| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

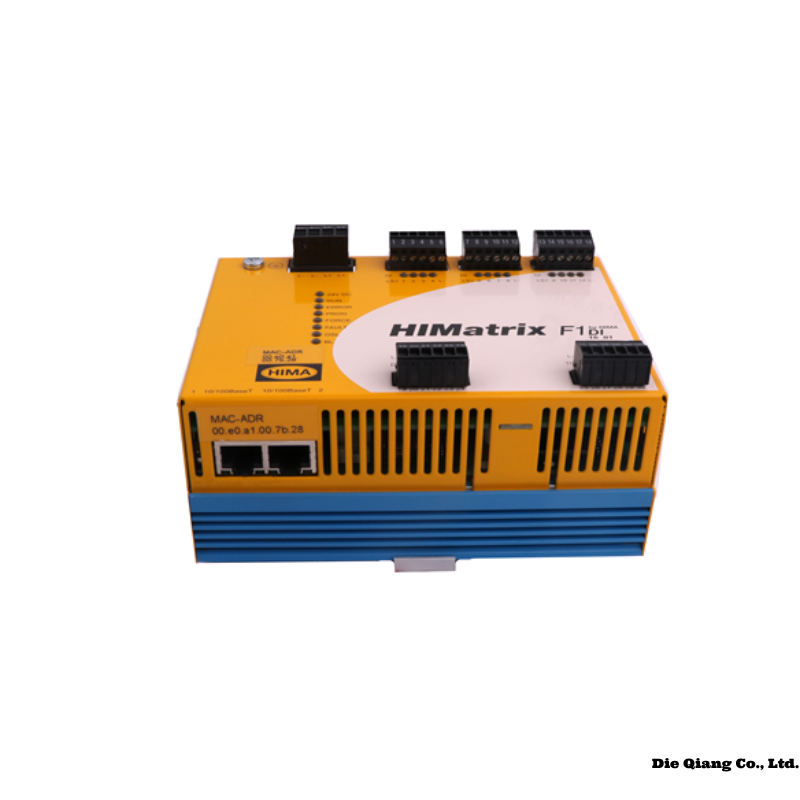

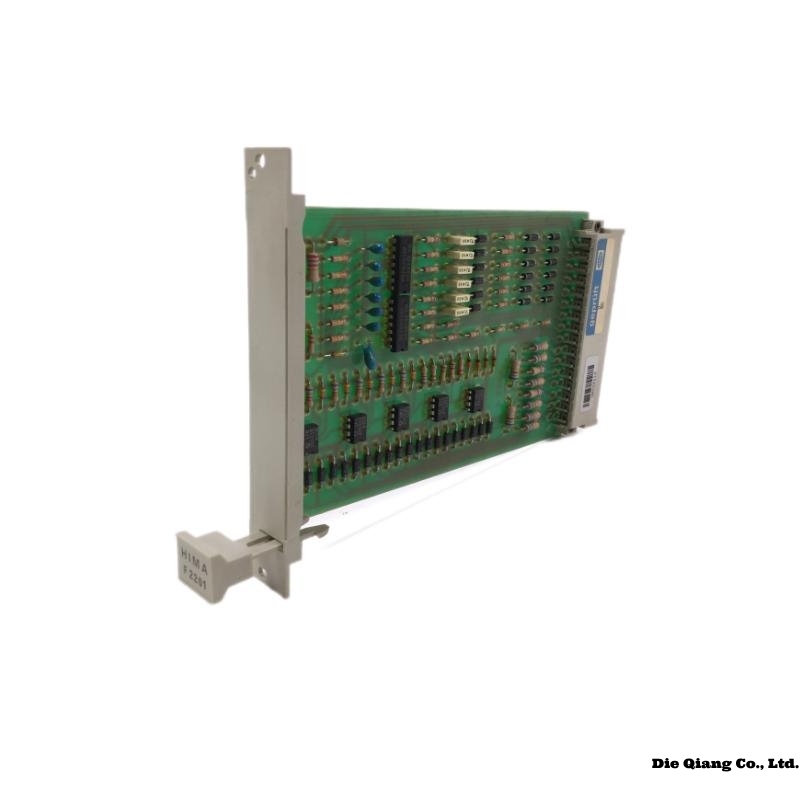

The HIMA F1 DI 16 01 is a high-performance digital input module designed for industrial safety systems. It is part of HIMA’s F1 series, which is widely used in critical safety applications such as process automation, machinery protection, and emergency shutdown systems. This module ensures reliable signal acquisition and processing, making it ideal for harsh industrial environments.

The F1 DI 16 01 provides 16 digital input channels, allowing for the monitoring of multiple safety-critical signals. It features robust construction, high noise immunity, and compliance with international safety standards, ensuring long-term reliability and performance.

Product Advantages

- High Reliability – Designed for mission-critical applications with a focus on fail-safe operation.

- Wide Compatibility – Integrates seamlessly with HIMA’s safety systems and other industrial control systems.

