| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

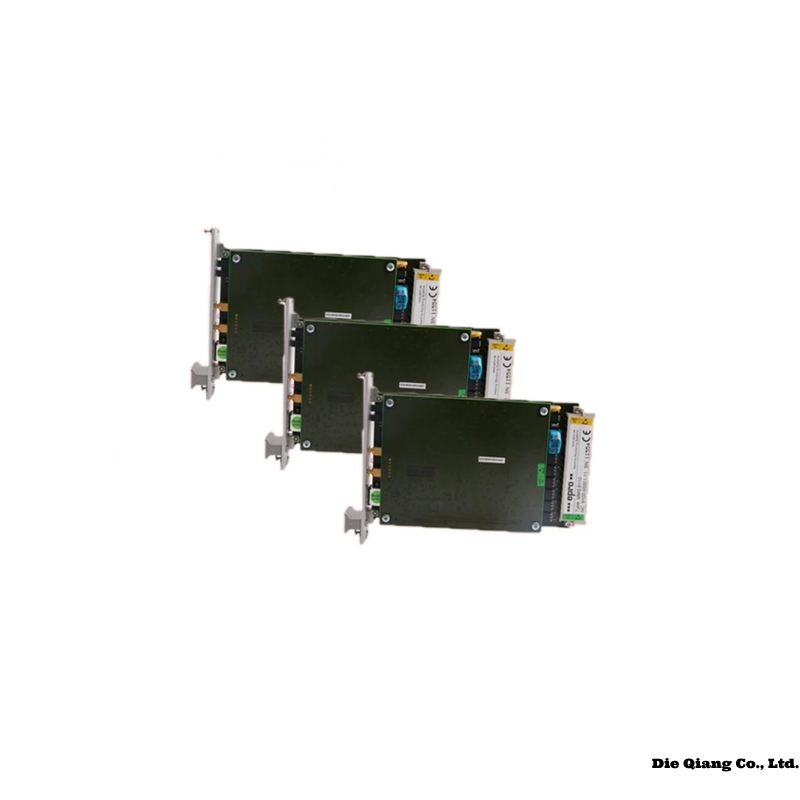

Epro MMS6310 Detailed Product Overview

Product Introduction

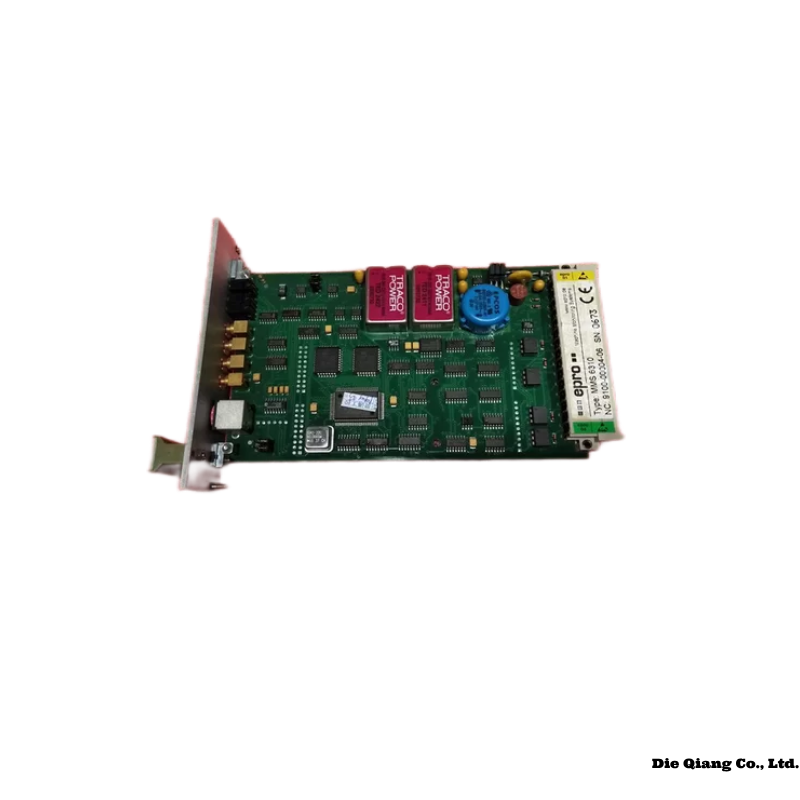

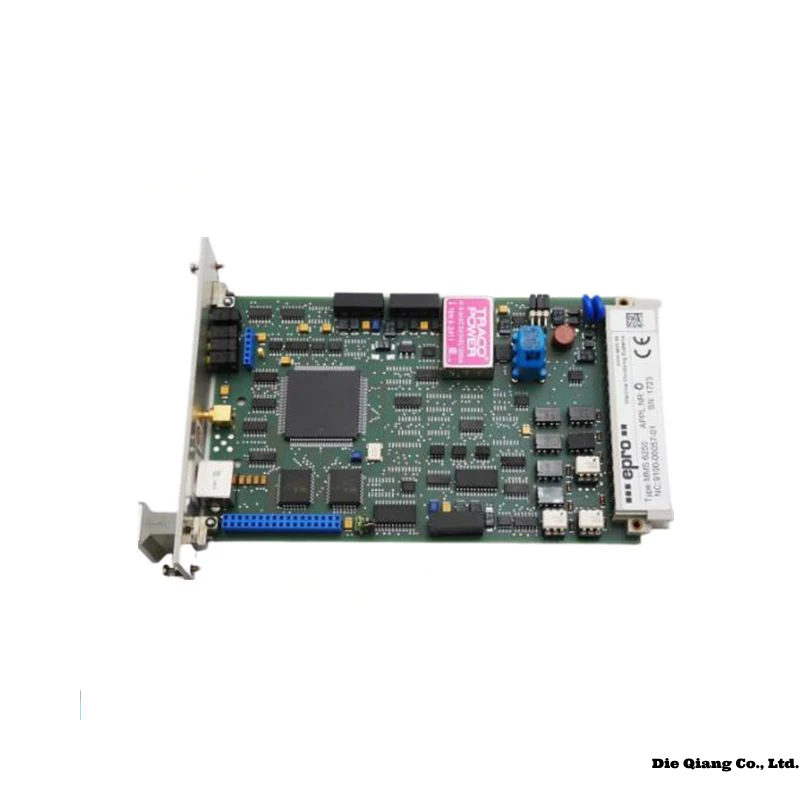

The Epro MMS6310 is a high-performance condition monitoring module designed for advanced industrial applications requiring precise and reliable vibration measurement and analysis. Engineered by Epro, a trusted brand in industrial instrumentation, the MMS6310 integrates seamlessly into monitoring systems to provide real-time data on the operational status of rotating machinery.

Its robust design and compatibility with various sensor types make it an essential component for predictive maintenance, helping prevent unexpected downtime and ensuring the longevity of critical equipment. The MMS6310 excels in detecting imbalances, misalignments, looseness, and bearing faults at an early stage, ensuring plant safety and efficiency.

Product Advantages

-

High Accuracy and Sensitivity

The MMS6310 delivers exceptionally accurate vibration measurements with high sensitivity, ensuring early detection of potential mechanical issues. -

Robust Industrial Design

Designed to withstand harsh industrial environments, the MMS6310 is equipped with rugged housing and high resistance to electromagnetic interference. -

Seamless Integration

Compatible with a wide range of industrial control systems and sensors, allowing easy integration into existing monitoring networks. -

Real-Time Monitoring and Analysis

Supports continuous real-time data acquisition and analysis for effective condition-based maintenance strategies. -

User-Friendly Configuration

Provides flexible configuration options through intuitive software tools, making setup and operation straightforward. -

