| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

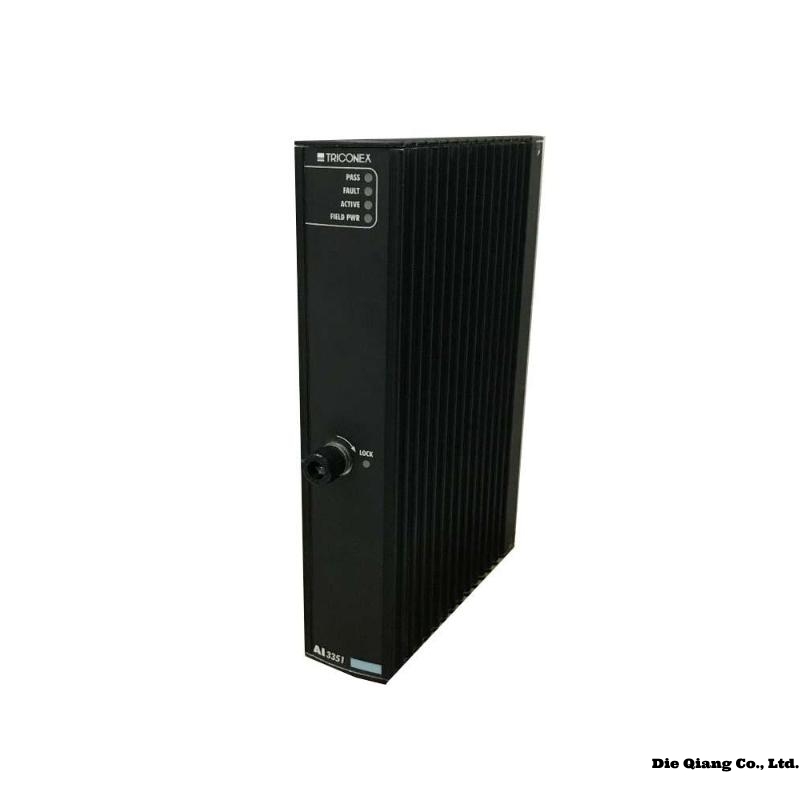

Triconex 3004 Product Overview

The Triconex 3004 is a high-performance safety instrumented system (SIS) module designed for critical control applications in industrial environments. It is part of the Triconex Tricon series, known for its robust fault-tolerant architecture and reliability in demanding sectors such as oil & gas, power generation, and chemical processing.

The module ensures seamless integration within safety systems, providing real-time monitoring and control to prevent hazardous conditions. Its triple-modular redundancy (TMR) technology guarantees maximum uptime and minimizes the risk of system failure.

Product Advantages

- Triple-Modular Redundancy (TMR) – Ensures fault tolerance by processing data across three independent channels.

- High Availability – Redundant components and hot-swappable design reduce downtime.

- Wide Operating Temperature Range – Suitable for harsh industrial environments.

- Certified Safety Compliance – Meets IEC 61508 and SIL 3 standards.

- Easy Integration – Compatible with existing Triconex systems and third-party interfaces.

- Long Lifespan – Designed for extended operational use with minimal maintenance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | Triconex 3004 |

| Dimensions (HxWxD) | 250 x 200 x 45 mm |

| Weight | 1.2 kg |

| Input Voltage | 24V DC (±10%) |

| Power Consumption | 15W |

| Operating Temp. | -40°C to +70°C |

| Communication | Ethernet, RS-485 |

| Certifications | SIL 3, IEC 61508, ATEX (optional) |

| Redundancy | Triple-Modular Redundancy (TMR) |

Applications

The Triconex 3004 is widely used in:

- Oil & Gas – Emergency shutdown systems (ESD), fire & gas detection.

- Power Plants – Turbine control, boiler protection.

- Chemical Processing – Safety interlocks, pressure relief systems.

- Pharmaceuticals – Batch process safety management.

- Mining – Hazardous environment monitoring.

Compatible Products

The Triconex 3004 works seamlessly with:

- Triconex 3805E – Power Supply Module

- Triconex 4351B – Communication Module

- Triconex 3625 – Digital Input Module

- Triconex 3721 – Analog Output Module

- Triconex 3503E – Main Processor

Installation Instructions

- Mounting – Secure the module in a DIN rail or panel-mounted enclosure.

- Wiring – Connect power and I/O cables as per the wiring diagram.

- Power-Up – Verify voltage compatibility before energizing.

- Configuration – Use TriStation software for parameter setup.

- Testing – Perform a diagnostic test to ensure proper functionality.

- Documentation – Record installation details for maintenance.

Recommended Related Models (Same Series)

| Model | Function | Voltage | Dimensions | Weight |

|---|---|---|---|---|

| Triconex 3008 | Enhanced TMR Processor | 24V DC | 160x130x85 mm | 1.5 kg |

| Triconex 3626 | High-Density Digital Input | 24V DC | 150x120x80 mm | 1.1 kg |

| Triconex 3722 | Analog Input Module | 24V DC | 150x120x80 mm | 1.0 kg |

| Triconex 3806E | Redundant Power Supply | 120V AC | 200x150x90 mm | 2.0 kg |

| Triconex 4352B | Advanced Comm Module | 24V DC | 150x120x80 mm | 1.2 kg |

| Triconex 3504E | Secondary Processor | 24V DC | 160x130x85 mm | 1.4 kg |

Popular Triconex Models (Other Series)

| Model | Function | Voltage | Dimensions | Weight |

|---|---|---|---|---|

| Triconex 1105 | Safety Controller | 24V DC | 180x140x90 mm | 1.8 kg |

| Triconex 2401 | Communication Gateway | 24V DC | 200x150x100 mm | 2.2 kg |

| Triconex 4009 | Remote I/O Module | 24V DC | 150x120x80 mm | 1.1 kg |

| Triconex 5008 | High-Speed Logic Solver | 24V DC | 160x130x85 mm | 1.6 kg |

| Triconex 2103 | Compact Safety System | 24V DC | 140x110x70 mm | 1.0 kg |

| Triconex 7201 | Vibration Monitoring Module | 24V DC | 150x120x80 mm | 1.3 kg |

| Triconex 6005 | Fault-Tolerant I/O | 24V DC | 160x130x85 mm | 1.5 kg |

| Triconex 8102 | HMI Interface Module | 24V DC | 200x150x90 mm | 2.0 kg |

Frequently Asked Questions (FAQ)

Q1: What is the lifespan of the Triconex 3004?

A1: The module is designed for 15+ years of operation with proper maintenance.

Q2: Can the Triconex 3004 operate in explosive environments?

A2: Yes, with optional ATEX certification, it can be used in hazardous areas.

Q3: Is the Triconex 3004 compatible with non-Triconex systems?

A3: Limited compatibility exists via standard protocols like Modbus or OPC.

Q4: How often should diagnostics be performed?

A4: Quarterly diagnostics are recommended for critical applications.

Q5: What is the lead time for replacement units?

A5: Typically 4-6 weeks, depending on stock availability.

Q6: Can the Triconex 3004 be upgraded firmware-wise?

A6: Yes, firmware updates are released periodically for enhanced features.

Triconex 3004 Main Processor Module

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

![]()

![]()

![]()

![]()