| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

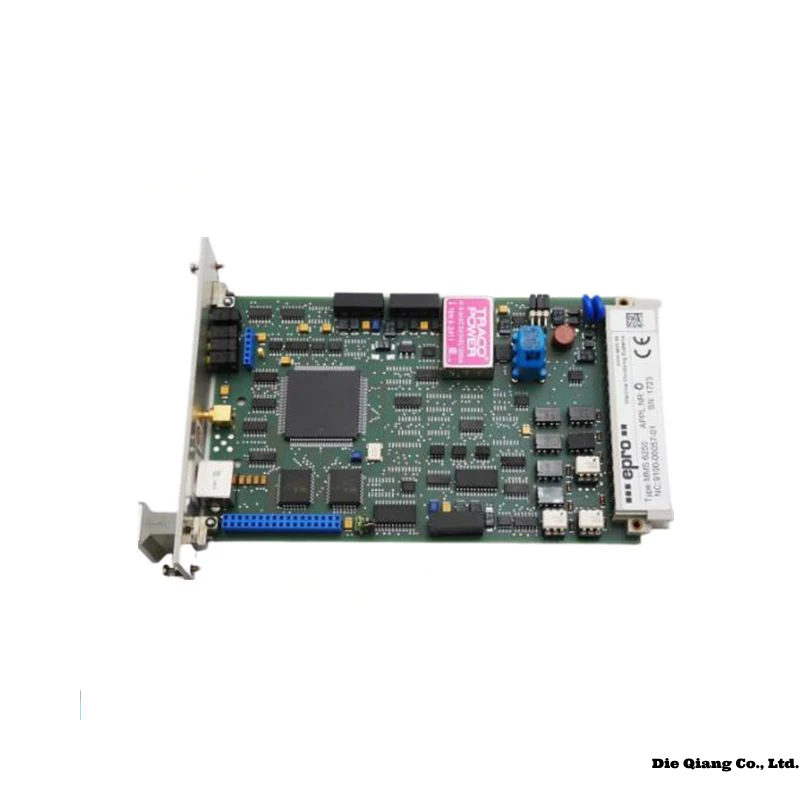

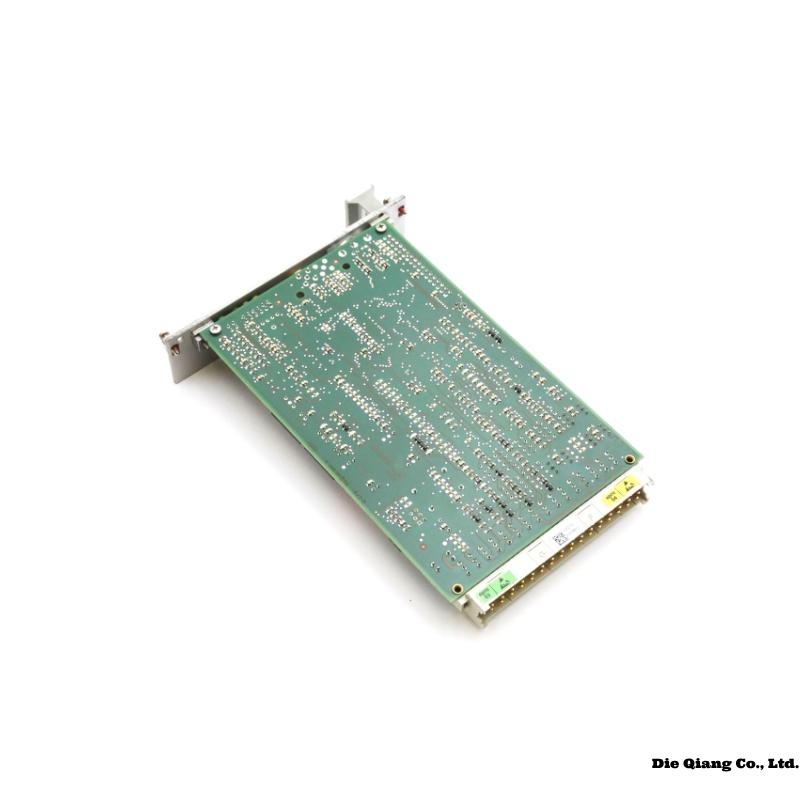

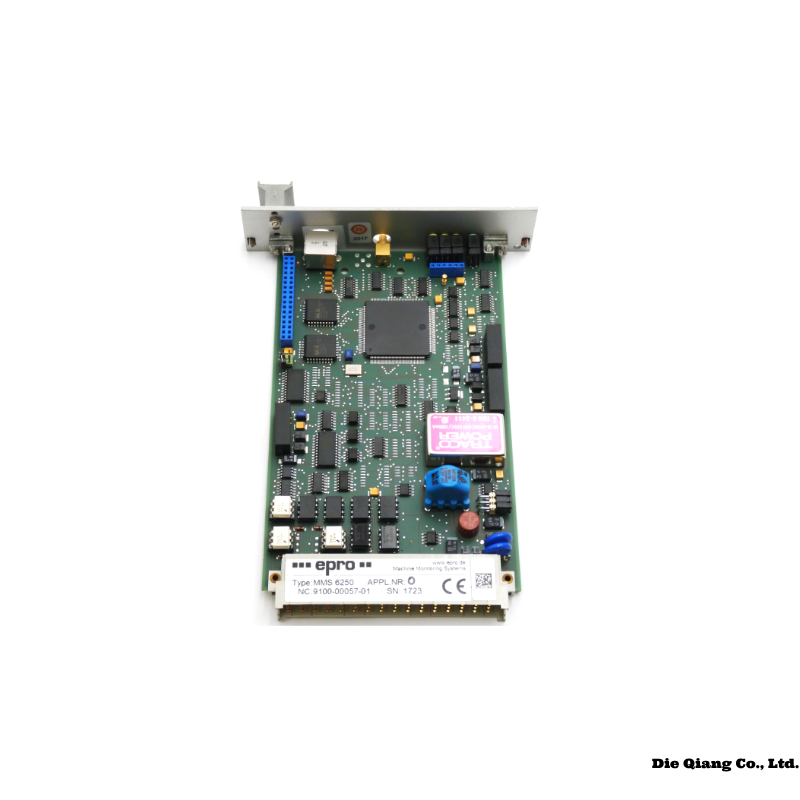

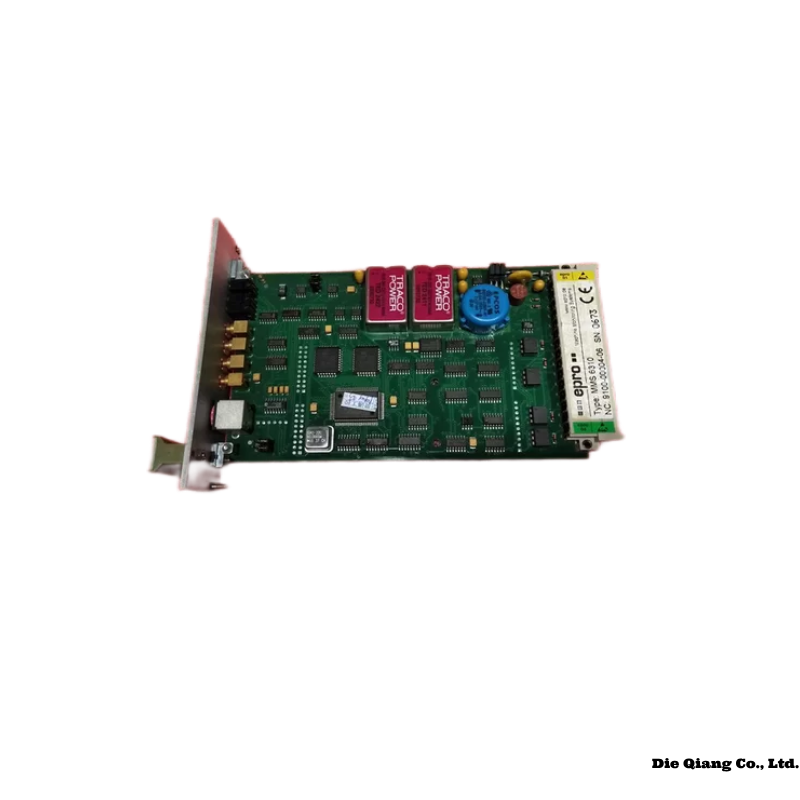

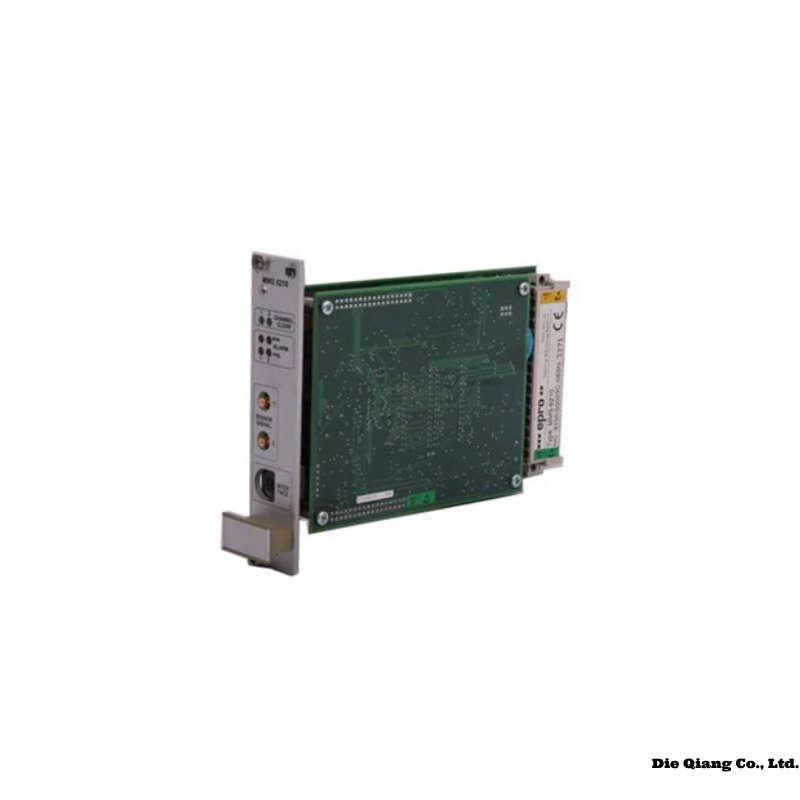

Epro MMS6250 9100-00057 – Comprehensive Product Overview

Product Introduction

The Epro MMS6250 9100-00057 is an advanced machinery monitoring module designed to deliver high-precision vibration monitoring and diagnostics for rotating equipment in industrial applications. Manufactured by Epro, a trusted name in condition monitoring solutions, the MMS6250 forms an integral part of predictive maintenance systems, helping to prevent unscheduled downtimes, extend equipment life, and optimize operational efficiency.

Specifically engineered to interface seamlessly with a variety of transducers and signal conditioners, this model offers exceptional accuracy and reliability in harsh industrial environments. It is widely deployed in sectors such as power generation, petrochemical refining, oil & gas, and heavy machinery manufacturing.

