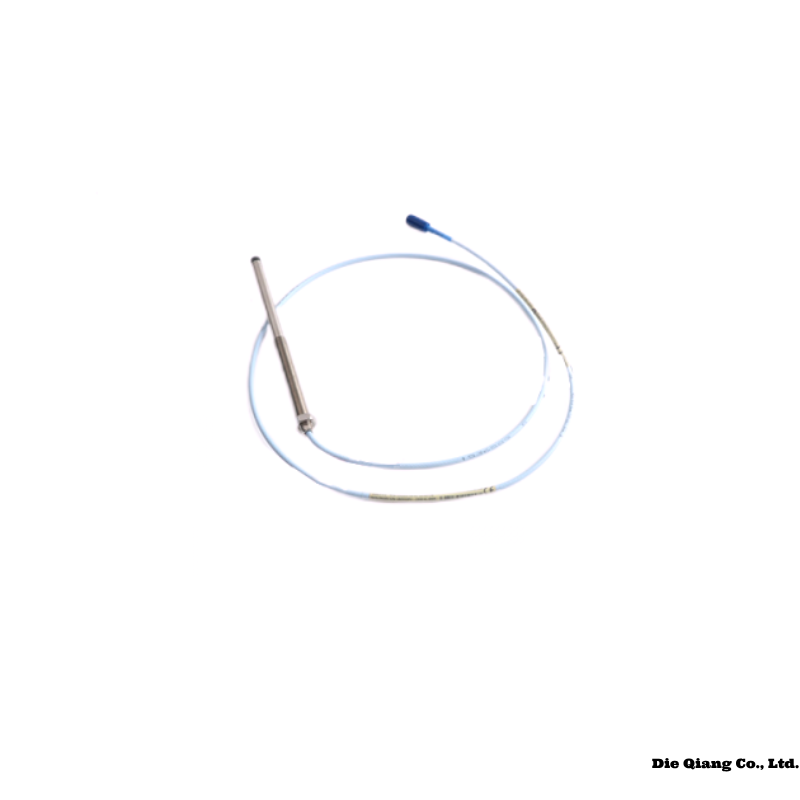

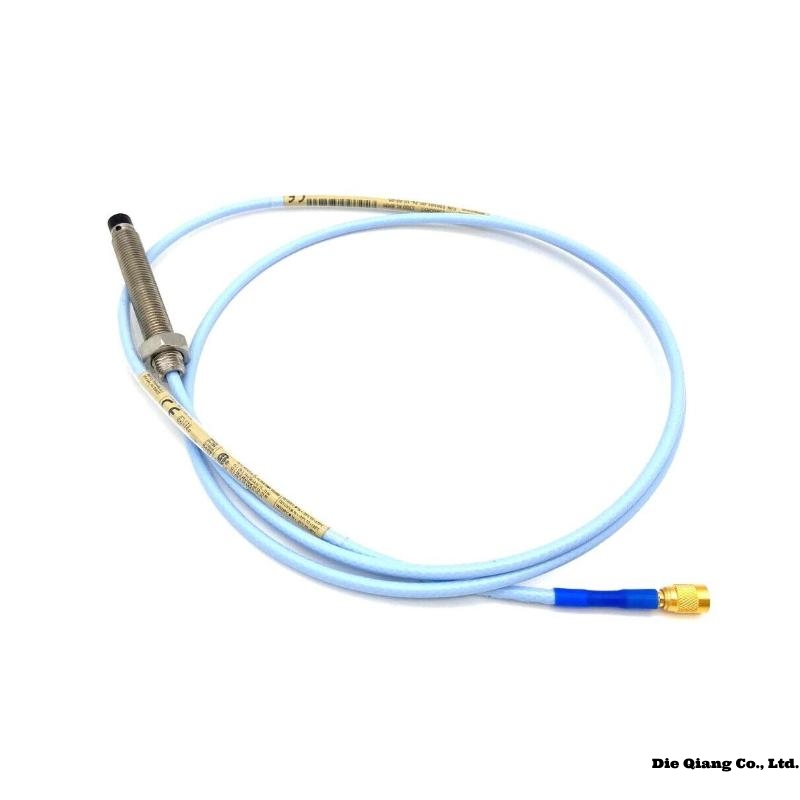

- Sensors: 3300 XL Proximity Probes, 330500 Accelerometers.

