| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

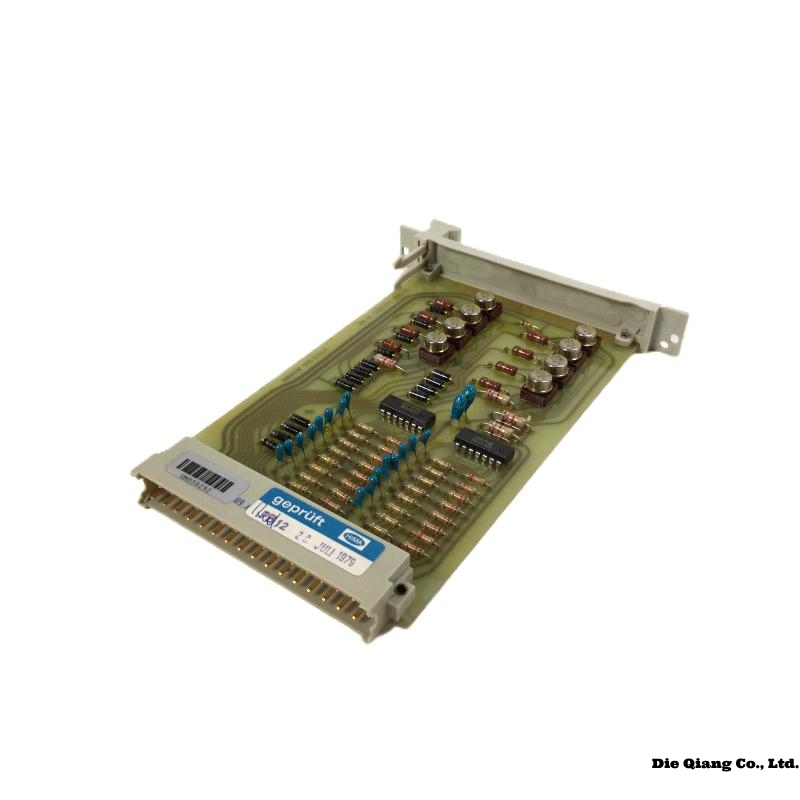

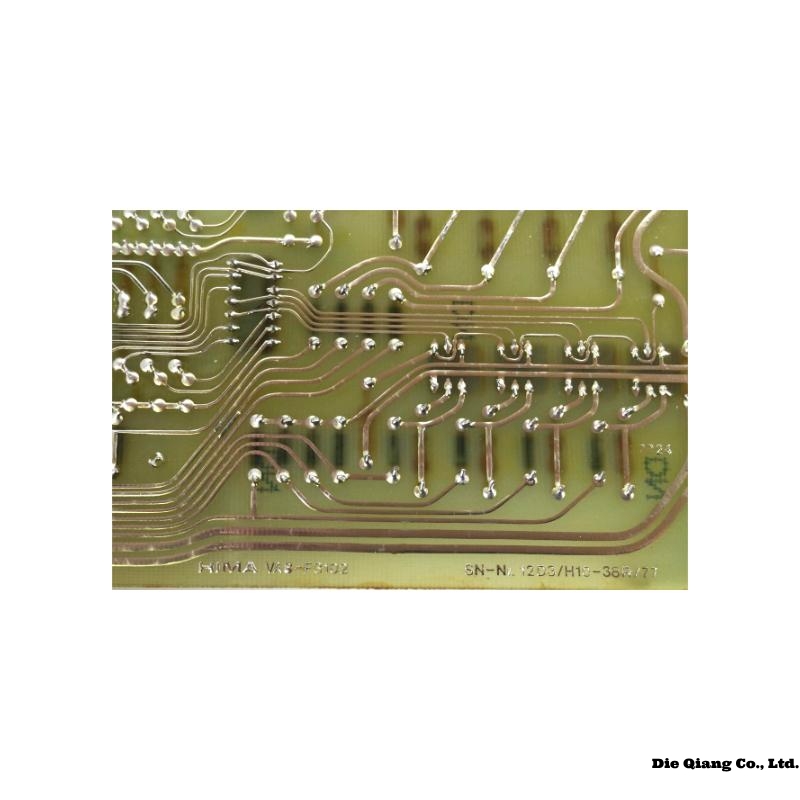

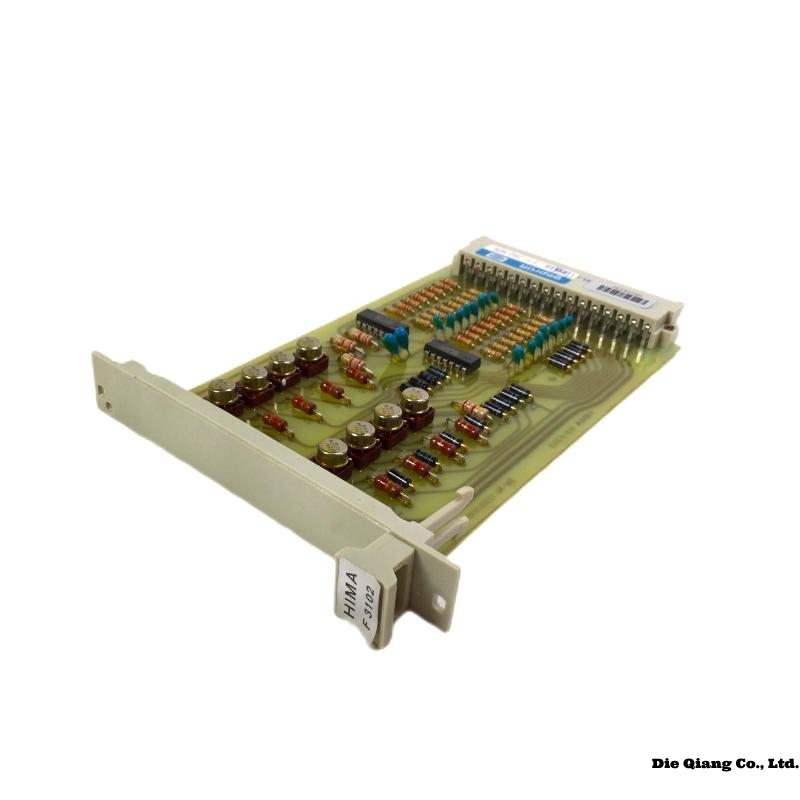

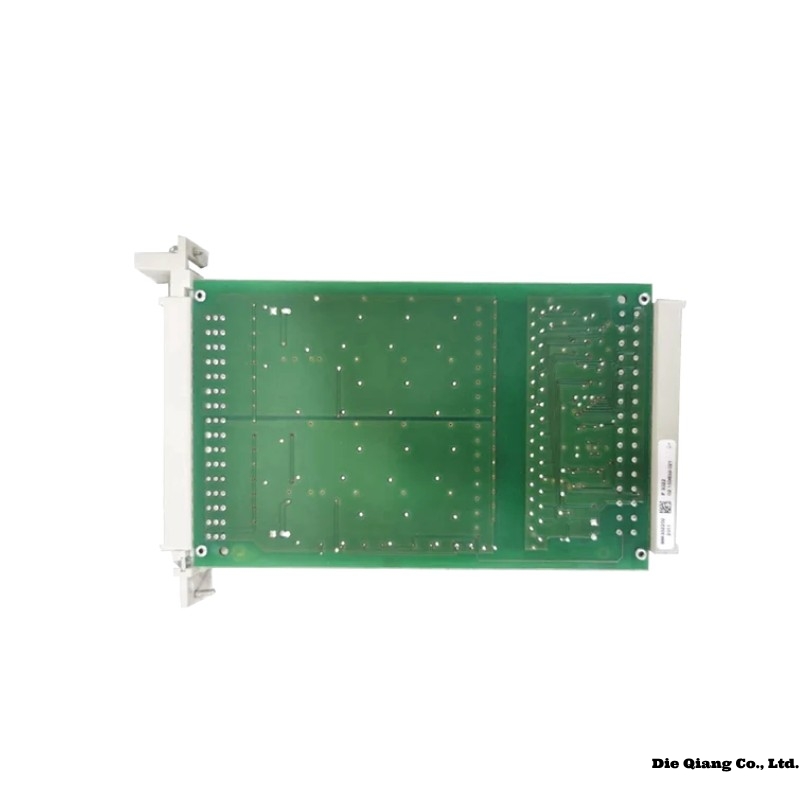

📘 Product Introduction: HIMA F3102

The HIMA F3102 is a high-performance, safety-oriented digital input module developed for use in the HIMA HIMax and HIQuad safety systems. Designed to meet the rigorous requirements of functional safety and process automation, the F3102 module provides reliable input signal processing for critical industrial applications. It supports the acquisition of binary signals from field devices such as limit switches, pressure sensors, or emergency stop buttons.

Engineered to meet SIL 3 in accordance with IEC 61508, the F3102 is ideal for safety-related applications in the oil and gas, power generation, chemical, and pharmaceutical industries. With a modular design, superior diagnostic features, and robust isolation mechanisms, it ensures both safety integrity and high availability in safety instrumented systems (SIS).

✅ Product Advantages

-

SIL 3 Certified: Complies with IEC 61508 up to Safety Integrity Level 3, ensuring reliable operation in safety-critical environments.

