| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

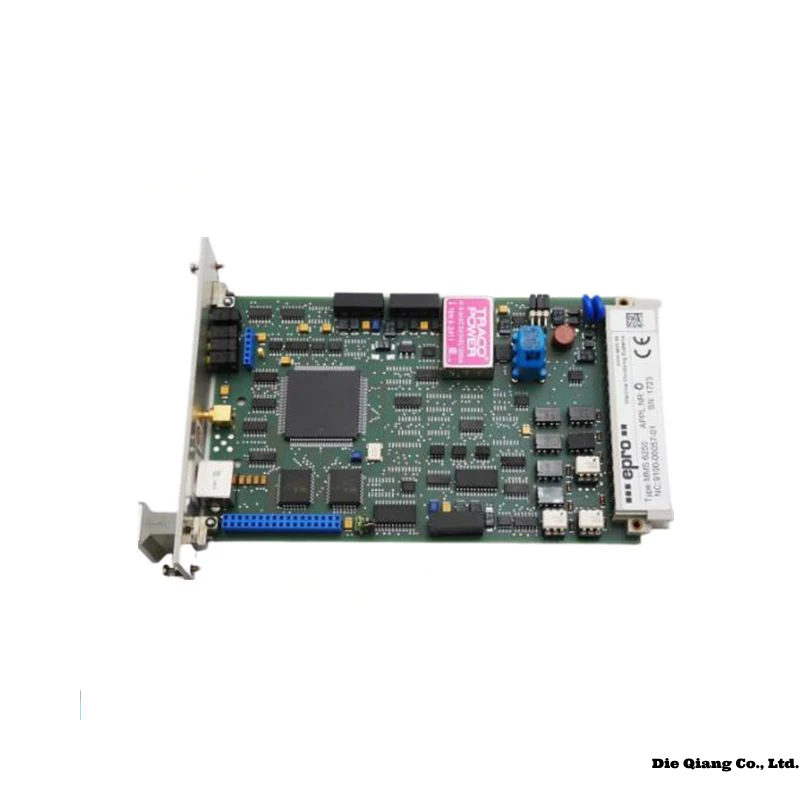

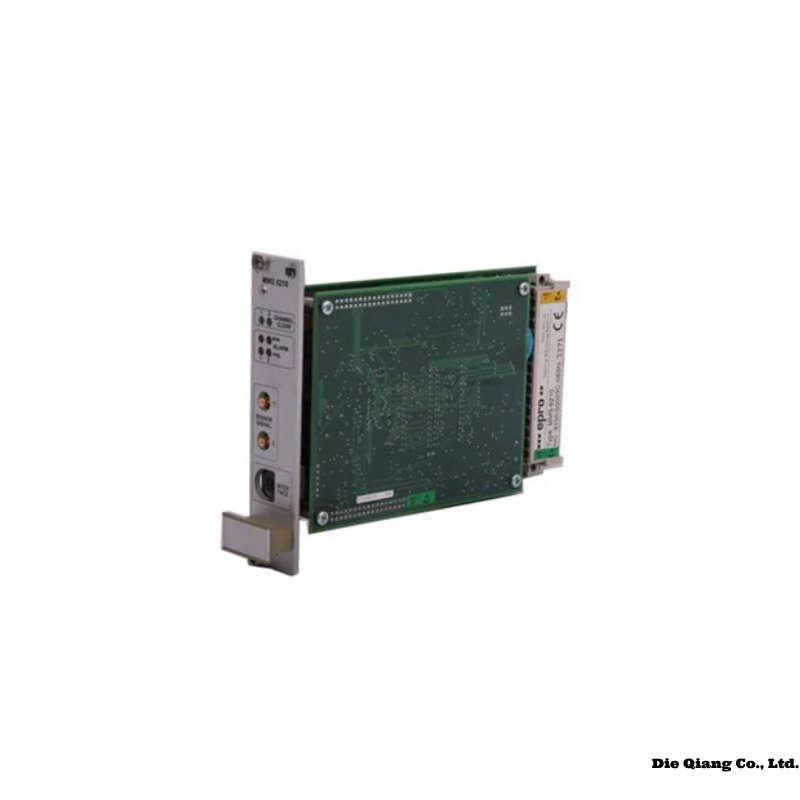

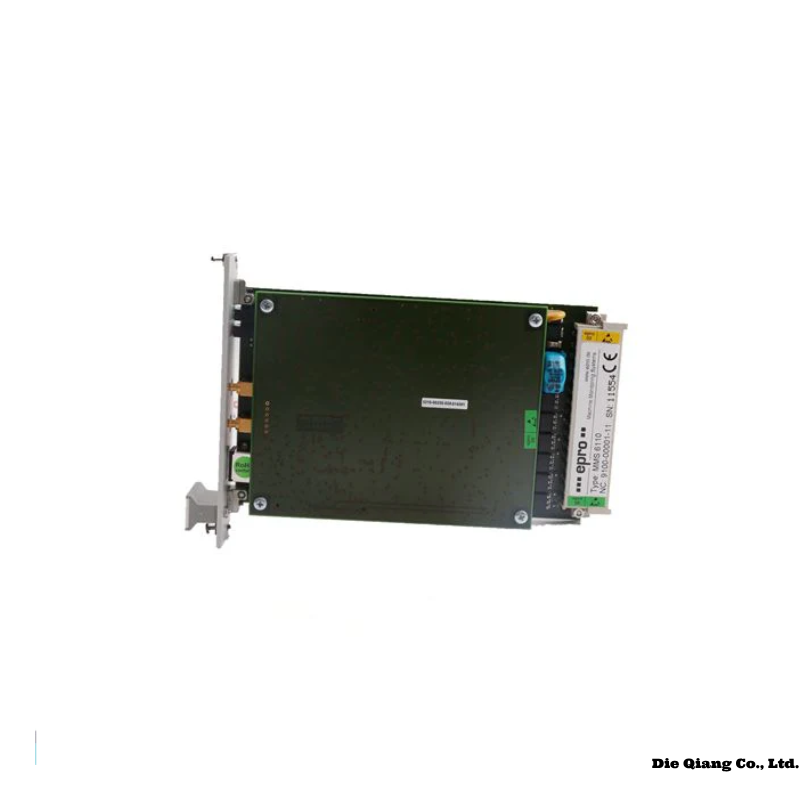

The Epro CON021 + PR6423/015-010 is an industrial-grade eddy current sensor designed for high-precision non-contact displacement and vibration measurement. This sensor system is widely used in critical rotating machinery such as turbines, compressors, pumps, and motors to monitor shaft displacement, vibration levels, and other key parameters.

The PR6423/015-010 probe utilizes eddy current technology to detect changes in the position of conductive materials without physical contact. The CON021 converter processes the raw sensor signal and provides an output compatible with industrial monitoring systems. With a measurement range of 8mm, this system ensures accurate and reliable data acquisition, making it an essential component for predictive maintenance and machine condition monitoring.

Designed for harsh industrial environments, this sensor system offers high durability, temperature resistance, and electromagnetic interference (EMI) immunity. The robust stainless steel housing and flexible cable options make it suitable for various installation scenarios.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Epro CON021 + PR6423/015-010 |

| Measurement Principle | Eddy Current Displacement Sensor |

| Measurement Range | 8mm |

| Nominal Output Signal | -2V to -18V / 4-20mA |

| Linearity Error | ≤1% of Full Scale |

| Frequency Response | 0 to 10kHz |

| Operating Temperature | -35°C to +125°C |

| Probe Thread Size | M10×1 |

| Probe Material | Stainless Steel |

| Cable Length | 5m (Customizable) |

| Connector Type | Coaxial |

| Compatible Converter | CON021 |

| Power Supply | +24V DC |

| Protection Rating | IP67 |

| Sensor Head Diameter | 8mm |

| Weight | 0.22 kg |

Applications

-

Rotating Machinery Condition Monitoring – Used in turbines, compressors, pumps, and motors to measure shaft displacement and vibration.

