| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

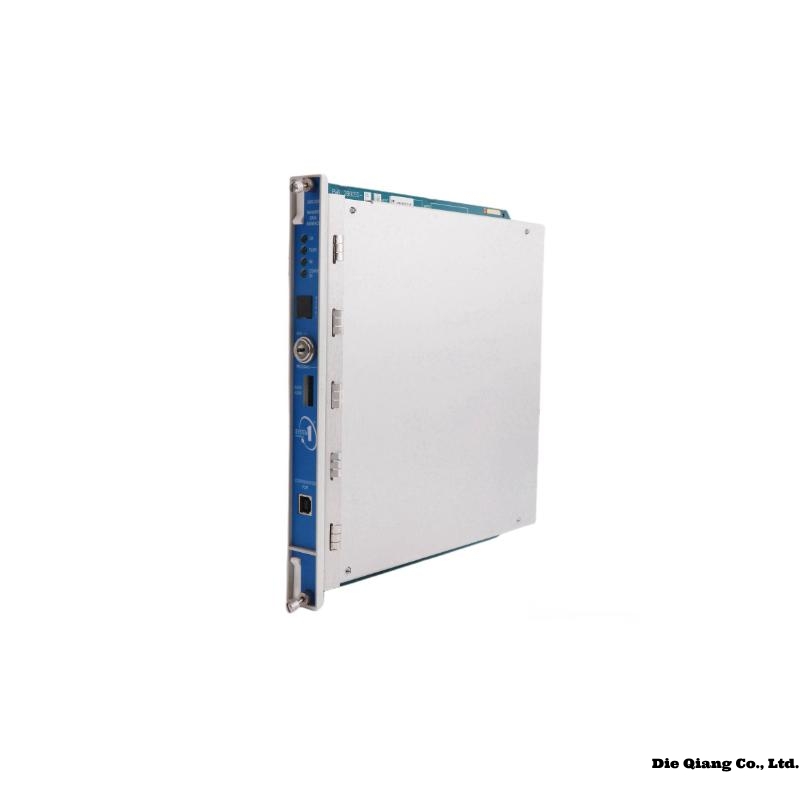

📘 Product Introduction – Bently Nevada 3500/22-01-02-00

The Bently Nevada 3500/22-01-02-00 Transient Data Interface (TDI) Module is a critical component in the Bently Nevada 3500 Series Machinery Protection System. It acts as a combined communication processor and configuration module, enabling seamless data acquisition, processing, and communication between the system’s monitoring modules and external host software, such as System 1.

This model integrates both transient and condition monitoring data, allowing users to diagnose machinery issues with speed and precision. It supports dynamic data capture, event-triggered data buffering, and is compatible with various communication interfaces, including Ethernet and Serial options.

The 3500/22-01-02-00 is widely adopted in turbine monitoring, rotating machinery diagnostics, and critical asset management across oil & gas, power generation, and petrochemical industries.

🌟 Product Advantages

-

High-speed Data Processing

Enables real-time monitoring of transient events and machinery conditions. -

Dual Communication Ports

Offers Ethernet and Serial connectivity for flexible integration with host systems. -

Integration with System 1 Software

Full compatibility with Bently Nevada’s System 1 for advanced diagnostics and analysis. -

Modular and Scalable

Supports expansion and configuration based on application-specific requirements. -

Event-triggered Data Capture

Ensures accurate recording of machine behavior during critical incidents. -

Robust Reliability

Designed for 24/7 operation in industrial environments with high electromagnetic interference.

📊 Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | 3500/22-01-02-00 |

| Function | Transient Data Interface (TDI) |

| Communication | Ethernet and Serial |

| Voltage Input | +24 VDC nominal (from rack) |

| Power Consumption | 6.2 W (typical) |

| Dimensions | 241.3 x 24.4 x 241.8mm |

| Weight | 0.91 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | 95% non-condensing |

| Mounting Type | 3500 Rack Slot 1 (Required) |

| Firmware | Field upgradeable via System 1 |

| Diagnostic LEDs | OK, TX/RX, CONFIG, COMM |

🏭 Applications

-

Gas and Steam Turbines

-

Centrifugal and Reciprocating Compressors

-

Electric Motors and Generators

-

Industrial Fans and Blowers

-

High-Speed Pumps

-

Critical Machinery in Oil & Gas Refineries

-

Condition Monitoring in Power Plants

-

Rotating Equipment in Chemical Processing Units

🔗 Compatible Models

The 3500/22-01-02-00 is designed to work seamlessly with the following models within the 3500 series:

-

3500/05 (System Rack)

-

3500/15 (Power Supply Module)

-

3500/20 (Rack Interface Module)

-

3500/25 (Keyphasor Module)

-

3500/40M (Proximitor Monitor)

-

3500/42M (Dynamic Pressure Monitor)

-

3500/50 (Tachometer Module)

-

3500/60 & 3500/61 (Temperature Monitors)

-

System 1 Condition Monitoring Software

🛠️ Installation Instructions

-

Power Down the Rack

Before installation, ensure the 3500 rack is powered off and safe for module insertion. -

Insert into Slot 1

The TDI module must be inserted into Slot 1 of the 3500 rack. This slot is reserved specifically for TDI modules. -

Secure the Module

Align the module with the guide rails and gently push it until the connectors engage. Fasten the front retaining screws. -

Connect Communication Cables

Connect the required Ethernet or Serial communication cables to the rear I/O module. -

Power On and Configure

Power on the rack. Use System 1 software to configure and calibrate the TDI module. -

Verify Diagnostic LEDs

Check that OK, TX/RX, and COMM LEDs indicate proper operation.

