| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

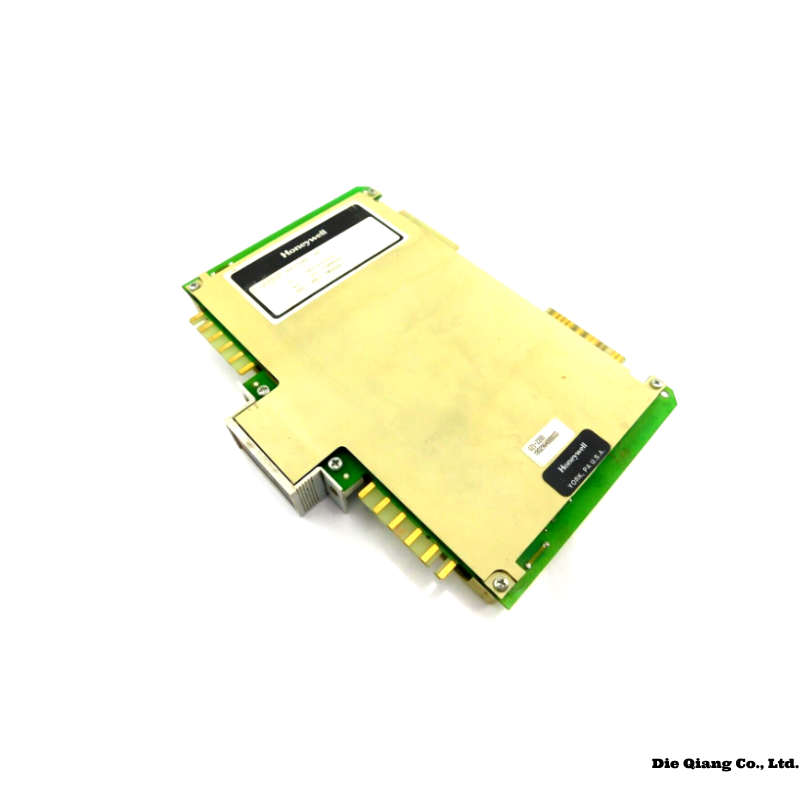

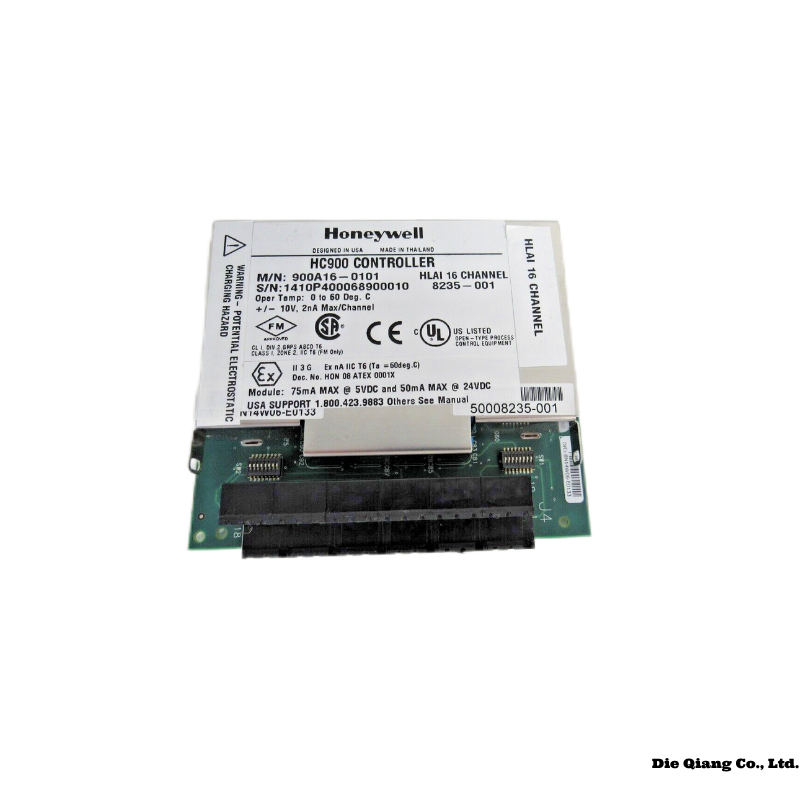

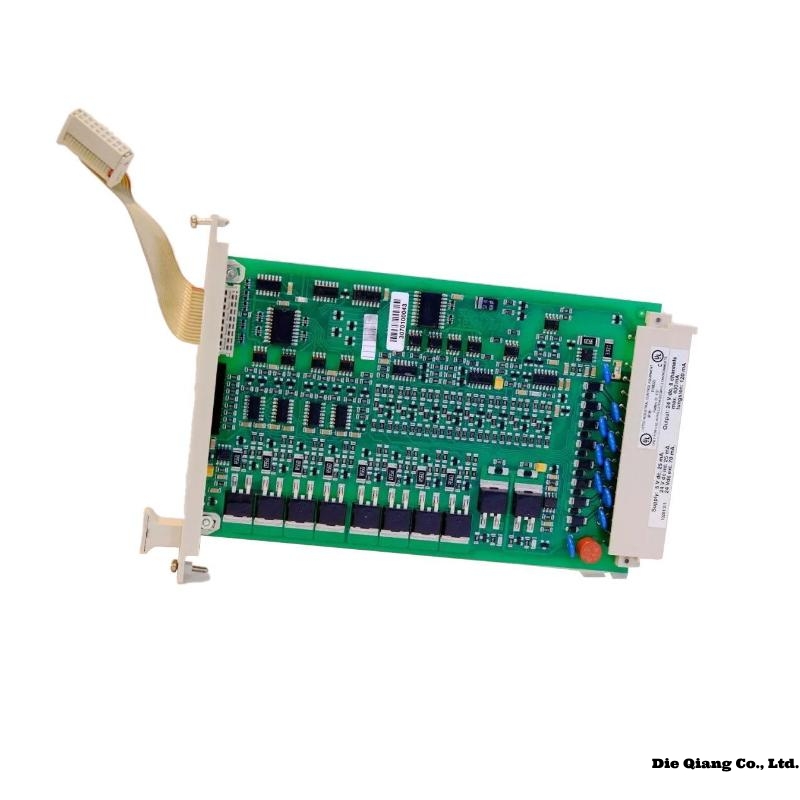

Honeywell 621-2200 – Product Overview

The Honeywell 621-2200 is a high-performance I/O module engineered for use in Honeywell’s robust TDC 3000 control systems. Designed to offer consistent performance, enhanced reliability, and ease of integration, the 621-2200 plays a pivotal role in industrial automation and process control systems. This module allows for seamless input and output operations within distributed control systems, ensuring optimal data acquisition and process responsiveness across critical industrial processes.

Known for its stable performance, the 621-2200 is constructed to meet the demands of rigorous industrial environments such as refineries, petrochemical plants, power generation facilities, and other heavy-duty manufacturing sectors. With its compact design, wide operating range, and compliance with global industry standards, the 621-2200 continues to be a preferred choice for control engineers and systems integrators worldwide.

Product Advantages

-

High Reliability

Built with premium-grade components and designed for long-term industrial use, ensuring minimal maintenance and high uptime. -

Seamless System Integration

Fully compatible with Honeywell’s TDC 3000 system, ensuring smooth integration with legacy and modern architectures. -

Versatile Input/Output Capability

Supports both analog and digital I/O configurations, offering flexibility in diverse application environments. -

Compact and Modular Design

Saves cabinet space and allows easy installation in dense configurations with other modules. -