-

Predictive Maintenance – Prevents unexpected machine failures by providing early warning signs of mechanical issues.

-

Power Plants – Used in gas and steam turbines for real-time performance analysis.

-

Automotive and Aerospace – Helps in testing and R&D for precise vibration analysis.

-

Industrial Manufacturing – Supports machine diagnostics in production lines and heavy equipment.

Advantages

High Accuracy – Ensures precise displacement measurements with minimal error.

Non-Contact Measurement – No mechanical wear, ensuring long-term reliability.

Wide Temperature Range – Operates in extreme industrial conditions.

Electromagnetic Interference (EMI) Resistance – Stable performance in harsh environments.

Compact & Durable Design – Stainless steel housing for enhanced durability.

Customizable Cable Length – Allows flexible installation.

Industry-Standard Compatibility – Seamless integration with industrial monitoring systems.

IP67 Protection Rating – Dustproof and water-resistant for reliable field use.

Compatible Models for System Integration

| Model | Measurement Range | Thread Size | Cable Length | Output Signal | Weight |

|---|---|---|---|---|---|

| PR6423/015-000 | 8mm | M10×1 | 5m | -2V to -18V | 250g |

| PR6423/015-020 | 8mm | M10×1 | 7m | -2V to -18V | 270g |

| PR6423/015-030 | 8mm | M10×1 | 10m | -2V to -18V | 290g |

| PR6423/015-040 | 8mm | M10×1 | 5m | 4-20mA | 250g |

| PR6423/015-050 | 8mm | M10×1 | 7m | 4-20mA | 270g |

Latest Industry News Titles

-

“Epro Eddy Current Sensors Enhancing Industrial Monitoring Precision”

-

“The Future of Predictive Maintenance: Advances in Eddy Current Sensing”

-

“How Epro CON021 + PR6423/015-010 Improves Vibration Analysis in Turbines”

-

“Epro’s Latest Developments in Machine Condition Monitoring”

-

“Industrial Sensors: Innovations in Non-Contact Displacement Measurement”

Installation Instructions

-

Prepare the Components – Ensure you have the PR6423/015-010 probe, CON021 converter, and necessary cabling.

-

Mount the Probe – Securely attach the probe to the desired location using the M10×1 threaded mount.

-

Positioning – Maintain an optimal gap between the sensor and the target surface for accurate measurement.

-

Cable Routing – Properly secure the coaxial cable, avoiding sharp bends and excessive tension.

-

Connect to Converter – Attach the probe cable to the CON021 signal converter securely.

-

Power Supply – Provide a +24V DC power source to the converter.

-

Signal Calibration – Adjust settings according to system requirements for precise measurement.

-

Testing & Validation – Conduct operational tests and verify signal accuracy before finalizing installation.

Popular Models from the Same Brand (Epro)

| Model | Function | Measurement Range | Output Signal | Weight |

|---|---|---|---|---|

| MMS3120/022-100 | Vibration Monitoring Module | 8mm | 4-20mA | 500g |

| MMS6120/021-000 | Displacement Monitoring | 12mm | -2V to -18V | 480g |

| MMS6350 | Speed Sensor Module | 14mm | Digital Output | 520g |

| MMS6410 | Multi-Channel Monitor | 12mm | Analog Output | 530g |

| PR6424/014-040 | High-Temp Eddy Current Probe | 14mm | -2V to -18V | 370g |

| CON011 | Signal Converter | 9mm | 4-20mA | 400g |

FAQ for Epro CON021 + PR6423/015-010 8mm Eddy Current Sensor

Q1: What is the primary function of the Epro CON021 + PR6423/015-010 sensor?

A1: The Epro CON021 + PR6423/015-010 is an eddy current displacement sensor designed for non-contact measurement of shaft displacement, vibration, and position in rotating machinery. It is widely used in industrial applications, including turbines, compressors, motors, and pumps, to ensure machine reliability and efficiency.

