| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

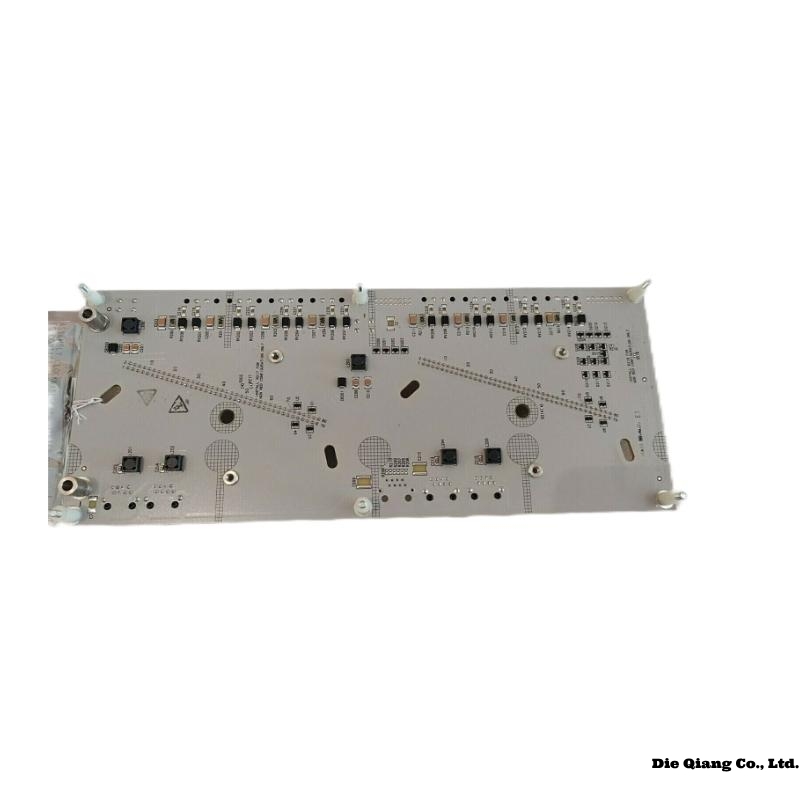

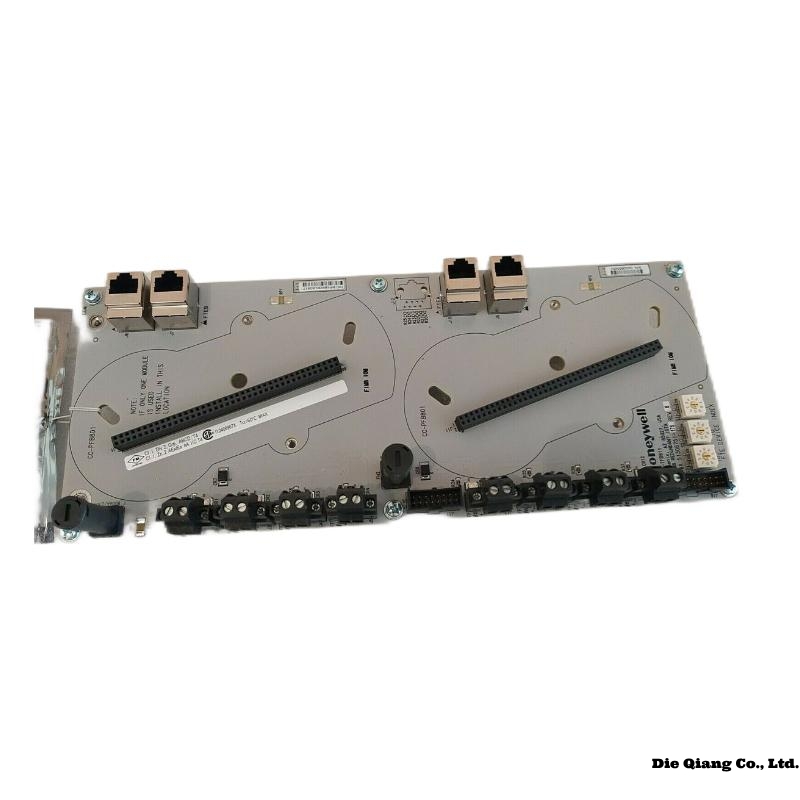

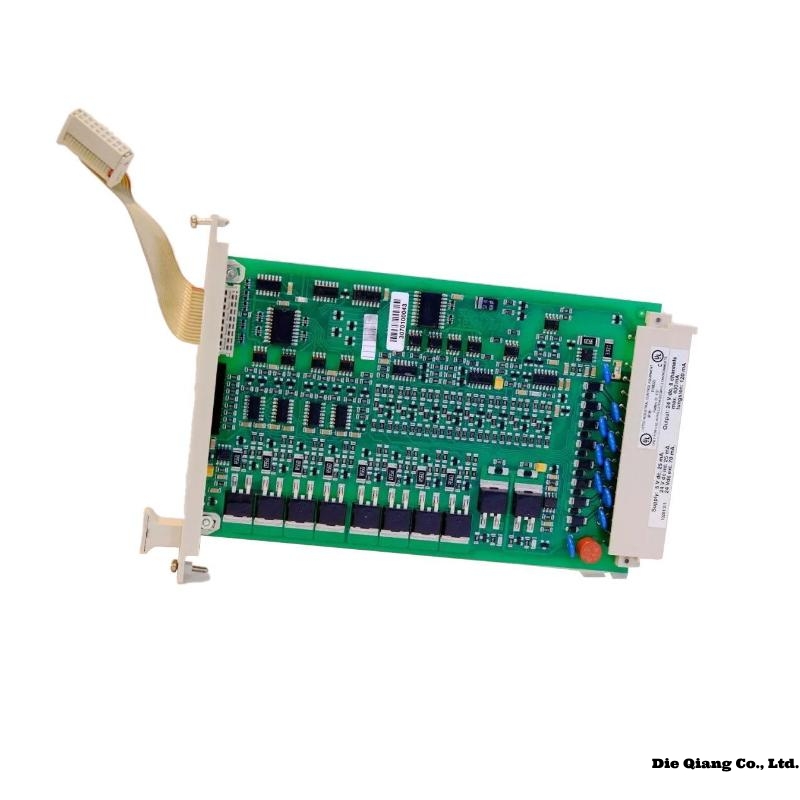

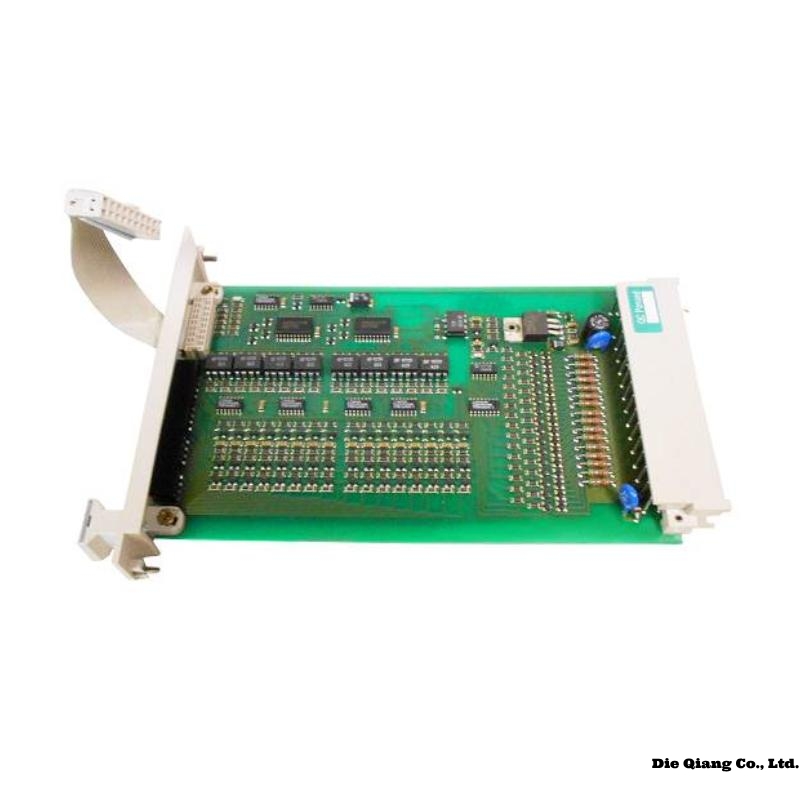

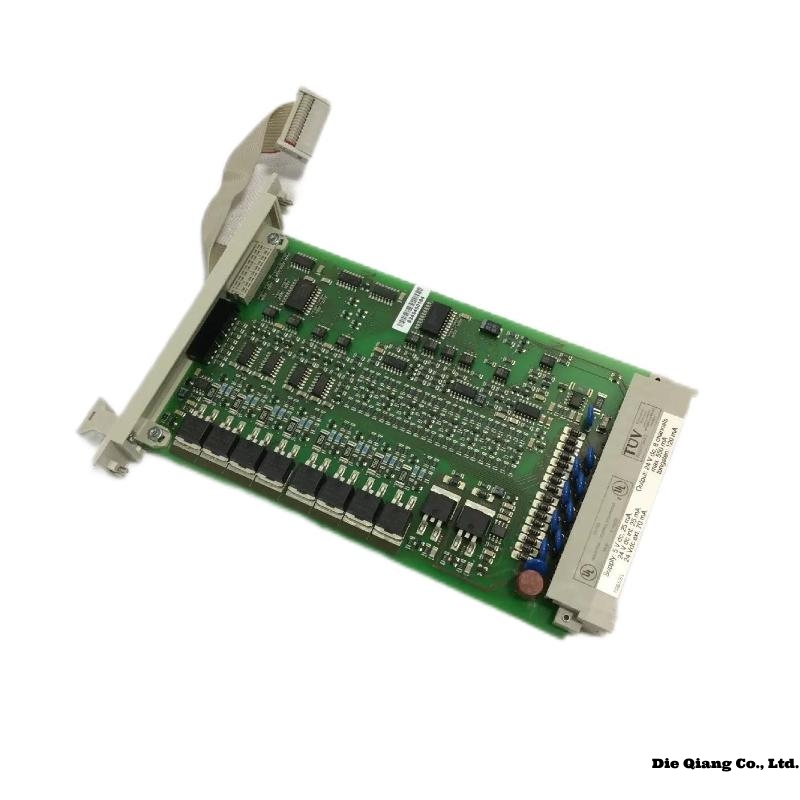

Honeywell CC-TFB811 Detailed Product Documentation

Product Introduction

The Honeywell CC-TFB811 is an advanced Field Bus I/O module, part of the Experion PKS (Process Knowledge System) architecture, designed to deliver high-performance process control and seamless integration across industrial automation systems. Built with Honeywell’s expertise in control technology, this module enables reliable data acquisition and control from field devices, ensuring robust operation in critical environments. It provides a direct interface between the controller and field instruments via Foundation Fieldbus protocol, optimizing plant efficiency, reducing wiring complexity, and enhancing system flexibility.

This module is specifically engineered to meet the demanding requirements of industries such as oil & gas, petrochemical, chemical processing, power generation, and water treatment facilities. Its rugged design, easy installation, and advanced diagnostics make it a preferred choice for modern distributed control systems (DCS).