- Robust Design – Built to withstand harsh industrial conditions, including extreme temperatures and electrical noise.

- Easy Diagnostics – Features advanced diagnostic capabilities for quick troubleshooting.

- Compliance with Standards – Meets IEC 61508, SIL 3, and other industry safety standards.

- Modular Design – Allows for easy expansion and integration within existing systems.

Technical Parameters

| Parameter | Specification |

|---|---|

| Number of Channels | 16 digital inputs |

| Input Voltage | 24V DC (nominal) |

| Operating Voltage | 18V – 30V DC |

| Power Consumption | ≤ 5W |

| Dimensions (WxHxD) | 152 x 114 x 66 mm |

| Weight | 0.7 kg |

| Operating Temp. | -20°C to +60°C |

| Protection Class | IP20 |

| Certifications | SIL 3, IEC 61508 |

Applications

The HIMA F1 DI 16 01 is widely used in:

- Process Industries (Oil & Gas, Chemical, Power Plants) – For emergency shutdown systems (ESD).

- Manufacturing Automation – Safety monitoring in robotic systems and assembly lines.

- Railway Signaling – Ensuring fail-safe signal processing.

- Machinery Safety – Interlocking and emergency stop functions.

Compatible & Recommended Models

The F1 DI 16 01 can be used with:

- HIMA F1 CPU (Safety Controller)

- HIMA F1 AI 8 01 (Analog Input Module)

- HIMA F1 DO 16 01 (Digital Output Module)

- HIMA F1 COM 01 (Communication Module)

6 Recommended Related Models (Same Series)

| Model | Channels | Voltage | Dimensions (mm) | Weight | Key Feature |

|---|---|---|---|---|---|

| HIMA F1 DI 8 01 | 8 digital | 24V DC | 60 x 120 x 115 | 0.4 kg | Compact design |

| HIMA F1 DO 16 01 | 16 digital | 24V DC | 60 x 120 x 115 | 0.5 kg | High-current outputs |

| HIMA F1 AI 8 01 | 8 analog | 24V DC | 60 x 120 x 115 | 0.45 kg | Precision measurement |

| HIMA F1 COM 01 | N/A | 24V DC | 60 x 120 x 115 | 0.5 kg | Ethernet communication |

| HIMA F1 CPU 01 | N/A | 24V DC | 120 x 120 x 115 | 0.8 kg | Central processing unit |

| HIMA F1 DI 32 01 | 32 digital | 24V DC | 120 x 120 x 115 | 0.9 kg | High-density inputs |

8 Popular HIMA Models (Other Series)

| Model | Type | Voltage | Dimensions (mm) | Weight | Key Feature |

|---|---|---|---|---|---|

| HIMA H41q CPU | Safety PLC | 24V DC | 200 x 150 x 80 | 1.2 kg | SIL 3 certified |

| HIMA H51q DI 32 | Digital Input | 24V DC | 120 x 120 x 115 | 0.9 kg | High-speed inputs |

| HIMA H61q AI 16 | Analog Input | 24V DC | 120 x 120 x 115 | 0.8 kg | 16-channel precision |

| HIMA H71q DO 8 | Digital Output | 24V DC | 60 x 120 x 115 | 0.5 kg | Relay outputs |

| HIMA H81q COM | Communication | 24V DC | 60 x 120 x 115 | 0.5 kg | PROFIBUS support |

| HIMA H91q PS | Power Supply | 110-240V AC | 200 x 150 x 80 | 1.5 kg | Redundant power |

| HIMA H10q CPU | Safety Controller | 24V DC | 200 x 150 x 80 | 1.3 kg | High-performance |

| HIMA H11q DI 16 | Digital Input | 24V DC | 60 x 120 x 115 | 0.5 kg | SIL 2 certified |

Installation Instructions

- Mounting – Install the module on a DIN rail in a control cabinet.

- Wiring – Connect the input signals to the terminal blocks as per the wiring diagram.

- Power Supply – Ensure a stable 24V DC supply is connected to the designated terminals.

- Grounding – Properly ground the module to avoid electrical noise interference.

- Configuration – Use HIMA’s configuration software to set up the module parameters.

- Testing – Verify all inputs and diagnostics before putting the system into operation.

FAQ (Frequently Asked Questions)

Q1: What is the maximum input voltage for the F1 DI 16 01?

A1: The module supports up to 30V DC continuously.

Q2: Is the module SIL 3 certified?

A2: Yes, it complies with SIL 3 as per IEC 61508.

Q3: Can it be used in explosive environments?

A3: No, it is rated for IP20 and should be installed in a protected enclosure.

Q4: What is the response time of the inputs?

A4: Typically less than 10 ms per channel.

Q5: Can I mix different input signals (e.g., 12V & 24V)?

A5: No, all inputs must operate at the same nominal voltage (24V DC).

Q6: Does it support hot swapping?

A6: No, the module must be powered down before installation or removal.

HIMA F1 DI 16 01 Remote I/O Module

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||