Wide Operating Range

Operates reliably across a broad temperature range and under harsh environmental conditions. -

Long Product Lifecycle

Engineered for longevity with comprehensive manufacturer support, spare parts availability, and future-proof design.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | Honeywell 621-2200 |

| Product Type | I/O Module |

| System Compatibility | Honeywell TDC 3000 |

| Input Type | Digital / Analog (Configurable) |

| Channels | 16 Channels |

| Power Supply Voltage | 24 VDC |

| Operating Voltage Range | 18 to 30 VDC |

| Power Consumption | < 5 W |

| Communication Interface | Proprietary Honeywell Interface |

| Dimensions (H x W x D) | 150 mm x 35 mm x 120 mm |

| Weight | 0.45kg |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Mounting | DIN Rail / Rack Mount |

| Enclosure Type | Industrial Plastic with EMI Shielding |

| Certifications | CE, UL, CSA, RoHS |

Applications

The Honeywell 621-2200 module is widely used across numerous industrial sectors where process control and data acquisition are crucial. Key application areas include:

-

Oil & Gas Refineries

For real-time control of process variables such as pressure, temperature, and flow. -

Chemical and Petrochemical Plants

Ideal for precise monitoring and control of batch processing systems. -

Power Generation Facilities

Used in turbine control, boiler management, and energy distribution systems. -

Pharmaceutical Manufacturing

Supports GMP-compliant automation systems for production quality control. -

Pulp and Paper Industry

Enhances process efficiency in paper production and pulp processing units. -

Water and Wastewater Treatment

Provides robust automation in treatment plants to meet regulatory compliance.