Q2: How does the eddy current measurement principle work in this sensor?

A2: The sensor operates based on the eddy current principle, where an alternating current is induced in the probe coil, creating an electromagnetic field. When a conductive target (such as a metal shaft) is within range, eddy currents are generated on its surface, altering the electromagnetic field. This change is detected and converted into a displacement or vibration signal, providing high-accuracy measurement without physical contact.

Q3: What is the measurement range of the PR6423/015-010 probe?

A3: The PR6423/015-010 probe has a measurement range of 8mm, allowing precise monitoring of shaft movement within this distance. The range is carefully designed to balance sensitivity and stability for industrial applications.

Q4: What are the output signal options for this sensor system?

A4: The Epro CON021 + PR6423/015-010 sensor provides two types of output signals:

-

Voltage Output: -2V to -18V

-

Current Output: 4-20mA

These outputs ensure compatibility with various industrial monitoring systems and programmable logic controllers (PLCs).

Q5: What environmental conditions can the sensor withstand?

A5: This sensor is built for harsh industrial environments. It operates reliably in temperatures ranging from -35°C to +125°C and features an IP67-rated stainless steel probe, making it resistant to dust, moisture, and oil contamination. Its design ensures stable performance even in high-vibration and electromagnetically noisy environments.

Q6: How should the sensor be installed for optimal performance?

A6: Proper installation is essential for accurate measurement:

-

Mounting: The probe should be securely attached using the M10×1 threaded mount and positioned perpendicular to the target surface.

-

Gap Adjustment: The sensor should be calibrated to maintain an optimal gap between 0.5mm and 8mm for best results.

-

Cable Management: The coaxial cable should be routed properly, avoiding sharp bends and mechanical stress to ensure signal integrity.

-

Connection: The probe must be connected to the CON021 converter, which processes the signal for output.

-

Power Supply: A stable +24V DC power source should be provided to the converter for consistent performance.

Q7: What makes this sensor ideal for predictive maintenance?

A7: Predictive maintenance relies on continuous monitoring and early fault detection. The Epro CON021 + PR6423/015-010 sensor helps detect:

-

Shaft misalignment

-

Bearing wear

-

Unbalance and excessive vibration

-

Thermal expansion effects

By providing real-time, high-precision displacement and vibration data, this sensor enables engineers to predict equipment failures and perform maintenance before catastrophic damage occurs, reducing downtime and operational costs.

Q8: What industries commonly use this sensor?

A8: The Epro CON021 + PR6423/015-010 is extensively used in industries that require high-precision vibration and displacement monitoring, including:

-

Power Generation: Steam and gas turbines in power plants.

-

Oil & Gas: Compressors and pumps in refineries.

-

Aerospace & Automotive: Testing and development of engines and rotating components.

-

Manufacturing: Heavy machinery and conveyor system monitoring.

-

Steel & Paper Mills: Large rotating equipment condition monitoring.

Q9: Can the PR6423/015-010 probe be used with other converters apart from CON021?

A9: While the CON021 is the recommended signal converter for this probe, the PR6423/015-010 may also be compatible with other Epro converters such as CON011, provided they support the same signal processing requirements. However, for optimal accuracy and performance, it is best used with the CON021, which is specifically designed for this sensor type.

Q10: What maintenance is required for this sensor system?

A10: The Epro CON021 + PR6423/015-010 sensor requires minimal maintenance but should be regularly checked for:

-

Probe Condition: Ensure no physical damage or contamination on the probe tip.

-

Cable Integrity: Inspect for any bends, cuts, or loose connections in the coaxial cable.

-

Signal Consistency: Periodically verify the sensor output against a reference to confirm measurement accuracy.

-

Environmental Factors: Make sure the sensor is free from excessive dust, oil, or debris that could affect readings.

-

Software Calibration: If integrated into a monitoring system, ensure that calibration settings are properly maintained for accurate data interpretation.

Epro CON021+PR6423/015-010 8mm Eddy Current Sensor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||