| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

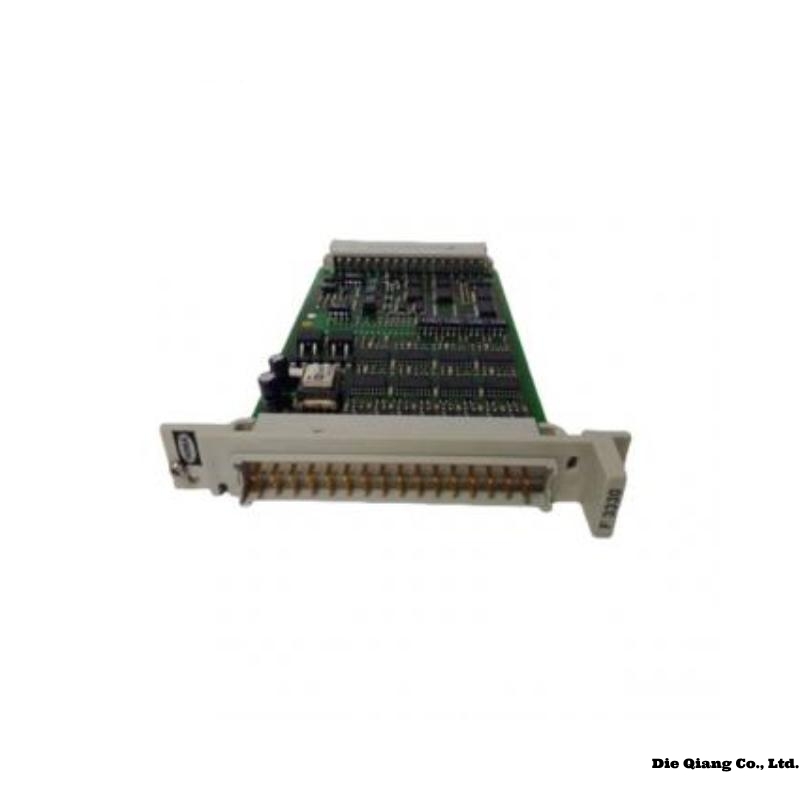

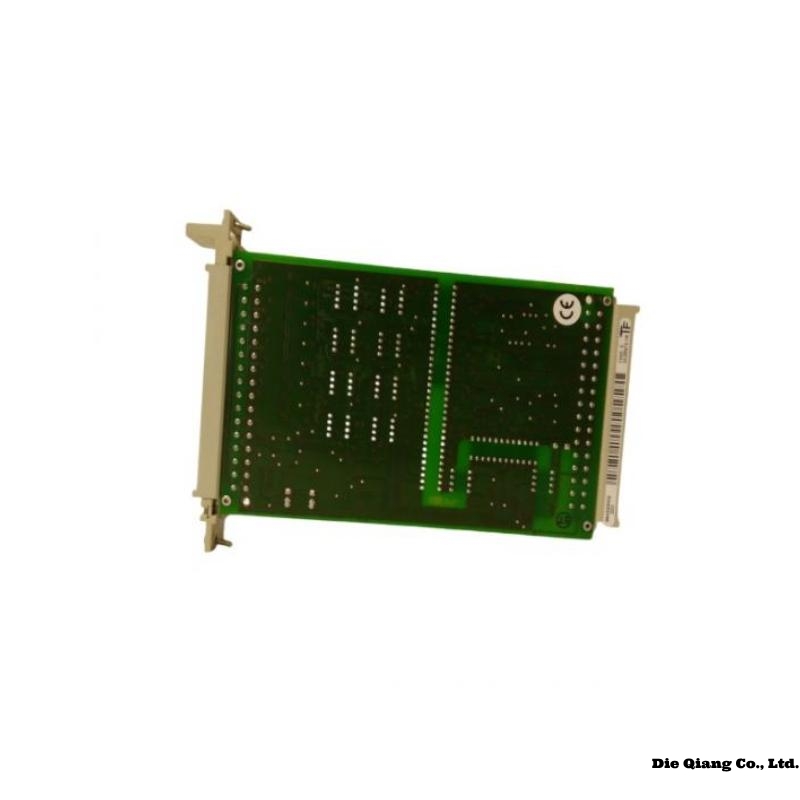

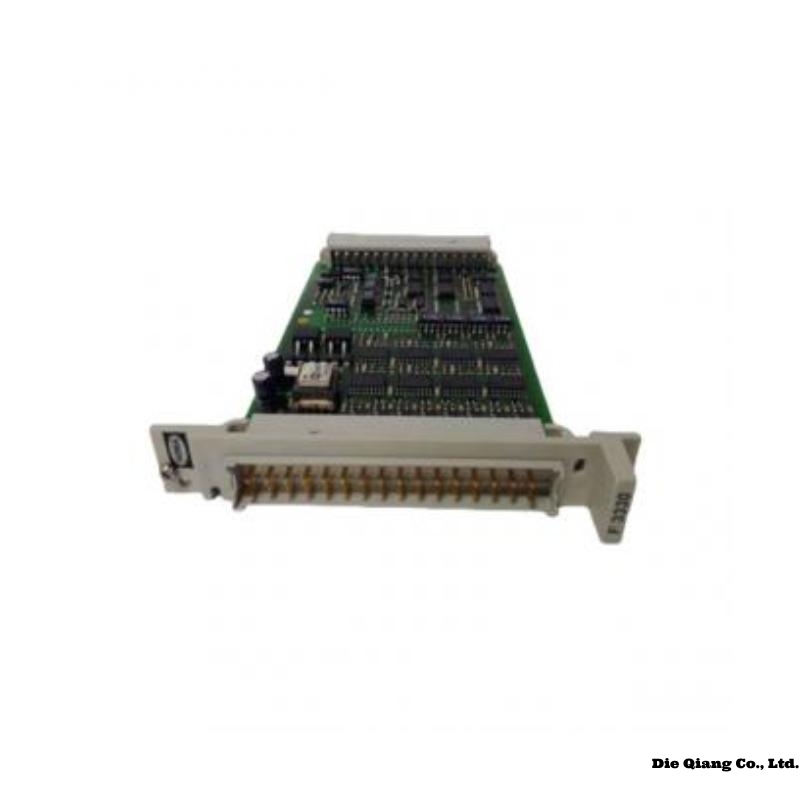

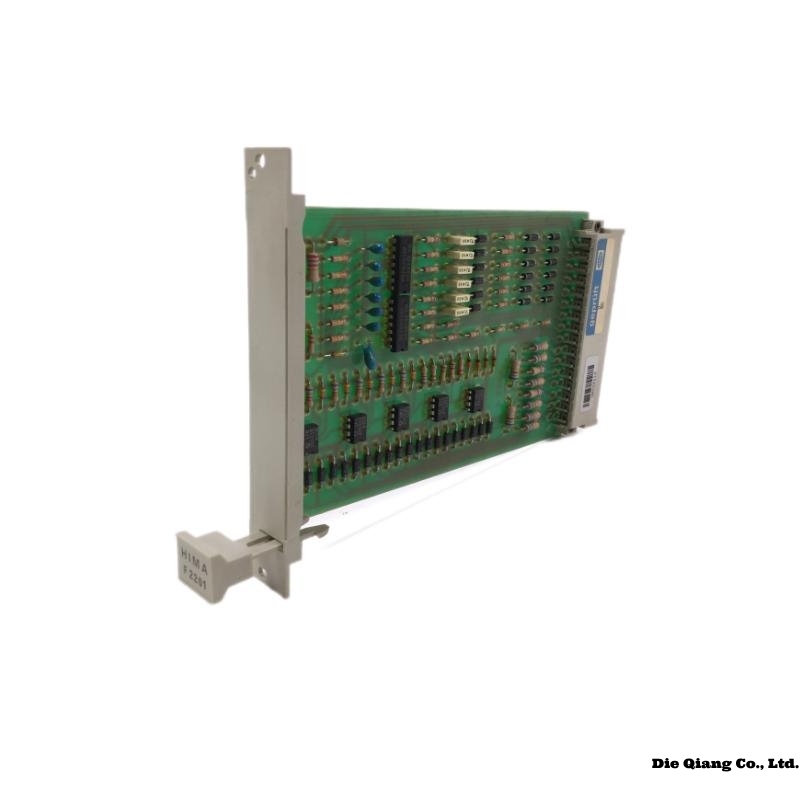

The HIMA F2102 is a high-performance safety system controller, designed for use in critical industrial applications where safety and reliability are of utmost importance. This product is part of HIMA’s extensive line of safety controllers, which are recognized for their robustness and ability to meet rigorous safety standards. The F2102 integrates seamlessly into various automated systems, ensuring consistent, secure operations in sectors such as oil and gas, chemicals, power plants, and other high-risk environments.

This product is specifically engineered for safety applications, ensuring that any faults in the system do not lead to hazardous conditions. It supports multiple communication protocols and interfaces, offering great flexibility in system integration.

Advantages

-

High Reliability: The HIMA F2102 is built with robust redundancy and fault-tolerant mechanisms, ensuring that the system continues to operate safely even in the event of failures.

-

Flexible Integration: With its support for various industrial communication protocols, the F2102 is easy to integrate into existing systems without the need for extensive reconfiguration.

-

Compact Design: The F2102’s compact form factor allows it to be used in space-constrained environments, making it ideal for applications where space is limited.

-

Comprehensive Safety Standards Compliance: The F2102 meets international safety standards, including IEC 61508 and IEC 61511, which makes it suitable for use in safety-critical industries.

-

Scalability: The F2102 can be scaled to meet the needs of small to large safety systems, providing flexibility in system design.

-

Durable: Designed for use in harsh industrial environments, the F2102 is highly durable and resistant to environmental factors like temperature fluctuations, vibrations, and dust.