- Rack Systems: 3500/15 (Power Supply), 3500/20 (Rack Interface).

- Software: System 1™ for advanced diagnostics.

Installation Instructions

- Mounting – Install the module in a 3500 rack with proper grounding.

- Wiring – Connect sensors using shielded cables to reduce noise.

- Power-Up – Ensure voltage is within 18-32V DC before activation.

- Configuration – Use 3500 Configuration Software to set alarm thresholds and scaling.

- Testing – Verify signal integrity before full operation.

Recommended Related Models (Same Series)

| Model | Description | Channels | Input Type | Dimensions (mm) | Weight (kg) | Voltage Range |

|---|---|---|---|---|---|---|

| 3500/25 | Transient Data Interface | 1 | Digital/Analog | 200×60×150 | 1.1 | 18-32V DC |

| 3500/32 | 4-Channel Relay Module | 4 | Relay Output | 200×60×150 | 1.3 | 18-32V DC |

| 3500/42M | Proximitor Monitor | 2 | Eddy Current | 200×60×150 | 1.2 | 18-32V DC |

| 3500/50 | Speed Monitor | 1 | Magnetic Pickup | 200×60×150 | 1.0 | 18-32V DC |

| 3500/92 | Communication Gateway | – | RS-485/Ethernet | 200×60×150 | 1.4 | 18-32V DC |

| 3500/15 | Power Supply Module | – | 120/240V AC | 200×60×150 | 1.5 | 100-240V AC |

Top 8 Popular Bently Nevada Models

| Model | Description | Key Parameters | Dimensions (mm) | Weight (kg) | Voltage |

|---|---|---|---|---|---|

| 3300 XL 8mm | Proximity Probe | 8mm Range, -24V to +24V | 80×20×20 | 0.2 | 18-30V DC |

| 3500/40M | 2-Channel Monitor | Vibration/Temp | 200×60×150 | 1.2 | 18-32V DC |

| 3500/60 | Temperature Monitor | RTD/TC Input | 200×60×150 | 1.1 | 18-32V DC |

| 1900/65A | Accelerometer | 4-20mA Output | 50×30×30 | 0.3 | 18-30V DC |

| 3500/22M | Enhanced Vibration Monitor | 4-Channel | 200×60×150 | 1.3 | 18-32V DC |

| 2600T | Turbine Monitor | Speed/Vibration | 300×100×200 | 2.5 | 24V DC |

| 330850 | Velocity Sensor | 10-1000 Hz | 60×40×40 | 0.4 | 12-30V DC |

| 3500/70 | Hydraulic Monitor | Pressure/Temp | 200×60×150 | 1.4 | 18-32V DC |

FAQ (Frequently Asked Questions)

Q1: What is the difference between 3500/22 and 3500/22M?

A1: The 3500/22M has enhanced diagnostics and wider frequency response compared to the standard 3500/22.

Q2: Can this module work with third-party sensors?

A2: Yes, but optimal performance is achieved with Bently Nevada-certified sensors.

Q3: What is the maximum cable length for sensor connections?

A3: Recommended max length is 300 meters (shielded twisted pair).

Q4: How do I reset a fault alarm?

A4: Use the 3500 software or manually reset via the rack interface.

Q5: Is this module explosion-proof?

A5: No, but it can be installed in hazardous areas with proper enclosures.

Q6: What maintenance is required?

A6: Periodic calibration checks and firmware updates are recommended.

Bently Nevada 3500/22-01-01-02 Transient Data Interface

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||