| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

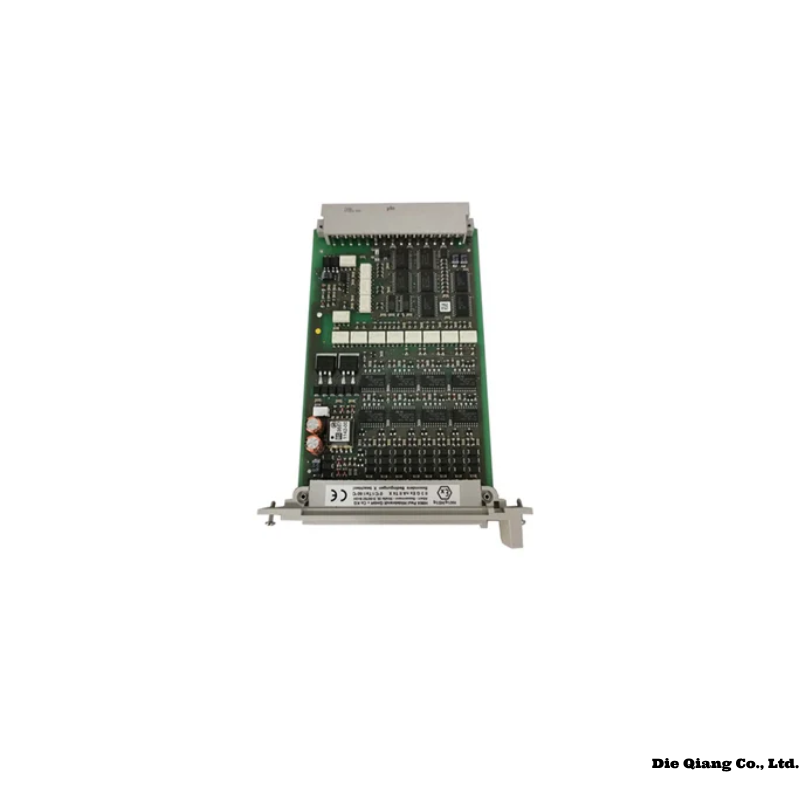

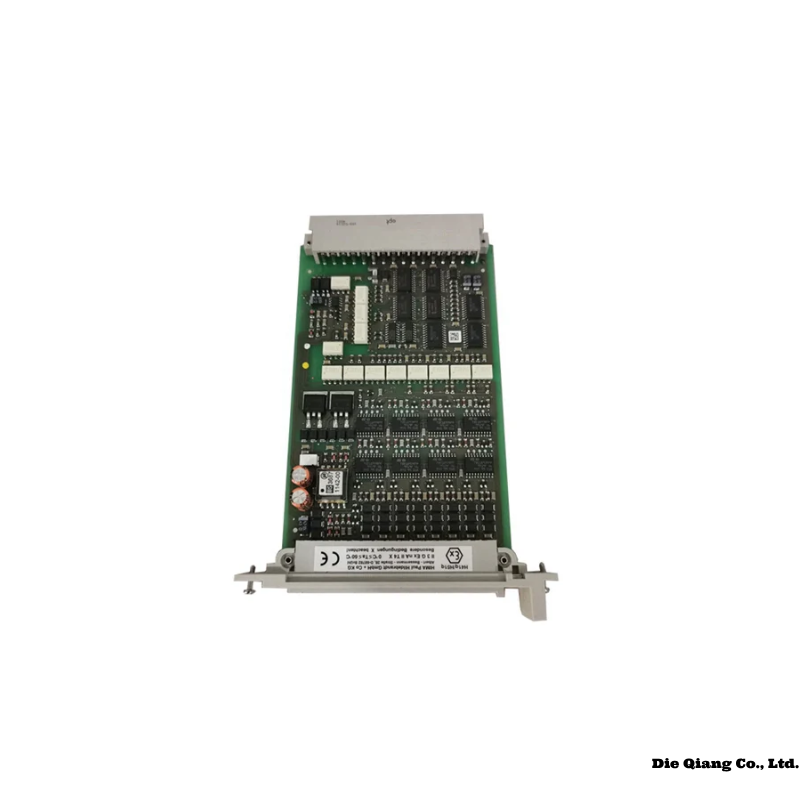

HIMA F3331 Product Introduction

The HIMA F3331 is a safety-related control system designed for applications that require high availability and reliability. It is part of HIMA’s advanced series of safety controllers, typically used in industrial environments for process automation, safety monitoring, and critical control applications. The F3331 ensures safe operation of machinery, process units, and plants by applying high-standard safety protocols, which align with international safety regulations and standards such as IEC61508 and SIL (Safety Integrity Level).

