| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

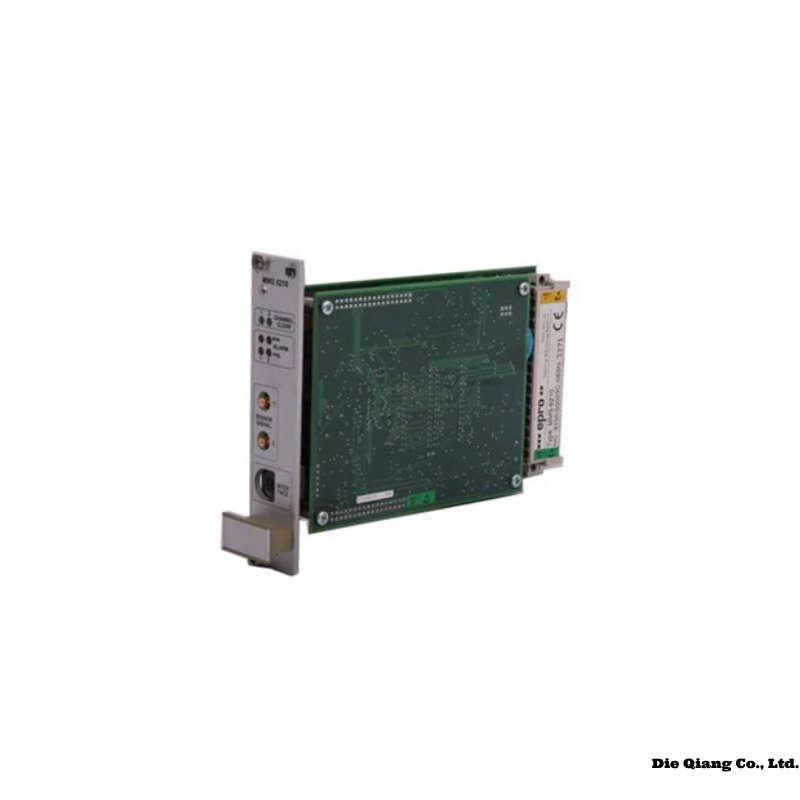

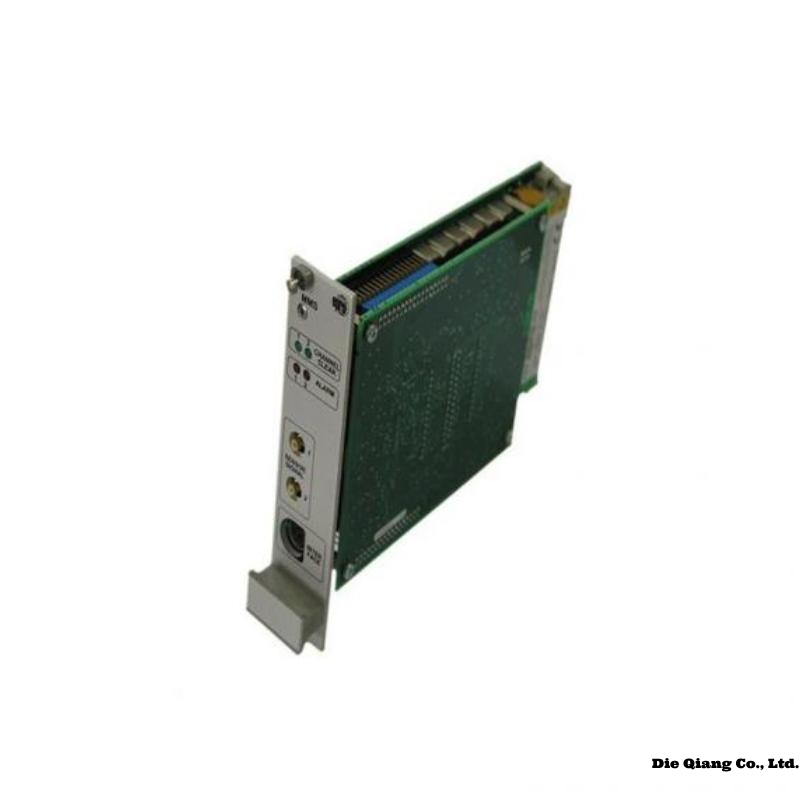

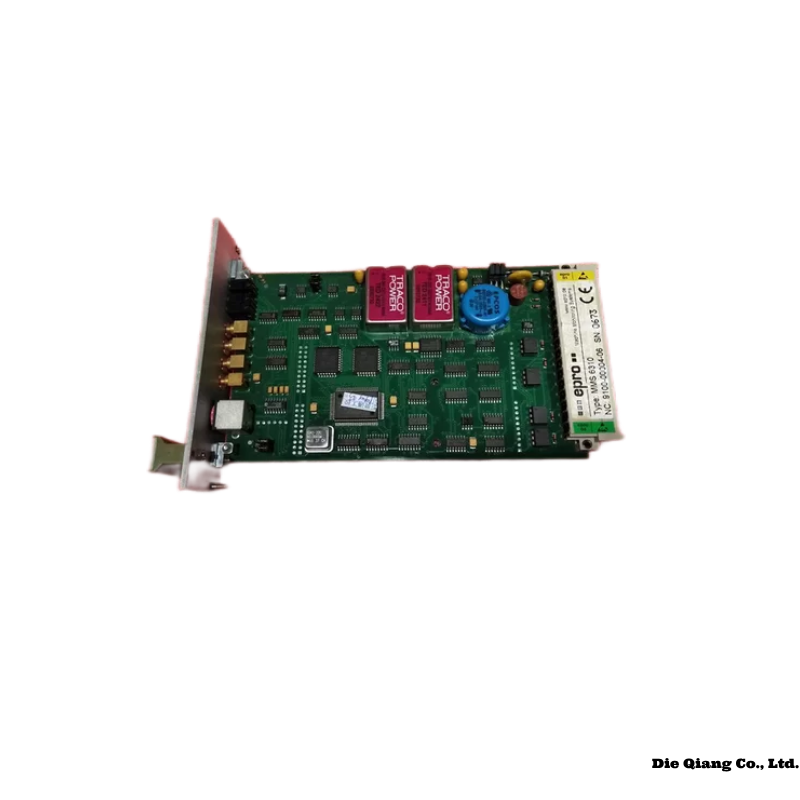

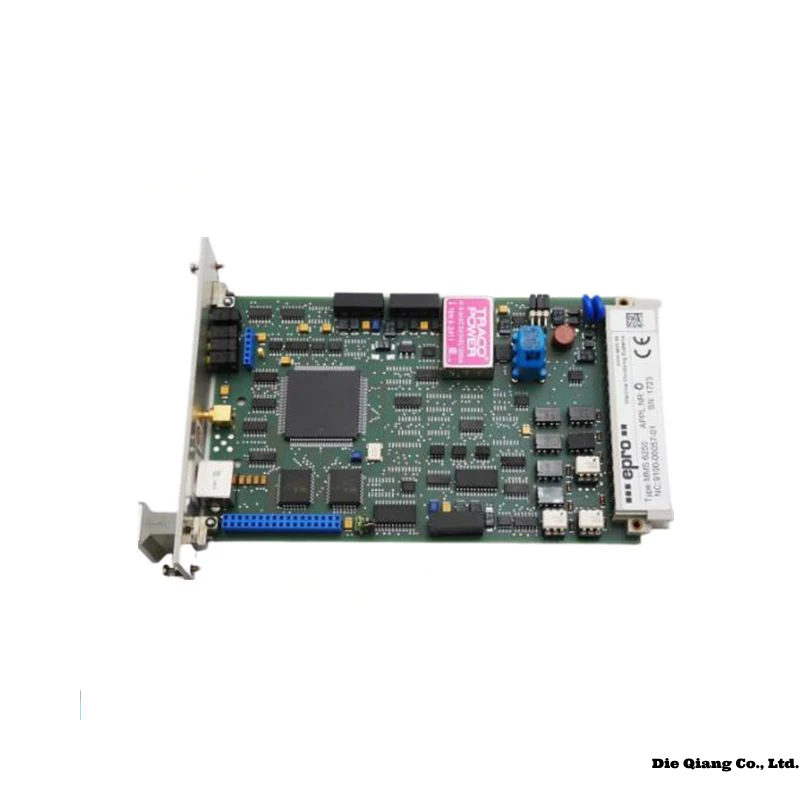

Product Introduction: Epro MMS6120

The Epro MMS6120 is a high-precision condition monitoring module engineered for critical industrial applications. Designed to integrate seamlessly with rotating machinery, the MMS6120 offers robust real-time vibration analysis and monitoring, helping to prevent equipment failure and optimize maintenance strategies. It forms a part of the renowned Epro condition monitoring system, which is known for its reliability and modular scalability.

This module is used to detect early signs of mechanical faults such as imbalance, misalignment, and bearing wear in rotating machinery. It is ideally suited for turbines, compressors, pumps, and motors in power generation, petrochemical, and process industries.

Product Advantages

-

High Accuracy: Offers precise vibration monitoring for early fault detection and diagnostics.

-

Modular Design: Easily integrates with other Epro monitoring modules, allowing flexible system configuration.

-

Industrial Durability: Built for harsh industrial environments, with high resistance to temperature, dust, and vibration.

-

Real-time Monitoring: Provides continuous data acquisition and fault detection to support predictive maintenance.

-

Compatibility: Seamlessly interfaces with existing Epro systems and other industry-standard monitoring platforms.

