| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

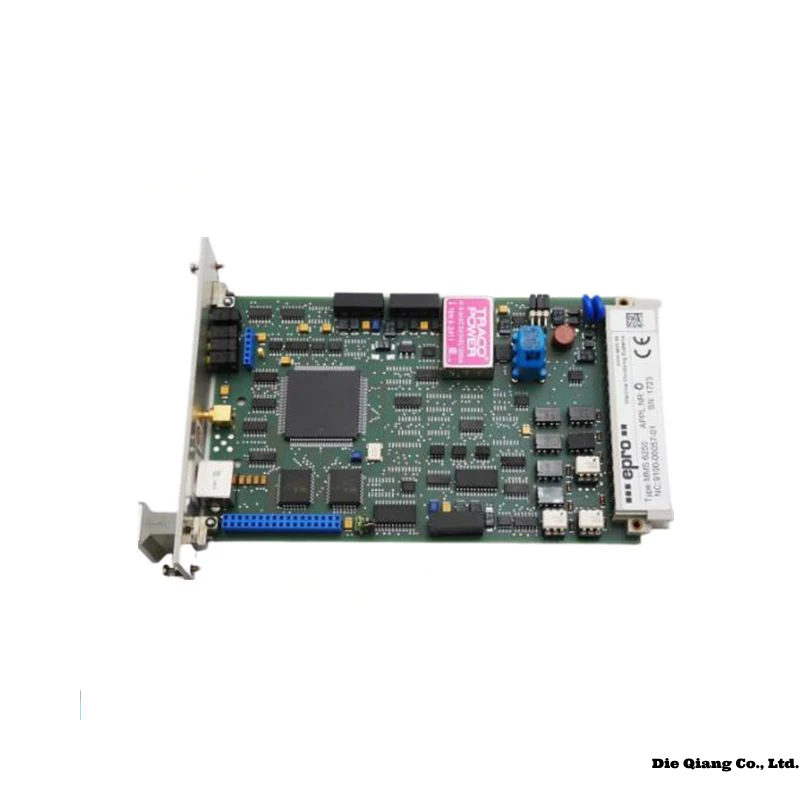

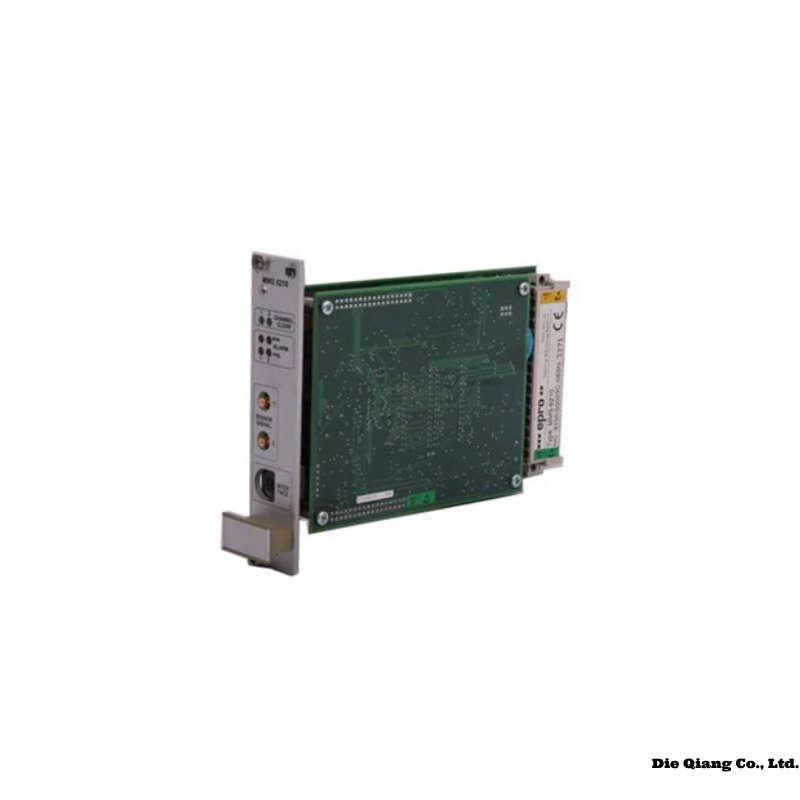

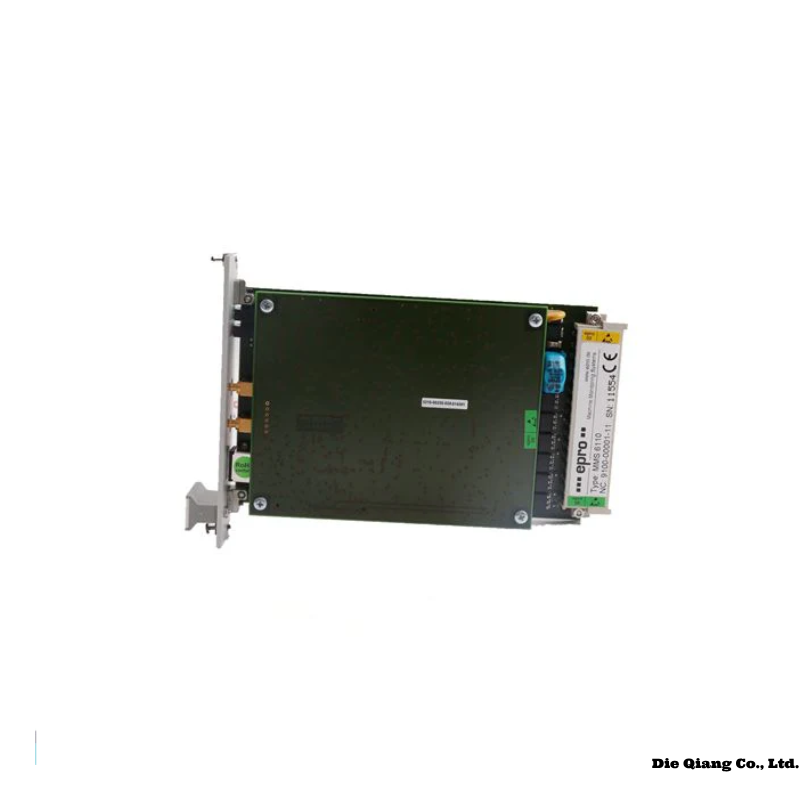

The Epro CON011/916-120+PR6426/010-140 is a highly advanced eddy current sensor designed for precise and reliable measurement of displacement, vibration, and shaft position in industrial applications. This sensor system consists of the PR6426/010-140 probe and the CON011/916-120 converter, offering a robust and highly accurate solution for machinery condition monitoring.

This sensor is specifically engineered to operate in harsh industrial environments, with high resistance to temperature fluctuations, pressure variations, and electromagnetic interference. The 32mm sensing range provides extended measurement capabilities, making it ideal for applications where high accuracy and long-range sensing are required.

The system ensures seamless integration with Epro’s MMS series monitoring systems and other industry-standard condition monitoring platforms. Its advanced signal processing capabilities contribute to enhanced predictive maintenance and operational efficiency.

Technical Specifications

| Parameter | Specification |

|---|---|

| Probe Model | PR6426/010-140 |

| Converter Model | CON011/916-120 |

| Measurement Principle | Eddy Current |

| Sensor Head Diameter | 32mm |

| Output Signal | 4–20mA / 0–10V |

| Operating Temperature | -35°C to +180°C |

| Frequency Response | 0 to 10 kHz |

| Power Supply | 18–30V DC |

| Material | Stainless Steel |

| Protection Class | IP67 |

| Cable Length | 5m / 10m / 15m (customizable) |

| Mounting Thread | M32x1.5 |

| Weight | 1.4 kg |

| Compatibility | MMS 6000 / MMS 3000 / Other CMS Systems |