Product Advantages

- High Safety Standards: The F3331 adheres to SIL 3 safety levels, making it ideal for critical and high-risk environments.

- Modular and Scalable Design: The system can be easily adapted to varying process requirements by adding or removing modules as needed.

- Reliability and Fault-Tolerance: It offers built-in redundancy, ensuring a robust and continuous operation, even in the event of faults.

- Compact and Flexible: The product’s small footprint and modular configuration provide great flexibility and ease of integration into different control systems.

- Fast Response Times: The F3331 features quick processing speeds that are essential for fast safety responses.

- Easy Integration: Seamless integration with other industrial control equipment ensures operational efficiency.

Technical Specifications

| Parameter | Value |

|---|---|

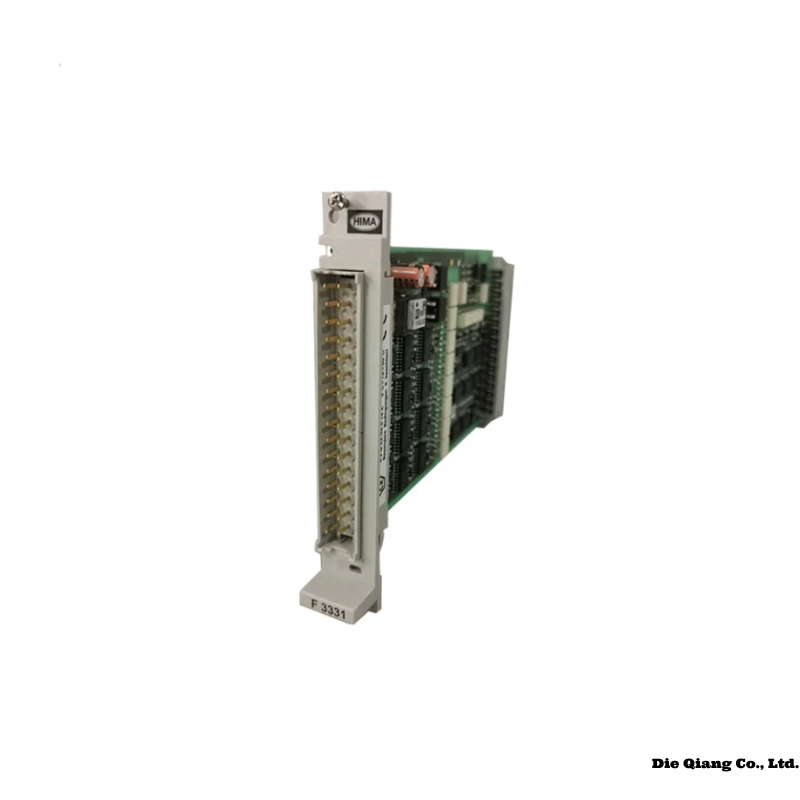

| Product Name | HIMA F3331 |

| Safety Integrity Level | SIL 3 |

| Power Supply | 24 VDC ± 20% |

| Dimensions | 120 x 160 x 40 mm |

| Weight | 0.109kg |

| Input Voltage | 24 VDC |

| Output Type | Relay Outputs, Digital I/O |

| Mounting Type | DIN Rail |

| Communication Ports | 2 x Ethernet, 1 x RS485 |

| Temperature Range | -20°C to +60°C |

| Humidity | 5% to 95% non-condensing |

Product Applications

The HIMA F3331 is used in a wide variety of safety-critical applications including:

- Chemical plants: Ensuring safe operation of hazardous processes and systems.

- Oil and Gas: Protecting drilling and production platforms.

- Power Generation: Monitoring and controlling safety systems in power plants.

- Manufacturing and Automation: Managing safety protocols in automated production lines.