🔁 6 Related Models from the Same Series

| Model | Function | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|

| 3500/20 | Rack Interface Module | 24 VDC | 241.3 x 24.4 x 241.3 | 0.65 kg |

| 3500/25 | Keyphasor Module | 24 VDC | 241.3 x 24.4 x 241.3 | 0.68 kg |

| 3500/40M | Proximitor Monitor | 24 VDC | 241.3 x 24.4 x 241.3 | 0.75 kg |

| 3500/42M | Vibration Monitor | 24 VDC | 241.3 x 24.4 x 241.3 | 0.72 kg |

| 3500/50 | Tachometer Module | 24 VDC | 241.3 x 24.4 x 241.3 | 0.66 kg |

| 3500/61 | Temperature Monitor | 24 VDC | 241.3 x 24.4 x 241.3 | 0.69 kg |

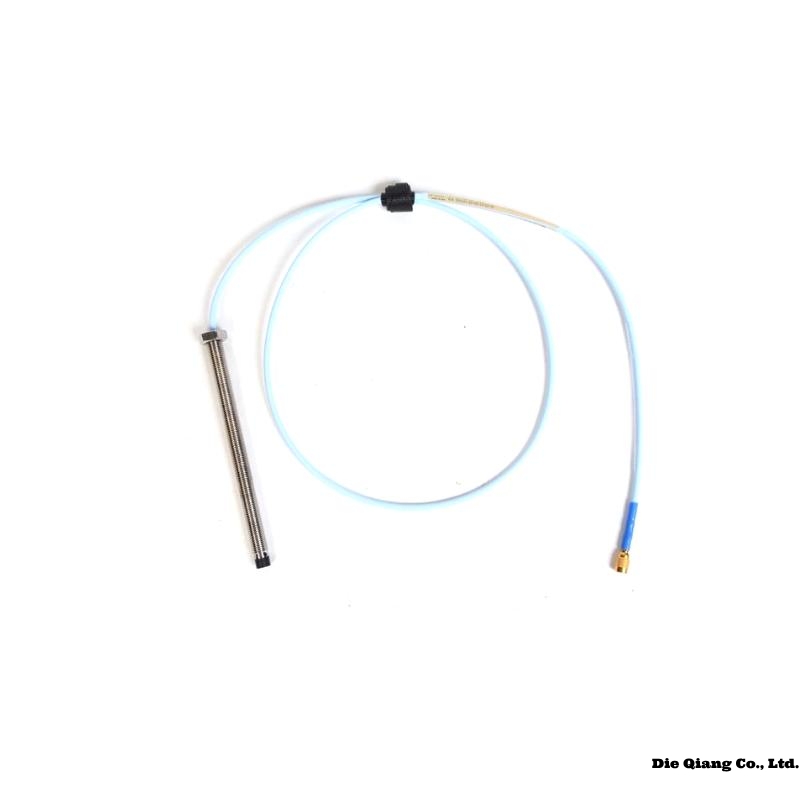

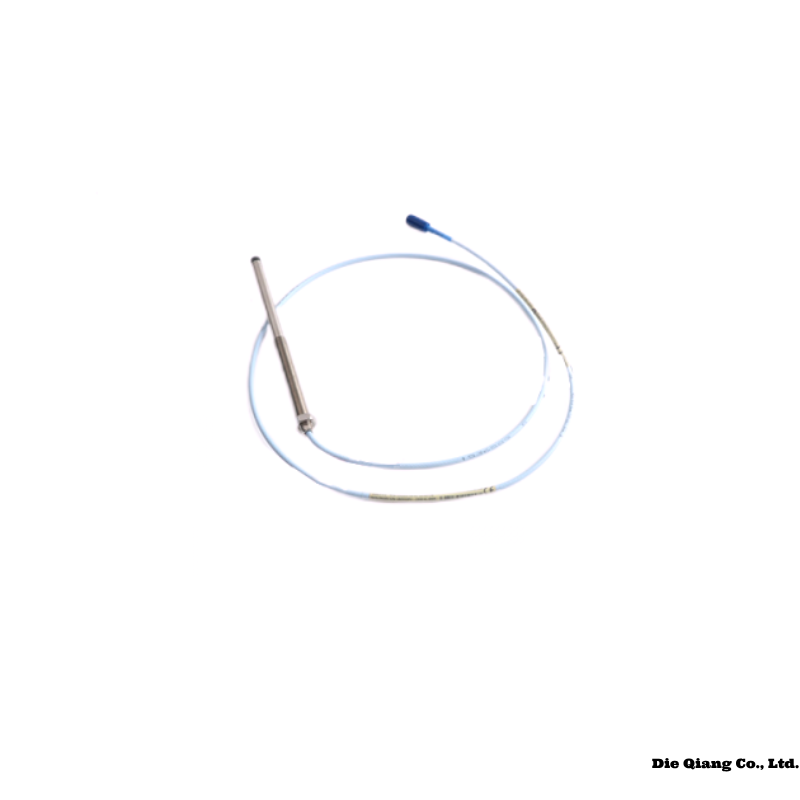

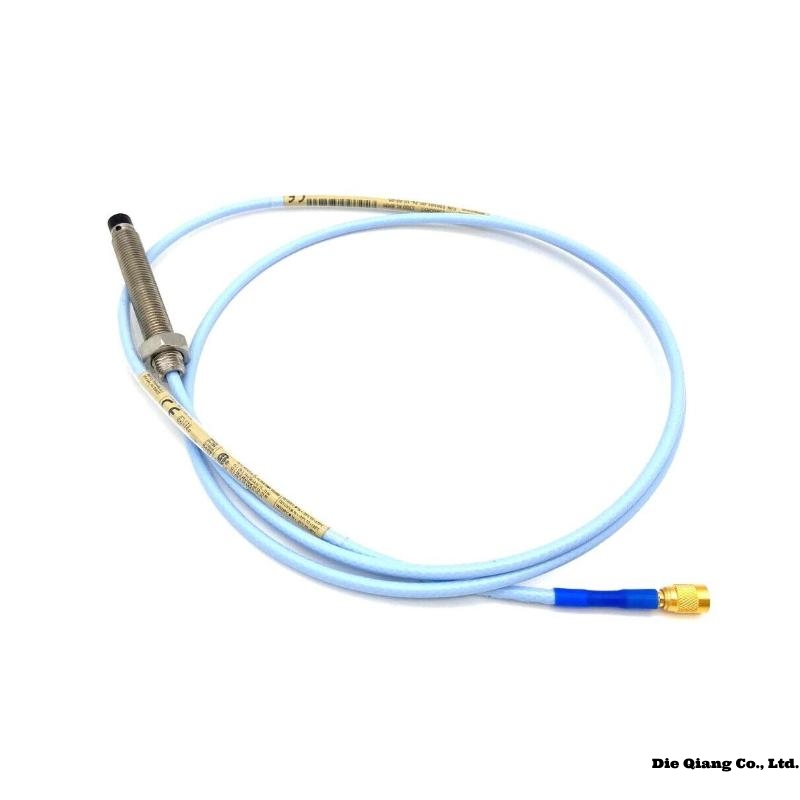

🔝 8 Popular Bently Nevada Models

| Model | Function | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|

| 3300 XL Proximitor | Vibration Sensing Probe | N/A | 76 x 25 x 25 | 0.12 kg |

| 330104-00-05-10-02 | Proximity Probe Extension Cable | N/A | 5m length | 0.15 kg |

| 3500/15 | Power Supply Module | 24 VDC | 241.3 x 24.4 x 241.3 | 0.74 kg |

| 3500/40M | Proximitor Monitor | 24 VDC | 241.3 x 24.4 x 241.3 | 0.75 kg |

| 3500/25 | Keyphasor Module | 24 VDC | 241.3 x 24.4 x 241.3 | 0.68 kg |

| 3500/42M | Vibration Monitor | 24 VDC | 241.3 x 24.4 x 241.3 | 0.72 kg |

| 3500/60 | Temperature Monitor | 24 VDC | 241.3 x 24.4 x 241.3 | 0.69 kg |

| 3701/55 | Vibration Monitor – Overspeed | 24 VDC | 223 x 25 x 150 | 0.70 kg |

❓ Frequently Asked Questions (FAQ)

Q1: What is the function of the 3500/22-01-02-00 module?

A1: The 3500/22-01-02-00 serves as a Transient Data Interface module, enabling high-speed data collection, communication, and configuration of the 3500 system.

Q2: Can the 3500/22-01-02-00 operate in harsh industrial environments?

A2: Yes, it is designed for robust industrial use with a wide operating temperature range and high tolerance to electrical noise.

Q3: Is this module hot-swappable?

A3: No. The module should only be installed or removed when the system is powered off to avoid configuration loss or data corruption.

Q4: How is this module configured after installation?

A4: Configuration is done via System 1 software, which allows firmware updates, channel setup, and communication settings.

Q5: What is the difference between 3500/22 and other modules in the system?

A5: The 3500/22 module specifically handles data communication and integration with host systems, whereas other modules focus on sensing and monitoring.

Q6: What is required to replace a 3500/22-01-02-00 module?

A6: Power down the rack, remove the old module from Slot 1, insert the replacement, and reconfigure it using System 1 software to restore normal operation.

Bently Nevada 3500/22-01-02-00 Transient Data Interface

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||