| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

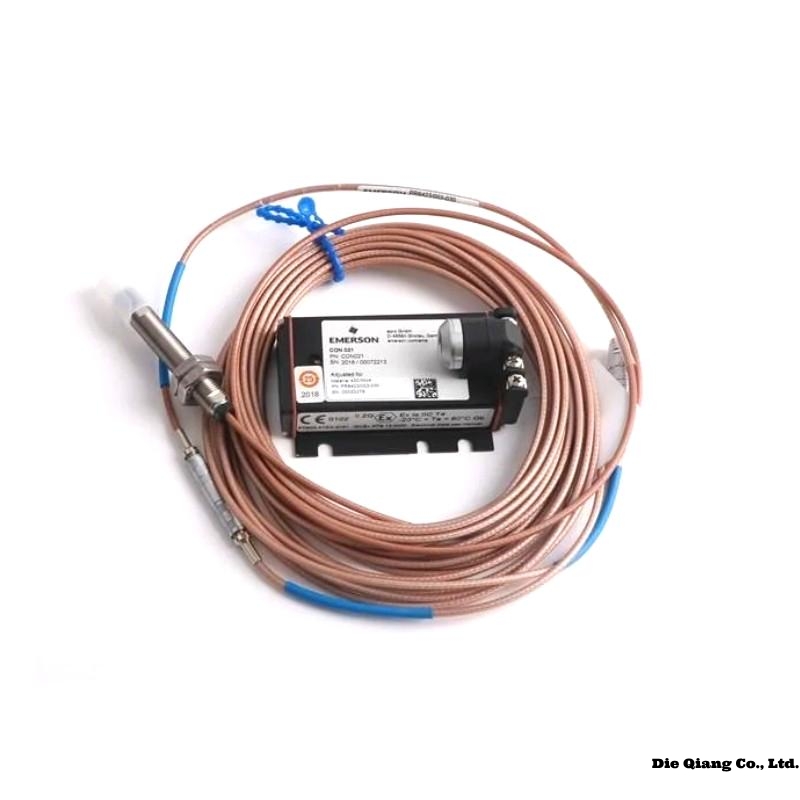

The Epro CON021+PR6423/010-140 is an 8mm eddy current sensor system designed for precise and reliable measurement of shaft vibration and displacement in rotating machinery. This combination includes the PR6423/010-140 eddy current probe and the CON021 converter, ensuring high accuracy and stability in industrial applications. The system is commonly used in turbines, compressors, and other critical rotating equipment for condition monitoring and predictive maintenance.

This sensor system is built with robust materials, making it suitable for harsh industrial environments. It provides a non-contact measurement solution, reducing wear and tear while delivering high precision in dynamic monitoring conditions.

Technical Specifications

| Parameter | Details |

|---|---|

| Probe Model | PR6423/010-140 |

| Converter Model | CON021 |

| Measurement Principle | Eddy Current |

| Sensor Head Diameter | 8mm |

| Measuring Range | 0.25mm – 2.5mm |

| Output Signal | 4-20 mA / 0-10V |

| Frequency Response | 0-10 kHz |

| Temperature Range | -35°C to +180°C |

| Power Supply | +24V DC |

| Cable Length | Standard 5m, extendable up to 10m |

| Material | Stainless Steel / PEEK Insulation |

| Dimensions | Probe: Ø8mm x 50mm |

| Weight | 0.22 kg |

Product Applications

-

Turbines: Used to monitor rotor vibration and displacement in power generation plants.

-

Compressors: Ensures operational safety and efficiency in petrochemical and gas processing facilities.

-

Pumps: Helps detect misalignment and bearing wear in industrial fluid-handling systems.

-

Generators: Used in predictive maintenance for stable power generation.

-

Industrial Fans and Blowers: Monitors rotor balance and shaft displacement to prevent failures.

Product Advantages

High Measurement Accuracy: Provides precise non-contact displacement and vibration measurements.

Robust Design: Constructed from high-quality materials to withstand harsh environments.

Wide Temperature Range: Operates effectively in extreme industrial conditions.

Versatile Output Options: Compatible with different monitoring systems with 4-20mA or voltage output.

Long Cable Compatibility: Supports extended sensor placement up to 10 meters.

Reliable Performance: Ensures long-term stability in critical rotating machinery applications.