Product Advantages

-

High Reliability: Engineered for harsh industrial environments, offering long operational life and stable performance under extreme conditions.

-

Seamless Integration: Native support for Foundation Fieldbus communication ensures smooth integration with a wide range of field devices.

-

Reduced Wiring Complexity: Simplifies installation and maintenance by significantly reducing wiring needs compared to conventional I/O systems.

-

Advanced Diagnostics: Built-in health monitoring and diagnostics capabilities help in predictive maintenance and early fault detection.

-

Scalability: Easily scalable, allowing expansion as the control system grows, providing flexibility for future upgrades.

-

Energy Efficiency: Optimized power consumption contributes to overall plant energy savings.

-

User-Friendly Maintenance: Hot-swappable design allows for module replacement without system shutdown, minimizing downtime.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | CC-TFB811 |

| Communication Protocol | Foundation Fieldbus H1 |

| Number of Channels | 2 H1 channels |

| Power Supply Voltage | 24 VDC nominal (range: 19.2 to 30 VDC) |

| Power Consumption | 3.2 W typical |

| Dimensions | 290 mm x 120 mm x 52 mm |

| Weight | 0.85 kg |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Mounting | DIN rail or panel mount |

| Certifications | CE, CSA, ATEX, IECEx |

| EMC Compliance | EN 61326-1 |

| Hot Swappable | Yes |

| Enclosure Rating | IP20 |

| Diagnostic Functions | Advanced diagnostics for field devices |

| Firmware Upgrade | Supported (online upgrade) |

Product Applications

The Honeywell CC-TFB811 is widely adopted in various industries for process automation and control applications. Typical use cases include:

-

Oil & Gas: Upstream and downstream operations, including refineries and offshore platforms.

-

Chemical Processing: For precise control and monitoring of chemical reactions and processes.

-

Power Generation: Monitoring and controlling boiler and turbine systems in power plants.

-

Water and Wastewater Management: Supervising and controlling treatment processes and distribution networks.

-

Pharmaceutical Manufacturing: Ensuring regulatory compliance and process accuracy in drug production.

-

Pulp and Paper Industry: Facilitating control of complex processes such as bleaching and pulping.

