| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

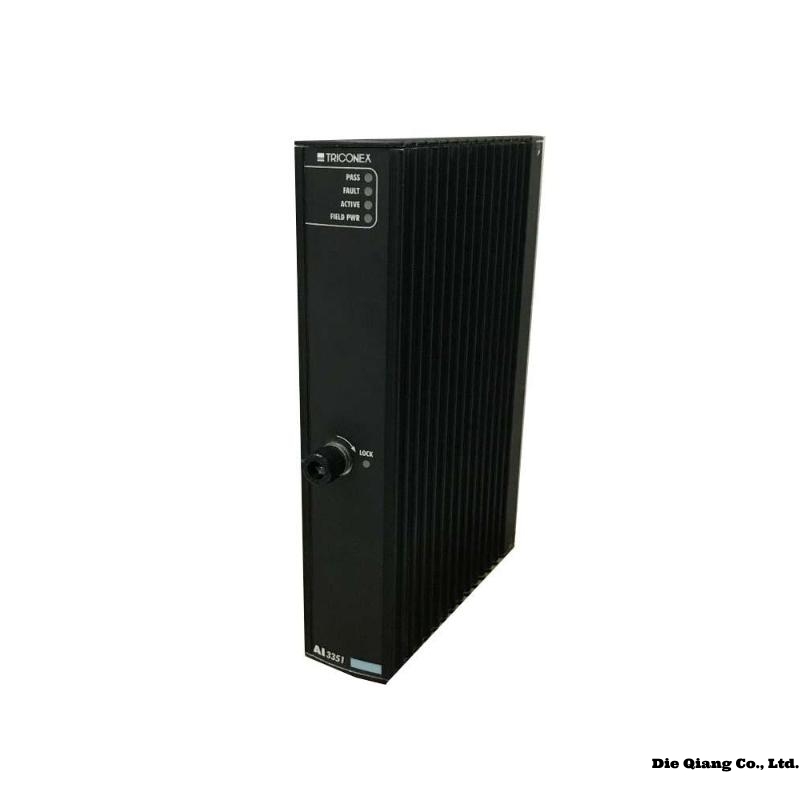

Product Overview of Triconex 3511

The Triconex 3511 is part of the Tricon™ system, which is an advanced, high-performance, and safety-focused controller designed for industrial process applications. This device is renowned for its reliability and safety, making it ideal for use in critical control systems where safety and continuous operation are paramount.

The Triconex 3511 provides excellent fault tolerance and can ensure the safety of industrial processes by detecting and responding to faults in real-time. It is widely used in industries like oil & gas, chemical processing, power generation, and other critical environments where process integrity and safety are key concerns.

Advantages of Triconex 3511

-

High Availability: The Triconex 3511 features a fault-tolerant architecture, ensuring that the system remains operational even in the event of component failure.

-

Safety Integrity: The product complies with the highest safety standards, offering SIL 3 (Safety Integrity Level) certification. This makes it suitable for use in applications requiring the highest levels of safety.

-

Scalability: The system can be expanded to meet the needs of growing operations without compromising performance.

-

Real-Time Monitoring and Diagnostics: It offers real-time diagnostics, ensuring immediate detection of faults and facilitating rapid corrective actions.

-

Redundancy: The Triconex 3511 supports full redundancy, ensuring the system is always running smoothly and avoiding any downtime.

-

Ease of Integration: It integrates seamlessly with existing systems and supports a wide variety of protocols, enhancing flexibility in different industrial environments.

-

Long-Term Support: As part of the Triconex family, the 3511 benefits from long-term technical support and a large installed base, ensuring reliability and continuous updates.