Compatible Models for Use with This Product

-

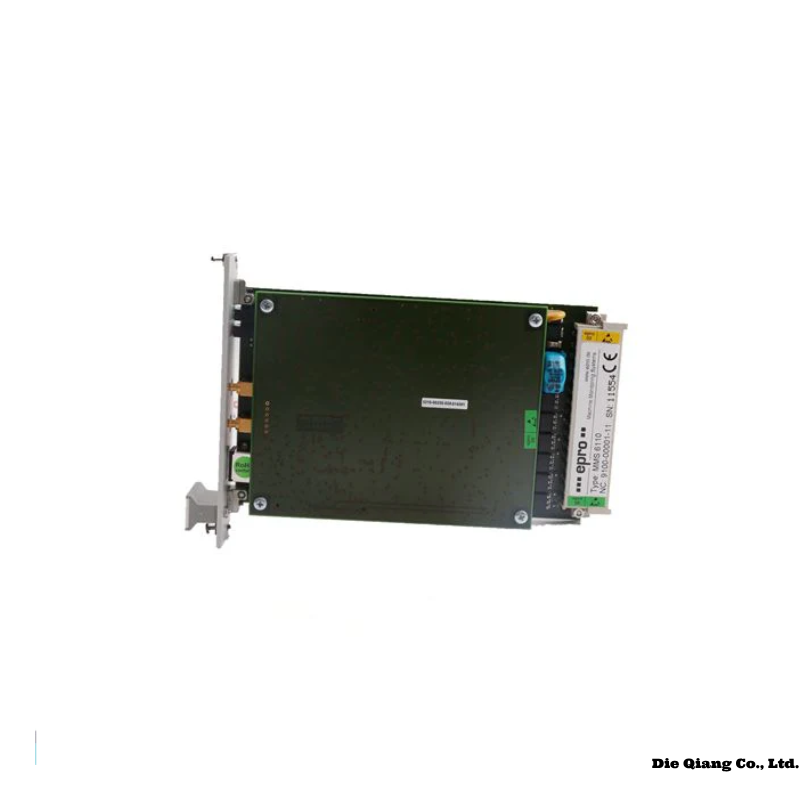

Epro MMS6350 – Vibration monitoring module

-

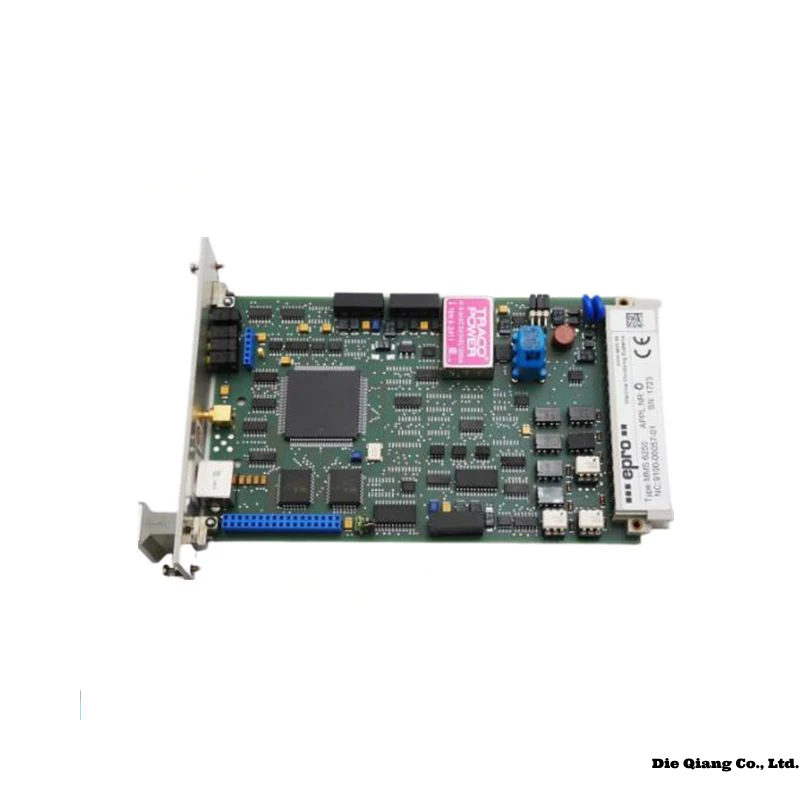

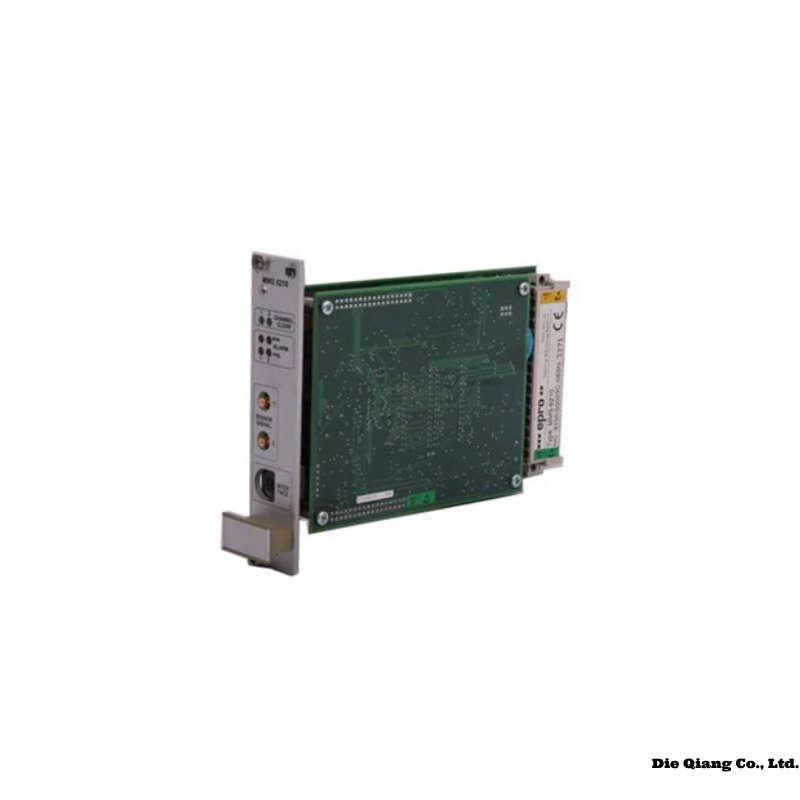

Epro MMS6210 – Signal processing module

-

Epro PR6423/002-030 – Alternative eddy current probe

-

Epro CON011 – Compatible signal converter

-

Epro PR6424/014-040 – Extended range eddy current sensor

Latest News Titles About the Product

-

“Enhancing Rotating Equipment Safety with Epro CON021+PR6423/010-140”

-

“The Role of 8mm Eddy Current Sensors in Predictive Maintenance”

-

“Epro PR6423 Series: Improving Vibration Monitoring in Heavy Industries”

-

“How Non-Contact Sensing Technology is Transforming Industrial Applications”

-

“Best Practices for Installing and Maintaining Eddy Current Sensors”

Installation Instructions

-

Mounting the Probe: Secure the PR6423/010-140 probe in place using the provided mounting bracket, ensuring a proper gap between the probe tip and the rotating surface (typically 1mm).

-

Cable Connection: Connect the probe to the CON021 converter using the standard 5m coaxial cable. If longer distances are required, use an extension cable of up to 10m.

-

Power Supply: Provide a stable +24V DC power source to the CON021 converter.

-

Signal Output Wiring: Connect the output terminals to a data acquisition system, ensuring proper configuration of 4-20mA or voltage output.

-

Calibration & Testing: Adjust sensor positioning and verify measurements using test signals to ensure proper operation before full system deployment.

-

Environmental Protection: Ensure the sensor and converter are properly shielded against environmental contaminants such as dust, oil, and moisture.

Recommended Related Models from the Same Series

| Model | Probe Size | Measuring Range | Output Signal | Temperature Range |

|---|---|---|---|---|

| PR6423/002-030 | 8mm | 0.25mm – 2.5mm | 4-20mA / 0-10V | -35°C to +180°C |

| PR6423/003-010 | 5mm | 0.2mm – 2.0mm | 4-20mA / 0-10V | -40°C to +200°C |

