| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

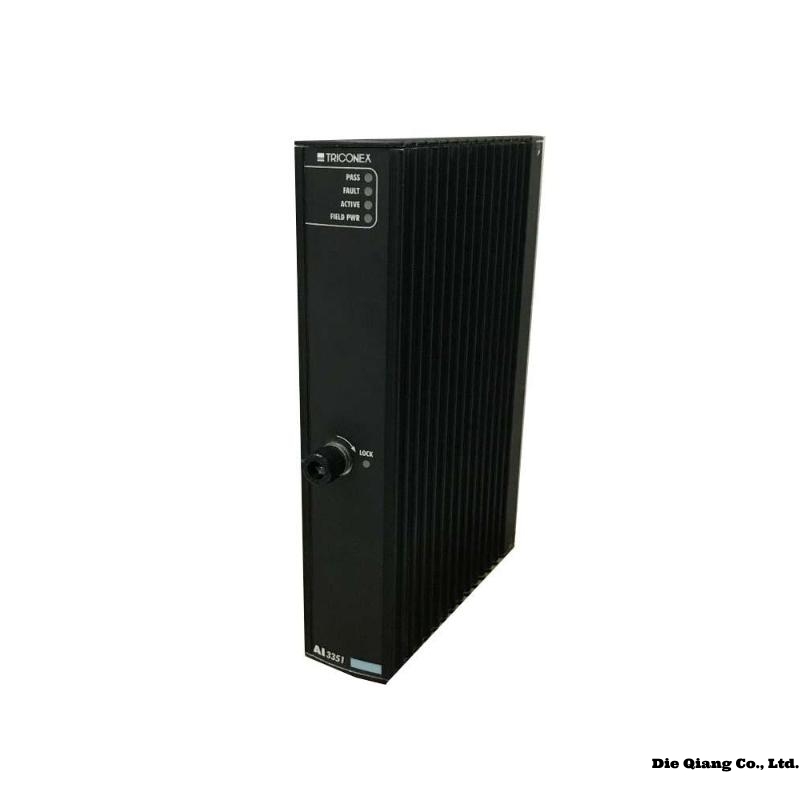

Triconex 3009 Product Overview

The Triconex 3009 is part of the Triconex safety system, designed to provide highly reliable, fault-tolerant, and scalable solutions for critical process control systems. As part of the Triconex family, the 3009 model is engineered to meet the stringent requirements of safety instrumented systems (SIS) and industrial control processes where safety, uptime, and performance are essential.

Product Advantages

-

High Reliability: The Triconex 3009 offers triple modular redundancy (TMR), which ensures continuous system operation even if one of the modules fails, making it a highly reliable choice for critical applications.

-

Scalability: It is designed to scale seamlessly with your system, supporting a wide range of applications from small to large-scale processes.

-

Safety and Compliance: The system complies with international safety standards, such as IEC 61508, IEC 61511, and ISO 13849, making it suitable for safety-critical environments.

-

Fault Tolerance: With a fault-tolerant architecture, the Triconex 3009 guarantees system operation without interruption, even under failure conditions, offering improved operational continuity.

-

Ease of Integration: The Triconex 3009 is designed for easy integration with existing control systems, reducing the complexity of implementation and minimizing the total cost of ownership.

Technical Specifications

| Parameter | Value |

|---|---|

| Dimensions | 228 x 160 x 75 mm |

| Weight | 1.6 kg |

| Operating Voltage | 24 VDC ± 10% |

| Power Consumption | 15 W |

| Operating Temp. | -20°C to +60°C |

| Storage Temp. | -40°C to +85°C |

| Humidity | 5% to 95% RH |

| Protection Rating | IP20 |

| Communication | Modbus, Ethernet, Profibus |

Applications

The Triconex 3009 is ideal for a variety of applications that require safety and control. These include:

-

Oil and Gas: For pipeline monitoring and emergency shutdown systems (ESD).

-

Chemical and Petrochemical: For hazardous materials handling and process safety.

-

Power Generation: For turbine protection, reactor safety, and plant shutdown systems.

-

Pharmaceutical: To ensure compliance with stringent safety standards in manufacturing processes.