Technical Specifications

| Parameter | Specification |

|---|---|

| Dimensions | 255 x 114 mm |

| Weight | 2 kg |

| Voltage | 24 V DC |

| Power Consumption | 12 W |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Communication | Modbus, Profibus, Ethernet/IP, HART |

| Inputs | 8 digital inputs, 4 analog inputs |

| Outputs | 8 digital outputs, 4 analog outputs |

| Certification | SIL 3 (Safety Integrity Level) |

| MTBF | 50,000 hours |

Applications

The HIMA F2102 is used across various industries where safety and automation are crucial. Typical applications include:

-

Oil and Gas: In offshore and onshore operations, the F2102 ensures safe monitoring and control of critical processes such as drilling and refining.

-

Chemical Processing: It is used to monitor and control hazardous chemical processes, ensuring they remain within safe operational limits.

-

Power Plants: The F2102 plays a key role in managing safety systems for boilers, turbines, and other critical infrastructure in power generation.

-

Manufacturing: In manufacturing facilities, the F2102 is used to safeguard automated production lines.

-

Mining: The F2102 ensures the safety of complex mining equipment and processes, reducing risk in high-risk mining operations.

Compatible Models

The HIMA F2102 is part of a comprehensive safety system product range. Here are some compatible models that work seamlessly with the F2102:

| Model | Description |

|---|---|

| HIMA F3201 | Advanced safety controller with enhanced I/O capabilities. |

| HIMA F3001 | Compact safety controller ideal for smaller systems. |

| HIMA F3401 | High-performance controller with expanded network connectivity. |

| HIMA F3402 | Version with additional redundancy and fault tolerance features. |

| HIMA F2100 | Entry-level safety system for basic safety applications. |

| HIMA F2200 | Modular safety controller offering flexibility in system design. |

Installation Instructions

-

Unbox and Inspect: Carefully unbox the HIMA F2102 and inspect for any physical damage.

-

Mounting: Install the controller in a standard 19-inch rack or on a DIN rail using the provided mounting kit.

-

Wiring: Connect the power supply and input/output lines as per the wiring diagram provided in the manual.

-

Communication Setup: Configure the communication interfaces (Modbus, Profibus, Ethernet/IP, etc.) according to the system requirements.

-

Testing: After installation, conduct a series of tests to ensure that all connections are functional and that the system operates as expected.

-

Calibration: Calibrate any analog inputs or outputs based on the specific requirements of the application.

-

System Integration: Finally, integrate the F2102 into the larger automation or safety system, ensuring that all interlocks, alarms, and shutdown processes are in place.

FAQ (Frequently Asked Questions)

Q1: What is the warranty period for the HIMA F2102?

A1: The HIMA F2102 comes with a 2-year warranty period from the date of purchase, covering any manufacturing defects.

Q2: Can the F2102 be used in hazardous environments?

A2: Yes, the F2102 is designed to be used in hazardous environments, and it complies with safety standards for industrial applications in such areas.

Q3: Is it compatible with third-party devices?

A3: Yes, the F2102 supports several industry-standard communication protocols such as Modbus, Profibus, and Ethernet/IP, allowing it to integrate with third-party devices.

Q4: How do I configure the HIMA F2102 for my specific application?

A4: Configuration of the F2102 can be done through its user-friendly configuration software, where you can set parameters, communication settings, and safety protocols based on your system requirements.

Q5: What safety certifications does the F2102 have?

A5: The F2102 is certified to meet SIL 3 (Safety Integrity Level), ensuring its suitability for critical safety applications in industries such as oil and gas, chemical processing, and power generation.

Q6: Can I expand the system with additional I/O modules?

A6: Yes, the F2102 system can be expanded by connecting additional I/O modules depending on the needs of your specific application.

Popular Models from HIMA

In addition to the HIMA F2102, here are some other popular models from the same brand:

| Model | Description | Specifications |

|---|---|---|

| HIMA F3200 | High-performance safety controller for large systems. | Voltage: 24 V DC, Dimensions: 200x150x120 mm, SIL 3 |

| HIMA F3300 | Modular safety system with scalable configuration. | Voltage: 24 V DC, Dimensions: 180x140x130 mm, SIL 3 |

| HIMA F2000 | Compact and reliable safety controller. | Voltage: 24 V DC, Dimensions: 150x100x100 mm, SIL 2 |

| HIMA F3400 | Advanced system for high-complexity operations. | Voltage: 24 V DC, Dimensions: 210x160x130 mm, SIL 3 |

| HIMA F3500 | Suitable for applications requiring extensive inputs. | Voltage: 24 V DC, Dimensions: 220x170x140 mm, SIL 3 |

| HIMA F3600 | High availability controller for critical systems. | Voltage: 24 V DC, Dimensions: 230x180x150 mm, SIL 3 |

| HIMA F5000 | Modular system with extensive diagnostic features. | Voltage: 24 V DC, Dimensions: 240x190x160 mm, SIL 4 |

| HIMA F2103 | Extended I/O safety controller for medium-sized systems. | Voltage: 24 V DC, Dimensions: 160x110x120 mm, SIL 2 |

HIMA F2102 Smart Safety Module

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||