-

Comprehensive Diagnostics: Features advanced diagnostics to detect wire breaks, short circuits, and internal failures, minimizing downtime.

-

Hot Swappable: Allows for module replacement during operation without shutting down the system, increasing availability.

-

Electrically Isolated Channels: Each channel is galvanically isolated from the system and field circuits, reducing interference.

-

Compact and Modular: Saves space in control cabinets and allows for flexible system expansion.

-

High-Speed Response: Enables real-time input processing for applications requiring rapid detection and reaction.

📊 Technical Specifications of HIMA F3102

| Parameter | Details |

|---|---|

| Module Type | Digital Input Module (Safety-Critical) |

| Number of Channels | 16 channels |

| Input Type | 24 V DC binary input (non-isolated from field wiring) |

| Rated Input Voltage | 24 V DC (nominal) |

| Voltage Range | 18–30 V DC |

| Input Current | Approx. 6 mA at 24 V DC |

| Input Delay Time | <10 ms (filter adjustable) |

| Electrical Isolation | Channel-to-system: Galvanic isolation |

| Diagnostic Functions | Line break, short circuit, internal fault detection |

| Safety Level | SIL 3 (IEC 61508), Category 4 (EN 954-1), PL e (EN ISO 13849) |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95%, non-condensing |

| Mounting | DIN Rail mounting |

| Dimensions | 200 x 100 mm |

| Weight | 0.5 kg |

| Power Supply | 24 V DC (supplied via backplane) |

| Protection Class | IP20 |

| Compatibility | HIMax, HIQuad, Planar4 systems |

🛠 Applications

-

Emergency Shutdown Systems (ESD)

-

Fire and Gas Detection Systems (F&G)

-

Turbine Control Systems

-

Pipeline Monitoring

-

Boiler Safety Control

-

Automated Safety Interlocks in Chemical Plants

-

Offshore Oil & Gas Platforms

-

Nuclear and Conventional Power Stations

🔧 Compatible and Supporting Models

The HIMA F3102 module is designed to work seamlessly with the following systems and modules:

-

HIMax Safety System Platform

-

HIQuad Safety System

-

HIMA F30 Series I/O Modules

-

HIMA CPU F8650X / F8627X / F8607

-

HIMA Communication Modules F7126 / F7130

-

HIMA Terminal Blocks and Backplanes (e.g., X200 series)

🔩 Installation Instructions

-

Ensure Power is Off

Before installing the F3102, disconnect all power sources to the backplane and system to avoid electrical hazards. -