Compatible Models

The Triconex 3009 can be used in conjunction with several other Triconex products for enhanced functionality and scalability. Below are some compatible models:

| Model | Description | Main Features |

|---|---|---|

| Triconex 3000 | A basic module for standard control systems | TMR architecture, hot-swappable, easy integration |

| Triconex 3030 | Advanced safety controller | Increased I/O support, enhanced diagnostics |

| Triconex 3008 | Expansion unit for Triconex 3009 | Provides additional I/O, supports redundancy |

| Triconex 3500 | High-performance safety system | Greater I/O capacity, high-speed communication |

| Triconex 3800 | Safety system for hazardous areas | Designed for extreme environmental conditions |

| Triconex 4000 | Modular safety system with advanced features | Integrated diagnostics, extended scalability |

Installation Instructions

-

Prepare the Installation Area: Ensure the installation environment is clean and free from any interference. The Triconex 3009 should be installed in a location with an ambient temperature between -20°C and +60°C.

-

Mounting: Secure the module on a DIN rail using the provided mounting brackets. Ensure that there is adequate space around the module for proper ventilation.

-

Wiring: Connect the input and output wiring as specified in the user manual. Ensure proper grounding to avoid electrical issues.

-

Power Up: Apply power to the system, ensuring that the voltage is within the specified range (24 VDC ± 10%).

-

System Configuration: Once powered up, configure the system through the software interface. Follow the instructions in the manual to set up the necessary safety parameters and communication protocols.

-

Testing: Conduct a series of tests to verify the system’s operation and ensure that all safety protocols are functional.

Frequently Asked Questions (FAQ)

-

Q: What safety certifications does the Triconex 3009 have?

A: The Triconex 3009 meets international safety standards such as IEC 61508, IEC 61511, and ISO 13849 for safety instrumented systems. -

Q: Can the Triconex 3009 be used in hazardous locations?

A: Yes, it is suitable for use in hazardous locations when installed with proper enclosures that meet the necessary safety classifications. -

Q: How does the Triconex 3009 handle module failures?

A: The Triconex 3009 uses triple modular redundancy (TMR) to ensure continuous operation even if one module fails. -

Q: What is the power requirement for the Triconex 3009?

A: The system operates on 24 VDC ± 10% and has a power consumption of 15 W. -

Q: Is the Triconex 3009 compatible with existing control systems?

A: Yes, the Triconex 3009 is designed to integrate easily with existing control systems using standard communication protocols like Modbus, Ethernet, and Profibus. -

Q: What kind of maintenance is required for the Triconex 3009?

A: The system requires regular diagnostics and firmware updates to ensure it operates at optimal performance. Periodic testing and verification of safety protocols are also recommended.

Recommended Related Models from Triconex

| Model | Description | Main Features | Key Parameters |

|---|---|---|---|

| Triconex 3000 | Basic safety controller | TMR architecture, scalable | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 3030 | Advanced safety controller | Enhanced diagnostics, I/O support | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 3008 | Expansion unit | Additional I/O | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 3500 | High-performance system | High-speed communication | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 3800 | For hazardous areas | Extreme conditions ready | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 4000 | Modular safety system | High scalability, diagnostics | Voltage: 24 VDC, Temp: -20°C to 60°C |

Popular Triconex Models

| Model | Description | Main Features | Key Parameters |

|---|---|---|---|

| Triconex 3600 | Advanced safety controller | Redundant systems, diagnostics | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 3400 | Compact safety system | Reliable, easy integration | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 4000 | Modular system | Scalable, high-performance | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 4100 | High-end controller | Fast response times, diagnostics | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 4500 | Enhanced modular system | Advanced I/O, redundancy | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 4600 | High-capacity controller | Extensive I/O, diagnostics | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 4200 | Compact I/O system | High reliability, scalable | Voltage: 24 VDC, Temp: -20°C to 60°C |

| Triconex 3700 | Flexible control unit | Customizable for various tasks | Voltage: 24 VDC, Temp: -20°C to 60°C |

Triconex 3009 Main Processor

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

![]()

![]()

![]()

![]()