Product Applications

The Epro CON011/916-120+PR6426/010-140 eddy current sensor is widely used in industries requiring precise displacement and vibration measurement, including:

-

Power Plants: Monitoring turbine shaft position and vibration to prevent failures.

-

Petrochemical Industry: Ensuring safe operation of pumps, compressors, and motors.

-

Aerospace & Aviation: Measuring engine shaft displacement and balancing operations.

-

Manufacturing & Automation: Monitoring spindle movements and alignment in CNC machinery.

-

Steel & Heavy Industries: Condition monitoring of rolling mills, gearboxes, and high-speed rotating machinery.

This sensor is particularly beneficial in predictive maintenance programs, reducing unplanned downtime and extending equipment lifespan.

Product Advantages

-

High Accuracy & Stability: Advanced eddy current sensing technology ensures precise measurement with minimal drift over time.

-

Wide Operating Temperature Range: Can function effectively in extreme industrial environments.

-

Long Sensor Lifespan: Durable stainless-steel construction resists corrosion and mechanical damage.

-

Easy Integration: Compatible with Epro’s MMS series and other leading condition monitoring systems.

-

Customizable Cable Lengths: Allows flexible installation options for different machinery layouts.

-

Fast Response Time: Ideal for real-time monitoring of rotating machinery and high-speed applications.

-

Non-Contact Measurement: Eliminates wear and tear, ensuring long-term reliability.

-

High Resistance to EMI: Can be used in electrically noisy industrial environments without signal interference.

-

Plug-and-Play Installation: Simplifies deployment and reduces setup time.