-

Reduced Downtime: Helps in proactive maintenance planning, thereby reducing unexpected failures and unplanned outages.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | MMS6120 |

| Dimensions | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

| Supply Voltage | 24 V DC (typical) |

| Input Signal | Vibration sensor input (accelerometer or velocity) |

| Signal Range | ±10 V |

| Frequency Range | 10 Hz to 10 kHz |

| Output | Analog and Digital |

| Mounting Type | DIN Rail or Rack Mountable |

| Operating Temperature | -20°C to +65°C |

| Protection Class | IP20 (modular housing) |

| Communication | RS-485 / Modbus / Proprietary protocol |

Applications

-

Power Plants – For turbine and generator condition monitoring.

-

Petrochemical Plants – Monitor compressors, pumps, and fans.

-

Steel Industry – Applied in motor and gearbox monitoring.

-

Paper Mills – For consistent monitoring of rotating equipment.

-

Marine Engineering – Engine and propulsion system monitoring.

-

Pharmaceutical Manufacturing – Precision equipment diagnostics.

Compatible and Supporting Models

The Epro MMS6120 works in tandem with the following components:

-

Epro PR6423 – Eddy current proximity sensor for shaft vibration.

-

Epro CON021 – Sensor signal converter, works with PR6423.

-

Epro MMS3110 – Rack-based processor unit for signal integration.

-

Epro MMS6410 – Extension module for multi-channel monitoring.

-

Epro MMS6121 – Extended function module with advanced DSP.

-

Epro TQ402 – Tachometer module for speed input synchronization.

Installation Guide

-

Mounting: The MMS6120 module is mounted on a DIN rail or inserted into a compatible rack enclosure (e.g., MMS6000 rack system). Ensure proper grounding to reduce noise interference.

-

Sensor Connection: Connect vibration sensors (e.g., PR6423) to the input terminal. Use shielded cables to avoid EMI/RFI.

-

Power Supply: Supply the module with 24 V DC using the recommended industrial-grade power supply.

-

System Integration: Use RS-485 or other standard interfaces to connect to the central monitoring system or SCADA.

-

Configuration: Use Epro software tools for initial setup, channel configuration, and alarm threshold definitions.

-

Testing and Commissioning: After installation, perform loop checks and simulate sensor signals to verify proper functioning.

Related Models (Same Series or Functionality)

-

Epro MMS6121 – Advanced variant with digital filtering.

-

Epro MMS6410 – Expansion unit for multi-point measurements.

-

Epro MMS3110 – Central processor module for signal aggregation.

-

Epro MMS6312 – Multi-signal module for velocity and displacement.

-

Epro MMS8020 – Monitoring system for low-frequency machinery.

-

Epro MMS2040 – Single-channel compact monitoring unit.

Popular Models from Epro (With Specifications)

| Model | Description | Dimensions (mm) | Weight (g) | Voltage | Application |

|---|---|---|---|---|---|

| MMS6120 | Vibration monitoring module | 130 x 100 x 25 | 350 | 24 V DC | General rotating equipment |

| MMS6121 | Advanced vibration analysis module | 130 x 100 x 25 | 360 | 24 V DC | Advanced diagnostics |

| PR6423 | Eddy current vibration sensor | 60 x 20 x 20 | 180 | Passive | Shaft vibration detection |

| CON021 | Signal converter for PR6423 | 90 x 40 x 20 | 200 | 24 V DC | Sensor signal conditioning |

| MMS6410 | Expansion module | 130 x 100 x 25 | 380 | 24 V DC | Channel extension |

| TQ402 | Tachometer module | 100 x 80 x 20 | 250 | 24 V DC | Rotational speed monitoring |

| MMS3110 | Central processing unit | 150 x 120 x 30 | 450 | 24 V DC | Signal processing and analysis |

| MMS2040 | Compact single-channel monitor | 100 x 60 x 20 | 270 | 24 V DC | Portable/standalone monitoring |

FAQ (Frequently Asked Questions)

Q1: What type of sensors are compatible with the MMS6120?

A1: The MMS6120 is compatible with various vibration sensors including Epro PR6423 (eddy current sensors), as well as standard velocity and accelerometer sensors, making it highly versatile.

Q2: Can the MMS6120 be used in high-temperature environments?

A2: The operating temperature range is -20°C to +65°C. For higher temperatures, remote sensor mounting and extended cables are recommended.

Q3: Is this module suitable for standalone operation?

A3: No, the MMS6120 is designed to be part of a larger Epro system. It requires integration with a central processing unit like MMS3110 for full functionality.

Q4: How does the MMS6120 help with maintenance?

A4: By continuously monitoring machinery vibration and detecting anomalies early, the module supports predictive maintenance and reduces unplanned downtime.

Q5: Can I connect this to a SCADA system?

A5: Yes, the MMS6120 supports industrial communication protocols such as RS-485 and Modbus, enabling integration with SCADA or DCS platforms.

Q6: Does the MMS6120 support alarm outputs?

A6: Yes, it features configurable alarm thresholds with both analog and digital outputs for alerting operators to abnormal conditions.

Epro MMS6120 Dual Channel Bearing Vibration Monitor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||