Compatible Models for Use with HIMA F3331

| Model | Description |

|---|---|

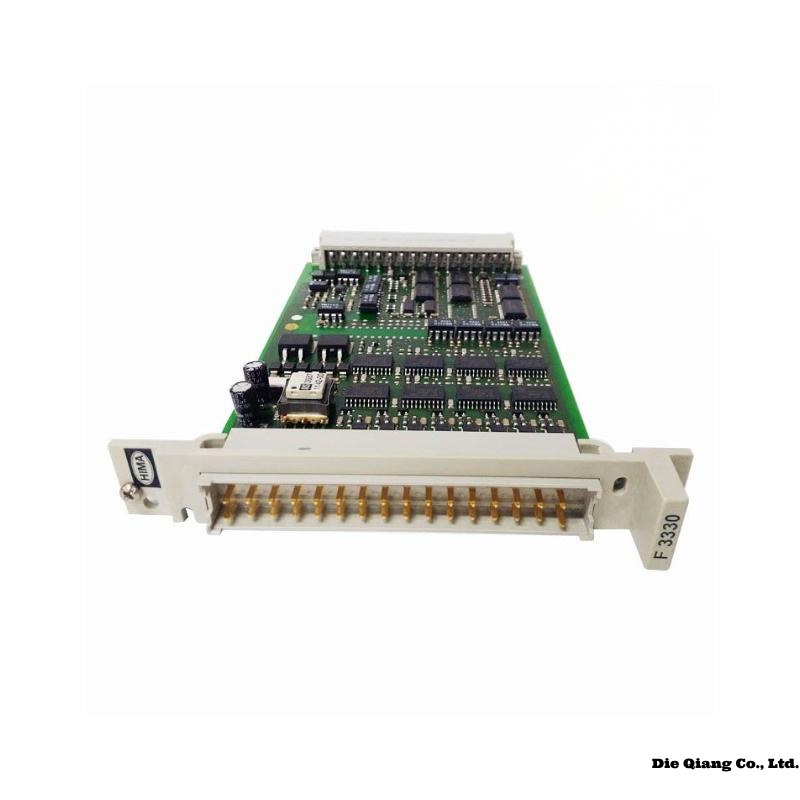

| F3230 | Safety controller for general industrial use |

| F2131 | High-performance controller for process safety |

| F3400 | Advanced fault-tolerant safety system |

| F3330 | Small-scale safety controller |

| F5000 | Modular and scalable safety control system |

| F6000 | High-end redundant control system |

Installation Instructions

- Pre-installation checks: Ensure the system is powered off and all components are properly grounded before beginning installation.

- Mounting: The F3331 should be mounted on a standard DIN rail. Ensure that the mounting location is free from excessive vibrations and electromagnetic interference.

- Wiring: Connect the power supply to the designated input terminals. Ensure that all communication and I/O connections are made according to the product’s wiring diagram.

- Configuration: Using the HIMA configuration software, set up the F3331 for your specific application. This may include configuring inputs, outputs, and safety parameters.

- Testing: Conduct thorough testing of the system after installation to ensure that all safety functions are operational.

- Documentation: Keep detailed records of the installation and configuration for future reference.

Frequently Asked Questions (FAQ)

Q1: What is the maximum number of modules that can be connected to the HIMA F3331?

A1: The maximum number of modules depends on the specific configuration, but the system can support up to 16 modules in total.

Q2: Can the F3331 be used in hazardous areas?

A2: Yes, the F3331 is certified for use in hazardous environments, provided proper safety measures are in place.

Q3: Is the HIMA F3331 compatible with third-party devices?

A3: Yes, it supports standard communication protocols like Modbus and Ethernet, allowing integration with third-party devices.

Q4: What is the expected lifespan of the F3331?

A4: With proper maintenance, the F3331 can operate for up to 10 years.

Q5: Can I remotely monitor the F3331?

A5: Yes, the system offers remote monitoring and control capabilities through Ethernet communication.

Q6: How do I perform firmware updates on the F3331?

A6: Firmware updates can be performed using the HIMA configuration software and connected directly to the controller.

Recommended Models from the Same Brand

| Model | Description | Safety Level | Dimensions | Weight | Input Voltage | Communication Ports |

|---|---|---|---|---|---|---|

| F3230 | General-purpose safety controller for industries | SIL 2 | 250 mm x 160 mm | 1.6 kg | 24 VDC | 2 x Ethernet |

| F5000 | Modular control system for critical safety | SIL 3 | 300 mm x 180 mm | 3.0 kg | 24 VDC | 4 x Ethernet |

| F6000 | Redundant safety controller for high-risk areas | SIL 3 | 320 mm x 220 mm | 3.5 kg | 24 VDC | 2 x RS485, 1 x Ethernet |

| F2131 | High-performance controller for process safety | SIL 3 | 200 mm x 120 mm | 1.3 kg | 24 VDC | 1 x RS485 |

| F3400 | Advanced fault-tolerant control system | SIL 3 | 280 mm x 160 mm | 2.5 kg | 24 VDC | 2 x Ethernet |

| F3330 | Compact safety controller for small-scale use | SIL 2 | 180 mm x 120 mm | 1.0 kg | 24 VDC | 1 x RS485 |

| F2132 | Modular safety system with advanced diagnostics | SIL 3 | 250 mm x 160 mm | 2.0 kg | 24 VDC | 2 x Ethernet |

| F3310 | Safety controller for high-volume processes | SIL 2 | 230 mm x 150 mm | 1.7 kg | 24 VDC | 2 x RS485 |

HIMA F3331 8-CHANNEL OUTPUT MODULE

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||