Technical Specifications

| Parameter | Value |

|---|---|

| Dimensions | 270 x 46 x 253 mm |

| Weight | 3.03kg |

| Voltage | 24 V DC |

| Power Consumption | 15W |

| Operating Temperature | -10°C to 60°C |

| Mounting | DIN Rail or Panel Mount |

| Safety Integrity Level (SIL) | SIL 3 (Safety Integrity Level 3) |

| Input/Output Channels | 16 Input / 16 Output Channels |

| Communication Protocol | Modbus, Profibus, Ethernet |

| Processor Speed | 2.0 GHz |

Product Applications

The Triconex 3511 is used in various critical and safety-critical applications:

-

Oil & Gas Industry: For monitoring and controlling safety systems in offshore platforms, refineries, and pipeline systems.

-

Chemical Processing: Used in hazardous environments where stringent safety standards must be maintained.

-

Power Generation: Provides reliable control for power plants, including nuclear and renewable energy facilities.

-

Mining & Metals: Ensures safe and efficient operation in mining plants and metal manufacturing processes.

-

Water and Wastewater Treatment: Monitors critical processes in water purification and distribution.

-

Pharmaceutical Manufacturing: Ensures compliance with safety and process requirements in pharmaceutical production.

Models Compatible with Triconex 3511

Here are other models from the same series or related ones that can be used in conjunction with the Triconex 3511:

| Model | Description |

|---|---|

| Triconex 3008 | Small I/O module for basic process control. |

| Triconex 3805 | Redundant controller for critical safety systems. |

| Triconex 3803 | Advanced analog input/output module for precise control. |

| Triconex 3802 | Digital input/output module with high-density configuration. |

| Triconex 3602 | Communication module for integration into larger systems. |

| Triconex 3601 | Redundant communication module for system redundancy. |

Popular Triconex Models

In addition to the Triconex 3511, here are other popular models within the Triconex brand:

| Model | Description | Key Parameters |

|---|---|---|

| Triconex 3510 | Safety controller for process industries | SIL 3, 16 I/O channels, 24V DC, 6.3 kg |

| Triconex 3501 | Basic controller for industrial control | SIL 2, 12 I/O channels, 24V DC, 5.1 kg |

| Triconex 4001 | High-performance safety system | SIL 3, 32 I/O channels, 24V DC, 8.0 kg |

| Triconex 3000 | Safety PLC with advanced diagnostics | SIL 3, 8 I/O channels, 24V DC, 4.0 kg |

| Triconex 3201 | Modular system for critical applications | SIL 2, 16 I/O channels, 24V DC, 6.0 kg |

| Triconex 3804 | Communication expansion module | SIL 3, supports multiple protocols, 3.5 kg |

| Triconex 3806 | Analog input/output module | SIL 3, 16 channels, 24V DC, 6.3 kg |

| Triconex 3809 | Digital input/output module | SIL 2, 16 channels, 24V DC, 5.9 kg |

FAQ

Q1: What is the safety integrity level (SIL) of the Triconex 3511?

A1: The Triconex 3511 is certified with SIL 3, which is the highest safety integrity level for industrial safety systems, ensuring it meets the most stringent safety requirements.

Q2: What types of communication protocols are supported by the Triconex 3511?

A2: The Triconex 3511 supports Modbus, Profibus, and Ethernet protocols, allowing for flexible integration into a variety of industrial systems.

Q3: What is the voltage requirement for the Triconex 3511?

A3: The Triconex 3511 operates at 24 V DC, which is a common voltage requirement for industrial controllers.

Q4: How do I mount the Triconex 3511?

A4: The Triconex 3511 can be mounted on a DIN rail or panel mount, offering flexibility depending on the installation environment.

Q5: What is the temperature range for operating the Triconex 3511?

A5: The Triconex 3511 operates within a temperature range of -10°C to 60°C, making it suitable for a wide range of industrial environments.

Q6: Is the Triconex 3511 suitable for use in hazardous environments?

A6: Yes, the Triconex 3511 is designed for use in hazardous environments such as oil and gas, chemical processing, and power generation facilities. It meets the stringent safety standards required for these industries.

Triconex 3511 Pulse Input Module

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

![]()

![]()

![]()

![]()