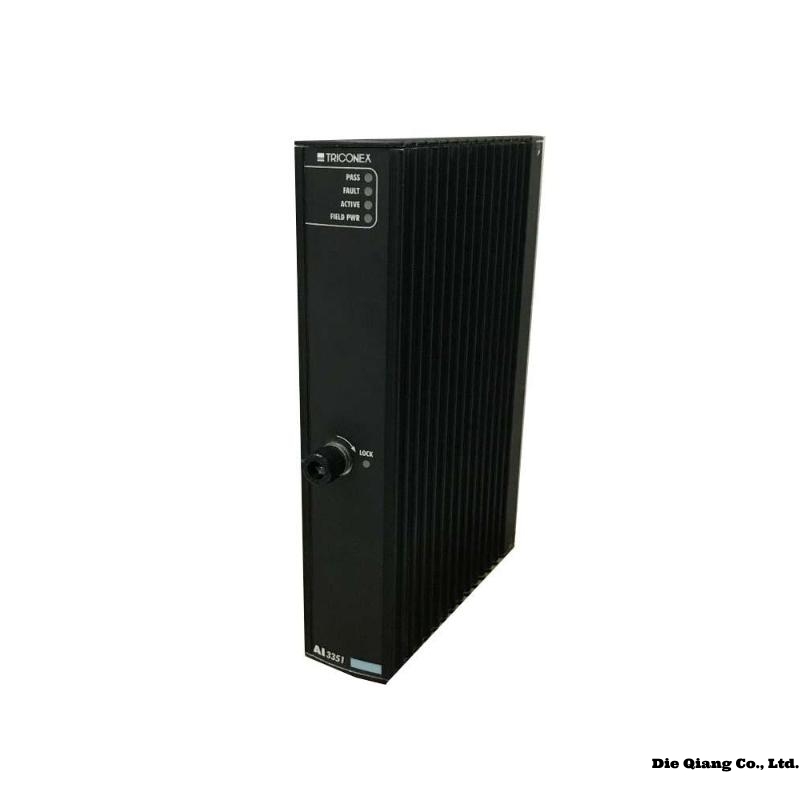

Triconex 3617E Product Introduction

The Triconex 3617E is a safety-related control system designed for critical applications that require high reliability and safety. It is part of the Triconex series, which is known for providing reliable and redundant control in hazardous environments. The 3617E model is tailored to meet industry standards and provides a combination of integrated safety, control, and process automation functions. It supports high-performance capabilities while ensuring strict compliance with safety regulations.

This device is typically used in industries such as chemical processing, oil and gas, and power generation where safety and operational continuity are paramount. The Triconex 3617E offers a scalable and flexible platform, ensuring that users can adapt it to their specific operational needs.

Product Advantages

-

High Availability and Reliability: The Triconex 3617E features a triple modular redundancy (TMR) architecture that ensures continuous operation even in the event of failures, making it highly reliable.

-

Safety Compliance: Designed to meet functional safety standards, it adheres to IEC 61508 and IEC 61511 for process safety management, making it suitable for SIL 3 (Safety Integrity Level 3) applications.

-

Scalability: The modular design allows for flexible configurations, accommodating the varying needs of different processes and industries.

-

Redundant Communication: It comes equipped with redundant communication channels that ensure uninterrupted data flow even during communication failures.

-

Easy Integration: The system can easily integrate with existing control systems and supports various industrial protocols, ensuring seamless operation.

-

Long Lifecycle: Built with durability in mind, the Triconex 3617E offers a long lifecycle, reducing maintenance needs and downtime.

Technical Specifications

| Parameter | Specification |

|---|---|

| Dimensions | 228 x 160 x 75 mm |

| Weight | 2.27 kg |

| Input Voltage | 24V DC |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Communication Protocols | Modbus, TCP/IP, Ethernet, Profibus |

| Power Consumption | 3W max. |

| Safety Integrity Level (SIL) | SIL 3 |

| Redundancy | Triple Modular Redundancy (TMR) |

Product Application

The Triconex 3617E is widely used in industries where safety and process control are critical. Some of the key applications include:

-

Chemical Processing: Used for controlling hazardous processes and ensuring safety during chemical reactions.