Compatible Models

The 621-2200 is typically used in conjunction with the following Honeywell system components:

-

620-0036 – Analog Input Module

-

620-0081 – Digital Output Module

-

620-0088 – Communications Interface Module

-

621-9939 – Power Supply Module

-

621-9940 – I/O Chassis

-

621-9938 – Processor Module

These modules, when used together, deliver complete functionality within a TDC 3000 distributed control environment.

Installation Instructions

-

Power Off the System

Ensure the system is fully powered down before installation to avoid electric shock or data corruption. -

Insert Module into Chassis

Align the module with the designated slot in the I/O chassis or rack. Firmly slide the module until it clicks into place. -

Secure the Module

Use the provided locking mechanism or screw mounts to fasten the module securely into the chassis. -

Connect Wiring

Attach I/O wiring to the module terminals. Ensure proper labeling and shielded cables to minimize interference. -

Power On and Test

Re-energize the system and run diagnostic tests to confirm module recognition and proper function. -

Configure Software

Use Honeywell’s configuration tools to map the channels and set up signal types, thresholds, and alarms as required.

6 Related Models

| Model | Description | Channels | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|---|

| 621-9939 | Power Supply Module | N/A | 24 VDC | 150 x 35 x 110 | 420 g |

| 621-9940 | I/O Chassis | N/A | N/A | 300 x 100 x 200 | 3.2 kg |

| 620-0036 | Analog Input Module | 16 | 24 VDC | 150 x 35 x 120 | 450 g |

| 620-0081 | Digital Output Module | 16 | 24 VDC | 150 x 35 x 120 | 460 g |

| 620-0088 | Communication Interface Module | N/A | N/A | 150 x 35 x 120 | 430 g |

| 621-2100 | Advanced Control I/O Module | 16 | 24 VDC | 150 x 35 x 120 | 455 g |

8 Popular Honeywell Models

| Model | Description | Application | Voltage | Dimensions (mm) | Weight |

|---|---|---|---|---|---|

| CC-PDIL01 | Pulse Data Interface Module | Digital I/O | 24 VDC | 175 x 45 x 110 | 470 g |

| CC-TDOR11 | Digital Output Redundant Module | Safety Systems | 24 VDC | 175 x 45 x 115 | 480 g |

| CC-TFB811 | Fieldbus Interface Module | Field Device Integration | 24 VDC | 170 x 45 x 110 | 460 g |

| CC-PCF901 | Control Processor | Central Control Unit | 24 VDC | 180 x 50 x 120 | 520 g |

| CC-TAIX01 | Analog Input Module | Process Monitoring | 24 VDC | 175 x 45 x 110 | 450 g |

| CC-PDOD01 | Digital Output Module | Actuator Control | 24 VDC | 175 x 45 x 110 | 455 g |

| CC-TCF901 | Control Firewall Module | Network Security | N/A | 180 x 45 x 120 | 500 g |

| 621-2200 | General Purpose I/O Module | TDC 3000 Systems | 24 VDC | 150 x 35 x 120 | 450 g |

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the Honeywell 621-2200?

A1: The 621-2200 serves as an I/O module for interfacing field devices with the Honeywell TDC 3000 system. It handles signal input and output from field instrumentation for process control.

Q2: Is the 621-2200 compatible with all versions of the TDC 3000 system?

A2: Yes, the module is fully compatible with all standard TDC 3000 configurations and supports backward integration with older systems.

Q3: What are the power requirements for this module?

A3: The module operates on a 24 VDC power supply with an acceptable range of 18 to 30 VDC, consuming less than 5 watts during normal operation.

Q4: Can the 621-2200 be hot-swapped during system operation?

A4: It is not recommended to hot-swap the module. The system should be powered down before installation or replacement to avoid data loss or equipment damage.

Q5: What type of I/O channels does the 621-2200 support?

A5: The module supports both digital and analog channels, and configuration is done through Honeywell’s system tools depending on process requirements.

Q6: Is the 621-2200 resistant to harsh environmental conditions?

A6: Yes, it is designed for industrial use, capable of operating in temperatures from -20°C to +60°C and in environments with high humidity.

Honeywell 621-2200 OUTPUT MODULE

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||