Compatible Models for System Integration

The CC-TFB811 module is designed to operate in conjunction with the following Honeywell models for a complete control system:

-

CC-PUI800: Universal Process Interface Module

-

CC-TDIL01: Digital Input Low Voltage Module

-

CC-TDOR01: Digital Output Relay Module

-

CC-TAIX01: Analog Input Module

-

CC-TAOX01: Analog Output Module

-

CC-PCF901: Field Control Processor Module

These components work together to deliver a robust and integrated control solution tailored to complex industrial environments.

Installation Instructions

-

Safety First: Ensure all power sources are disconnected before installation.

-

Mounting: Secure the CC-TFB811 on a standard DIN rail or mount it directly on a panel using appropriate fasteners.

-

Wiring: Connect the Fieldbus cables to the designated terminals, ensuring polarity is correct.

-

Power Connection: Supply 24 VDC to the power terminals, adhering to the voltage specifications.

-

System Integration: Connect the module to the control network and configure it using the Honeywell Experion system software.

-

Device Configuration: Use system tools to assign addresses and configure communication parameters for connected field devices.

-

Testing: Power up the system and perform initial diagnostics to verify correct installation and communication.

-

Commissioning: Finalize the setup by conducting loop checks and functional tests in accordance with project requirements.

Related Models (with Specifications)

| Model Number | Description | Voltage | Dimensions (mm) | Weight (kg) | Channels |

|---|---|---|---|---|---|

| CC-PFB401 | Profibus Fieldbus Module | 24 VDC | 290 x 120 x 52 | 0.82 | 2 |

| CC-TDIL01 | Digital Input Module | 24 VDC | 290 x 120 x 52 | 0.80 | 16 |

| CC-TDOR01 | Digital Output Relay Module | 24 VDC | 290 x 120 x 52 | 0.85 | 16 |

| CC-TAIX01 | Analog Input Module | 24 VDC | 290 x 120 x 52 | 0.83 | 8 |

| CC-TAOX01 | Analog Output Module | 24 VDC | 290 x 120 x 52 | 0.84 | 8 |

| CC-PCF901 | Field Control Processor | 24 VDC | 290 x 120 x 52 | 0.95 | N/A |

Popular Honeywell Models (with Specifications)

| Model Number | Description | Voltage | Dimensions (mm) | Weight (kg) | Application |

|---|---|---|---|---|---|

| CC-PUI800 | Universal Process Interface Module | 24 VDC | 290 x 120 x 52 | 0.90 | Process input/output control |

| CC-PCF901 | Field Control Processor | 24 VDC | 290 x 120 x 52 | 0.95 | Central control processing |

| CC-TDIL01 | Digital Input Module | 24 VDC | 290 x 120 x 52 | 0.80 | Digital signal acquisition |

| CC-TDOR01 | Digital Output Relay Module | 24 VDC | 290 x 120 x 52 | 0.85 | Digital signal output |

| CC-TAIX01 | Analog Input Module | 24 VDC | 290 x 120 x 52 | 0.83 | Analog signal acquisition |

| CC-TAOX01 | Analog Output Module | 24 VDC | 290 x 120 x 52 | 0.84 | Analog signal output |

| CC-PAIH01 | Analog Input High-Level Module | 24 VDC | 290 x 120 x 52 | 0.86 | High-level analog input |

| CC-PAOH01 | Analog Output High-Level Module | 24 VDC | 290 x 120 x 52 | 0.88 | High-level analog output |

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the Honeywell CC-TFB811?

A1: The CC-TFB811 functions as a Fieldbus I/O module, providing communication and data exchange between field devices and the control system through Foundation Fieldbus protocol.

Q2: Can the CC-TFB811 module be replaced without shutting down the system?

A2: Yes, it supports hot-swapping, allowing for module replacement without interrupting system operations.

Q3: What is the recommended power supply voltage for this module?

A3: The recommended nominal power supply voltage is 24 VDC, with an acceptable range between 19.2 to 30 VDC.

Q4: What types of field devices can be connected to the CC-TFB811?

A4: Any Foundation Fieldbus-compatible device, such as transmitters, actuators, and valve positioners, can be connected.

Q5: How can I perform firmware upgrades for the CC-TFB811?

A5: Firmware upgrades can be done online through the Honeywell Experion system, minimizing downtime and ensuring continuous operation.

Q6: What certifications does the Honeywell CC-TFB811 have?

A6: The module is certified by CE, CSA, ATEX, and IECEx, ensuring compliance with international safety and performance standards.

Honeywell CC-TFB811 51306751-175 FIELDBUS INTERFACE IOTA

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||