-

Reduces Maintenance Costs: Helps detect faults early, preventing costly machinery failures.

Compatible Models for Use

This sensor system can be paired with other Epro components to enhance monitoring capabilities:

-

Epro MMS6000 – Advanced condition monitoring system.

-

Epro MMS3000 – Compact vibration monitoring unit.

-

Epro CON021 – Alternative eddy current converter with enhanced signal processing.

-

Epro PR6423/10 – Smaller probe for high-precision applications.

-

Epro PR6425/10 – Medium-range eddy current probe.

Latest News Headlines

-

Epro Expands MMS6000 Series for Enhanced Industrial Monitoring

-

New Eddy Current Sensor Technology Improves Predictive Maintenance

-

Epro Introduces High-Temperature Resistant Vibration Sensors

-

How Epro PR6426 Enhances Machine Reliability in Heavy Industries

-

Advancements in Non-Contact Measurement: The Role of Eddy Current Sensors

Installation Guidelines

-

Mounting the Probe

-

Ensure a clean, dry, and flat surface for sensor installation.

-

Secure the PR6426/010-140 probe using the provided M32x1.5 mounting thread.

-

Adjust the gap distance according to system calibration requirements.

-

-

Connecting the Converter

-

The CON011/916-120 converter should be mounted close to the probe but in a vibration-free area.

-

Use shielded cables to prevent external electrical interference.

-

-

Wiring and Power Supply

-

Connect the system to a 24V DC power supply with proper grounding.

-

Ensure correct wiring polarity to prevent damage.

-

-

System Calibration

-

Perform a zeroing procedure before starting measurements.

-

Use Epro’s diagnostic software for fine-tuning sensor output.

-

-

Final Testing and Validation

-

Run a test cycle to verify signal stability and accuracy.

-

Monitor the system for any unexpected signal fluctuations.

-

Recommended Related Models (Same Series)

| Model | Measurement Range | Probe Diameter | Frequency Response | Operating Temperature |

|---|---|---|---|---|

| PR6426/010-140 + CON011/916-120 | 32mm | 32mm | 0-10 kHz | -35°C to +180°C |

| PR6425/010-130 + CON021 | 25mm | 25mm | 0-8 kHz | -40°C to +150°C |

| PR6423/010-110 + CON011 | 10mm | 10mm | 0-15 kHz | -40°C to +200°C |

| PR6424/010-040 + CON021 | 15mm | 15mm | 0-12 kHz | -35°C to +170°C |

| PR6422/010-030 + CON011 | 5mm | 5mm | 0-20 kHz | -40°C to +220°C |

Recommended Popular Models (Same Brand)

| Model | Application | Measurement Type | Operating Temperature | Output Signal |

|---|---|---|---|---|

| MMS 6312 | Vibration Monitoring | Multi-Channel | -40°C to +85°C | 4–20mA |

| MMS 6350 | Displacement Monitoring | Multi-Channel | -30°C to +100°C | 0-10V |

| PR6423/10 | Shaft Position | Single Channel | -40°C to +200°C | 4–20mA |

| CON021 | Converter | Signal Processing | -35°C to +180°C | 4–20mA |

| MMS 3000 | Compact Monitoring | Multi-Channel | -20°C to +80°C | 0-5V |

FAQ (Frequently Asked Questions)

Q1: What is the primary function of the PR6426/010-140 sensor?

A1: It is used for non-contact measurement of displacement, vibration, and shaft position.

Q2: What is the maximum measurement range of this sensor?

A2: It has a maximum measurement range of 32mm.

Q3: What type of output signal does it provide?

A3: It provides 4–20mA and 0-10V output signals.

Q4: Can this sensor be used in high-temperature environments?

A4: Yes, it operates up to 180°C.

Q5: What industries commonly use this sensor?

A5: Power plants, petrochemical, aerospace, manufacturing, and heavy industries.

Q6: Is the sensor compatible with other monitoring systems?

A6: Yes, it integrates with Epro’s MMS6000, MMS3000, and third-party systems.

Q7: How do I install the sensor correctly?

A7: Ensure proper mounting, correct wiring, and perform system calibration.

Q8: Does the sensor require frequent maintenance?

A8: No, it has a long lifespan with minimal maintenance.

Q9: What protection rating does the sensor have?

A9: It has an IP67 rating for dust and water resistance.

Q10: Can the cable length be customized?

A10: Yes, cable lengths of 5m, 10m, and 15m are available.

Epro CON011/916-120+PR6426/010-140 32mm Eddy Current Sensor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

32mm Eddy Current Sensor, CON011/916-120+PR6426/010-140, Epro, Epro CON011/916-120+PR6426/010-140, PR6426/010-140