-

Oil and Gas: Provides reliable safety functions for drilling, production, and transportation operations.

-

Power Generation: Applied in the control and monitoring of safety-critical systems like turbine and generator protection.

-

Refining: Used in refineries for process automation and safety management, reducing the risk of accidents.

Its versatility in handling complex, hazardous, and safety-critical processes makes it a preferred choice in high-risk environments.

Compatible Models for Use with Triconex 3617E

The Triconex 3617E can be used in conjunction with the following models for extended functionality and integration within the same Triconex series:

-

Triconex 3615E – A similar safety controller but with a higher processing capacity.

-

Triconex 3620 – A system controller designed for larger applications with more complex safety requirements.

-

Triconex 3621 – Features redundant architecture for higher reliability in safety applications.

-

Triconex 3800 – A high-performance safety solution for critical processes with increased input/output support.

-

Triconex 3510 – For applications requiring functional safety at SIL 2 level.

-

Triconex 3508 – A simplified controller for smaller, less complex safety tasks.

-

Triconex 3619 – An enhanced version for larger process applications requiring increased scalability and control.

-

Triconex 3671E – A safety module designed to protect against hazardous process conditions.

Installation Instructions

-

Mounting: Ensure the system is mounted in a clean, dry, and temperature-controlled environment to avoid damage and performance degradation.

-

Wiring: Properly wire the device, ensuring all connections are secure. Use appropriately rated cables for power and communication lines.

-

Configuration: Use the dedicated software tools for the initial configuration, ensuring that all parameters are set according to the system requirements.

-

Testing: Conduct functional testing and verify the integrity of all safety-related operations before deploying the system in a live environment.

-

Grounding: Properly ground the system to prevent electrical noise interference and ensure stable operation.

-

Calibration: Ensure that all input and output devices connected to the Triconex 3617E are calibrated for accurate measurement and control.

Frequently Asked Questions (FAQs)

Q1: What is the primary function of the Triconex 3617E?

A1: The Triconex 3617E is designed to provide safety-related control in critical industrial applications, ensuring process safety and system reliability.

Q2: Can the Triconex 3617E be used in hazardous environments?

A2: Yes, it is suitable for hazardous environments such as chemical plants, oil and gas refineries, and power generation facilities where safety is a top priority.

Q3: How is the Triconex 3617E different from other safety controllers?

A3: The Triconex 3617E offers triple modular redundancy (TMR), making it more reliable and fault-tolerant compared to standard controllers.

Q4: Is the Triconex 3617E easy to integrate into existing systems?

A4: Yes, the Triconex 3617E supports multiple communication protocols, allowing it to integrate seamlessly with existing control systems.

Q5: What certifications does the Triconex 3617E have?

A5: The Triconex 3617E meets the functional safety standards of IEC 61508 and IEC 61511, ensuring its suitability for SIL 3 applications.

Q6: How do I troubleshoot the Triconex 3617E?

A6: Troubleshooting can be done using diagnostic tools and the integrated software suite. It’s also important to ensure proper wiring and connection integrity before starting troubleshooting procedures.

Related Models (Same Brand and Series)

| Model | Specification |

|---|---|

| Triconex 3615E | SIL 3, 24V DC, TMR architecture, 3W max. power consumption |

| Triconex 3620 | SIL 3, enhanced input/output support, modular design |

| Triconex 3621 | SIL 3, redundant architecture, integrated diagnostics |

| Triconex 3800 | SIL 3, supports larger applications, extended I/O |

| Triconex 3510 | SIL 2, compact controller for smaller safety tasks |

| Triconex 3508 | SIL 2, simplified design for less complex systems |

| Triconex 3619 | SIL 3, scalable system for large process applications |

| Triconex 3671E | SIL 3, specialized for hazardous process conditions |