Mount the Module

Secure the module onto the DIN rail in the correct slot of the HIMax or HIQuad backplane. Ensure it clicks firmly into place. -

Connect Field Wiring

Attach signal wiring from field devices to the module’s terminal block. Ensure proper labeling and polarity. -

Check Compatibility

Verify that the firmware and hardware version of the system controller are compatible with the F3102 module. -

Power On and Diagnose

Re-energize the system and allow it to initialize. Use system diagnostics to verify the proper functioning of the module. -

Configure via Engineering Tool

Use HIMA’s ELOP II or SILworX software to configure and validate input channels according to the safety application. -

Perform Loop Test

Test each input channel using live field signals to verify correct operation and ensure safety readiness.

🔁 Related or Similar Models (F30 Series)

| Model | Description | Channels | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|---|

| F3101 | Digital Input Module, Basic | 8 | 24 V DC | 40 x 115 x 130 | 420 g |

| F3113 | Digital Input Module, High Diagnosis | 16 | 24 V DC | 40 x 115 x 130 | 460 g |

| F3221 | Digital Output Module, Relay | 8 | 24 V DC | 40 x 115 x 130 | 470 g |

| F3226 | Digital Output Module, Transistor | 16 | 24 V DC | 40 x 115 x 130 | 460 g |

| F3330 | Analog Input Module, 4–20 mA | 8 | 24 V DC | 40 x 115 x 130 | 490 g |

| F3237 | Digital Output Module, Redundant | 16 | 24 V DC | 40 x 115 x 130 | 480 g |

⭐ 8 Popular HIMA Modules (Top Recommended)

| Model | Type | Description | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|---|

| F8650X | CPU Module | High-performance safety controller | 24 V DC | 50 x 160 x 145 | 650 g |

| F7553 | Power Supply Module | For HIMax power redundancy | 24 V DC | 40 x 115 x 130 | 480 g |

| F7126 | Communication Module | PROFIBUS Interface for HIMax | 24 V DC | 40 x 115 x 130 | 460 g |

| F3226 | Digital Output Module | Transistor output module | 24 V DC | 40 x 115 x 130 | 460 g |

| F3330 | Analog Input Module | Current signal input (4–20 mA) | 24 V DC | 40 x 115 x 130 | 490 g |

| F3236 | Relay Output Module | Potential-free contacts for process control | 24 V DC | 40 x 115 x 130 | 475 g |

| F3001 | Base Module | Carrier module for I/O modules | — | 100 x 130 x 120 | 510 g |

| F7130 | Communication Gateway | Ethernet-based system communication | 24 V DC | 40 x 115 x 130 | 470 g |

❓ Frequently Asked Questions (FAQ)

Q1: What is the main purpose of the HIMA F3102 module?

A1: The HIMA F3102 is used to process digital input signals from field devices in safety-critical applications, ensuring reliable monitoring of binary events in industrial environments.

Q2: Can the F3102 module be replaced during system operation?

A2: Yes, the F3102 supports hot-swapping, meaning it can be safely replaced without shutting down the system, provided the appropriate safety procedures are followed.

Q3: Which software is used to configure the F3102?

A3: Configuration is typically performed using HIMA’s SILworX or ELOP II engineering software, depending on the platform and application.

Q4: What kind of diagnostics are available on the F3102?

A4: The module supports diagnostics such as wire break detection, short circuit monitoring, and internal self-testing to ensure operational integrity.

Q5: Is the F3102 compatible with legacy HIMA systems?

A5: The F3102 is primarily intended for use with the HIMax and HIQuad systems. Compatibility with older platforms like Planar4 must be verified with system documentation or HIMA support.

Q6: What safety standards does the F3102 comply with?

A6: The module complies with IEC 61508 (SIL 3), EN ISO 13849 (PL e), and EN 954-1 (Category 4) for high-integrity safety functions.

HIMA F3102 Buffer Amplifier Module

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||