The robust design, high measurement accuracy, and versatile connectivity make the MMS6250 9100-00057 a preferred choice for professionals looking to maintain peak operational conditions of critical machinery assets.

Product Advantages

-

High Measurement Precision: Delivers accurate vibration and position monitoring, enabling early fault detection.

-

Wide Compatibility: Supports various Epro transducers and integrates easily into existing monitoring systems.

-

Durable Industrial Design: Built to operate reliably under extreme temperatures, humidity, and mechanical stress.

-

Real-time Diagnostics: Offers instant monitoring feedback for timely maintenance actions.

-

Reduced Downtime: Enhances predictive maintenance strategies, reducing unplanned shutdowns and maintenance costs.

-

User-friendly Interface: Simplified installation and configuration process with clear diagnostic outputs.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | MMS6250 9100-00057 |

| Manufacturer | Epro |

| Measurement Type | Vibration and Position Monitoring |

| Input Voltage | 24 V DC (Nominal) |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Dimensions | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

| Frequency Range | 0.5 Hz to 20 kHz |

| Output | 4-20 mA / Digital Interface |

| Signal Inputs | Supports proximity probes, velocity sensors, accelerometers |

| Protection Rating | IP65 |

| Mounting Type | DIN Rail Mounting |

| Certifications | CE, RoHS, ATEX compliant |

Product Applications

-

Power Generation Plants: Monitoring turbines, generators, and critical rotating assets.

-

Oil & Gas Industry: Ensuring safe operation of compressors and pumps.

-

Chemical and Petrochemical Facilities: Protecting reactors, agitators, and high-speed machinery.

-

Pulp and Paper Industry: Monitoring rollers and mechanical drives.

-

Steel and Metal Processing: Observing vibration patterns in rolling mills and conveyors.

-

General Manufacturing: Versatile use in various mechanical processing units.

Compatible Models

-

Epro PR6423 – Proximity Probe for precise shaft vibration measurement.

-

Epro CON011 – Connection module for sensor interface.

-

Epro MMS6110 – Monitoring module for additional parameter integration.

-

Epro MMS6300 – Advanced vibration monitoring module.