| PR6423/004-010 | 10mm | 0.3mm – 3.0mm | 4-20mA / 0-10V | -30°C to +150°C |

| PR6423/005-010 | 8mm | 0.25mm – 2.5mm | 4-20mA / 0-10V | -40°C to +180°C |

| PR6424/014-040 | 8mm | 0.25mm – 2.5mm | 4-20mA / 0-10V | -35°C to +180°C |

Recommended Popular Models from the Same Brand

| Model | Type | Application | Output Signal |

|---|---|---|---|

| MMS3120/022-100 | Monitoring Module | Vibration monitoring | Digital |

| MMS3125/022-020 | Signal Processing Unit | Data acquisition | Digital |

| MMS6350 | Protection System | Turbine monitoring | Digital |

| PR6422/10 | Eddy Current Sensor | Shaft vibration analysis | 4-20mA / 0-10V |

| CON011 | Converter Unit | Signal conditioning | 4-20mA / 0-10V |

| MMS6210 | Processing Module | Industrial monitoring | Digital |

Frequently Asked Questions (FAQ)

Q1: What is the purpose of the Epro CON021+PR6423/010-140 sensor?

A1: It is used for non-contact measurement of shaft displacement and vibration in rotating machinery.

Q2: What is the measuring range of this sensor?

A2: The measuring range is between 0.25mm and 2.5mm.

Q3: Can the sensor be used in high-temperature environments?

A3: Yes, it operates in temperatures ranging from -35°C to +180°C.

Q4: What is the probe tip diameter?

A4: The probe has a diameter of 8mm.

Q5: What type of output signal does this system provide?

A5: It supports 4-20mA and 0-10V output.

Q6: What is the maximum cable length supported?

A6: The system supports cables up to 10 meters in length.

Q7: Is it compatible with other Epro modules?

A7: Yes, it works with Epro MMS6350, MMS6210, and CON011.

Q8: What is the weight of the probe?

A8: The probe weighs 0.22 kg.

Q9: How is the sensor installed?

A9: It is mounted using a bracket, and the probe should maintain an optimal air gap of 1mm from the target surface.

Q10: Does this sensor require regular maintenance?

A10: It is a low-maintenance device, but periodic inspections for dirt or physical damage are recommended.

Epro CON021+PR6423/010-140 8mm Eddy Current Sensor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||