Enhanced Safety Compliance

Contributes to operational safety by enabling proactive maintenance, reducing the risk of equipment failure.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | Epro MMS6310 |

| Measurement Type | Vibration Monitoring |

| Signal Input | Acceleration, Velocity, Displacement Sensors |

| Measurement Range | 0 to 100 mm/s RMS (Velocity) |

| Frequency Response | 10 Hz to 1,000 Hz |

| Output | 4–20 mA, Relay, Digital Communication |

| Power Supply Voltage | 24 V DC (±10%) |

| Power Consumption | < 5 W |

| Dimensions | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

| Operating Temperature Range | -20°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Housing Material | Industrial-grade Aluminum Alloy |

| Mounting Type | DIN Rail Mounting |

| Protection Class | IP65 |

| Communication Interface | RS485, Modbus RTU |

| Certifications | CE, RoHS, ATEX (Optional) |

Applications

-

Power Generation Plants

Monitoring turbines, generators, and auxiliary equipment to prevent unexpected failures. -

Oil and Gas Industry

Ensuring reliable operation of pumps, compressors, and critical rotating machinery. -

Chemical and Petrochemical Plants

Maintaining safety and efficiency in hazardous environments by monitoring essential equipment. -

Steel and Metal Processing

Protecting heavy-duty machinery such as rolling mills and large motors from wear and damage. -

Pulp and Paper Industry

Enhancing the reliability of paper machines and associated rotating equipment. -

Water Treatment Facilities

Monitoring pumps and motors to support uninterrupted plant operation.

Compatible Models and System Integration

The Epro MMS6310 is designed to work seamlessly with a range of compatible sensors and modules for a fully integrated monitoring solution.

-

PR9268/xx – Vibration Sensors

-

MMS6822 – Communication Gateway

-

PR6423 – Eddy Current Probe

-

MMS3120 – Signal Conditioning Unit

-

MMS3300 – Monitoring System Controller

-

PR9266 – Speed Sensors

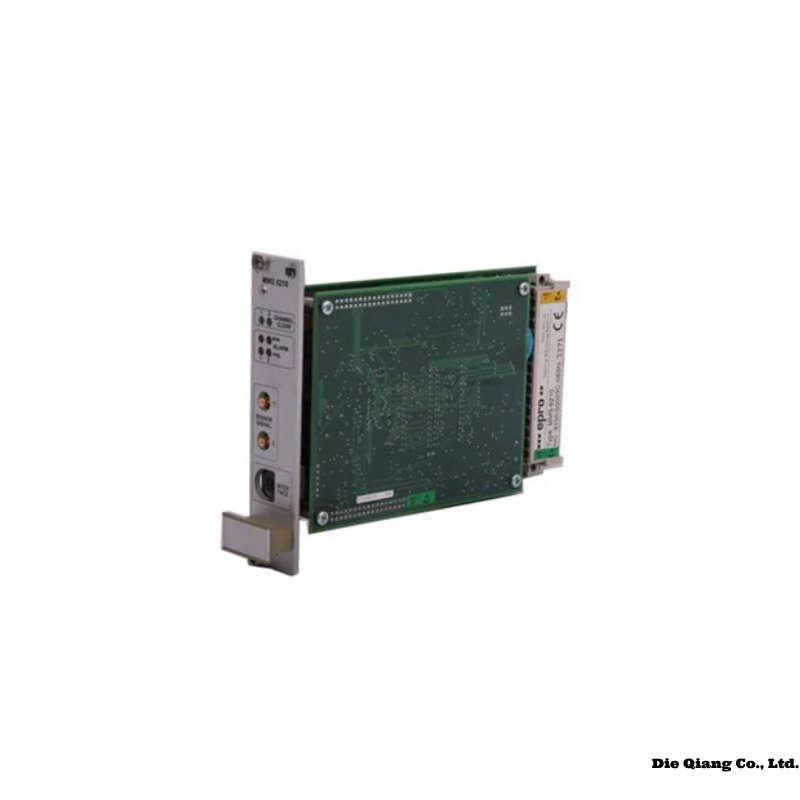

Installation Instructions

-

Preparation

Ensure all installation tools are prepared and verify the power is disconnected before beginning. -

Mounting

Securely mount the MMS6310 on a standard DIN rail inside the control cabinet, ensuring proper ventilation. -