-

Epro PR9268 – Vibration velocity sensor.

-

Epro CON021 – Signal conditioning unit for enhanced signal processing.

Installation Instructions

-

Preparation:

Ensure the power supply is disconnected before installation. Verify that the installation environment is free of conductive dust and excessive moisture. -

Mounting:

Secure the MMS6250 onto a DIN rail in the control cabinet, ensuring stable and vibration-free placement. -

Wiring:

Connect input signals from compatible sensors (e.g., PR6423) to the designated terminals. Follow the wiring diagram provided in the installation manual. -

Power Supply:

Connect the 24 V DC power supply to the input terminals, ensuring correct polarity to prevent damage. -

Configuration:

Use the configuration interface to set measurement parameters and output ranges. Calibration is recommended during initial setup. -

Testing:

After installation, perform a functional test to confirm that all input signals are properly received and processed. -

Commissioning:

Upon successful testing, the system is ready for operational use. Periodic maintenance and system diagnostics are recommended.

Recommended Related Models (Same Series or Related)

| Model Number | Measurement Type | Voltage | Dimensions (mm) | Weight (g) | Frequency Range |

|---|---|---|---|---|---|

| Epro MMS6110 | Vibration Monitoring | 24 V DC | 110 x 90 x 40 | 420 | 0.5 Hz – 15 kHz |

| Epro MMS6300 | Advanced Vibration Module | 24 V DC | 115 x 92 x 45 | 460 | 0.5 Hz – 20 kHz |

| Epro MMS6350 | Multi-channel Monitoring | 24 V DC | 120 x 95 x 48 | 480 | 0.5 Hz – 20 kHz |

| Epro CON011 | Connection Module | N/A | 100 x 80 x 35 | 300 | N/A |

| Epro PR6423 | Proximity Probe | N/A | 50 x 10 (probe size) | 150 | DC – 10 kHz |

| Epro PR9268 | Vibration Velocity Sensor | N/A | 80 x 30 x 30 | 350 | 2 Hz – 1 kHz |

Popular Epro Models (Highly Recommended)

| Model Number | Description | Voltage | Dimensions (mm) | Weight (g) | Frequency Range |

|---|---|---|---|---|---|

| Epro MMS6250 | Vibration Monitoring Module | 24 V DC | 110 x 90 x 40 | 450 | 0.5 Hz – 20 kHz |

| Epro MMS6110 | Basic Vibration Monitoring | 24 V DC | 110 x 90 x 40 | 420 | 0.5 Hz – 15 kHz |

| Epro MMS6300 | Advanced Monitoring Module | 24 V DC | 115 x 92 x 45 | 460 | 0.5 Hz – 20 kHz |

| Epro CON011 | Sensor Connection Module | N/A | 100 x 80 x 35 | 300 | N/A |

| Epro PR6423 | Shaft Vibration Probe | N/A | 50 x 10 (probe size) | 150 | DC – 10 kHz |

| Epro PR9268 | Velocity Sensor | N/A | 80 x 30 x 30 | 350 | 2 Hz – 1 kHz |

| Epro CON021 | Signal Conditioner | N/A | 120 x 85 x 40 | 310 | N/A |

| Epro PR9266 | High Sensitivity Velocity Sensor | N/A | 85 x 32 x 32 | 360 | 2 Hz – 2 kHz |

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the Epro MMS6250 9100-00057?

A1: The MMS6250 is designed for high-accuracy monitoring of vibration and shaft position in rotating machinery, helping to detect mechanical issues early and prevent equipment failures.

Q2: Can the MMS6250 operate in extreme environmental conditions?

A2: Yes, the module is engineered to perform reliably under a wide temperature range of -20°C to +70°C and has a high protection rating of IP65.

Q3: What types of sensors are compatible with this module?

A3: The MMS6250 supports various Epro sensors, including proximity probes, velocity sensors, and accelerometers, ensuring flexibility for different monitoring needs.

Q4: Is special software required for configuration?

A4: Basic configuration can be done via the onboard interface, but for advanced diagnostics and parameter setting, Epro’s dedicated configuration software is recommended.

Q5: How often should the MMS6250 be calibrated?

A5: It is advisable to calibrate the unit annually or after any significant maintenance operation to maintain measurement accuracy.

Q6: Does the MMS6250 support integration with existing monitoring systems?

A6: Absolutely, the module is designed for seamless integration with existing monitoring and control systems, using standard industrial communication protocols.

Epro MMS6250 9100-00057 Machine monitoring system

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||