Wiring

Connect the power supply (24 V DC) to the designated terminals. Wire input sensors to the signal input channels and connect the output to the control system or monitoring interface. -

Communication Setup

Configure the RS485 communication lines and ensure proper termination to avoid signal interference. -

Configuration

Use the Epro configuration software to set measurement parameters, alarm thresholds, and communication settings. -

Verification

After installation, perform a functional test to verify proper operation. Ensure all connections are secure and data is accurately transmitted. -

Maintenance

Periodically inspect wiring and connections. Keep the unit clean and free from dust accumulation for optimal performance.

Recommended Related Models (Same Series or Relevant Models)

| Model Number | Description | Measurement Type | Voltage | Dimensions (mm) | Weight (g) |

|---|---|---|---|---|---|

| Epro MMS3120 | Signal Conditioning Unit | Vibration | 24 V DC | 120 x 100 x 50 | 400 |

| Epro MMS6822 | Communication Gateway | Data Communication | 24 V DC | 110 x 90 x 45 | 350 |

| Epro PR6423 | Eddy Current Probe | Displacement | Passive | Ø 8 mm probe, cable: 3 m | 200 |

| Epro PR9268/xx | Vibration Sensor | Vibration | Passive | Ø 30 x 60 | 500 |

| Epro MMS3300 | Monitoring System Controller | Multi-parameter | 24 V DC | 150 x 120 x 60 | 700 |

| Epro PR9266 | Speed Sensor | Speed Monitoring | Passive | Ø 18 x 70 | 400 |

Popular Models from the Same Brand (Epro)

| Model Number | Description | Measurement Type | Voltage | Dimensions (mm) | Weight (g) |

|---|---|---|---|---|---|

| Epro PR9268 | Vibration Sensor | Vibration | Passive | Ø 30 x 60 | 500 |

| Epro PR6423 | Eddy Current Displacement Probe | Displacement | Passive | Ø 8 mm probe, cable: 3 m | 200 |

| Epro MMS3120 | Signal Conditioning Unit | Vibration | 24 V DC | 120 x 100 x 50 | 400 |

| Epro MMS3300 | Monitoring System Controller | Multi-parameter | 24 V DC | 150 x 120 x 60 | 700 |

| Epro MMS6822 | Communication Gateway | Data Communication | 24 V DC | 110 x 90 x 45 | 350 |

| Epro PR6463 | Speed Sensor | Speed Monitoring | Passive | Ø 20 x 80 | 450 |

| Epro PR6424 | Proximity Probe System | Proximity | Passive | Ø 5 mm probe, cable: 5 m | 250 |

| Epro PR9376 | Temperature Sensor | Temperature | Passive | Ø 6 x 50 | 150 |

FAQ (Frequently Asked Questions)

Q1: What types of sensors are compatible with the Epro MMS6310?

A1: The MMS6310 is compatible with a variety of vibration sensors, including the PR9268 series, eddy current probes like the PR6423, and speed sensors such as the PR9266.

Q2: Can the MMS6310 operate in hazardous environments?

A2: Yes, the MMS6310 is designed for industrial environments and can be optionally certified for ATEX compliance, making it suitable for hazardous areas.

Q3: How is the MMS6310 configured?

A3: Configuration is performed using dedicated Epro configuration software, which allows users to set measurement ranges, alarm thresholds, and communication protocols.

Q4: Does the MMS6310 support remote monitoring?

A4: Yes, the MMS6310 supports remote monitoring via RS485 and Modbus RTU communication interfaces, allowing integration with centralized control systems.

Q5: What maintenance is required for the MMS6310?

A5: Routine maintenance includes checking all wiring connections, cleaning the unit to prevent dust buildup, and periodically verifying measurement accuracy.

Q6: What is the typical service life of the MMS6310?

A6: Under normal operating conditions, the MMS6310 has a typical service life exceeding 10 years, provided that regular maintenance is performed.

Epro MMS6310 Dual Channel Key- pulse Monitor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||