| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

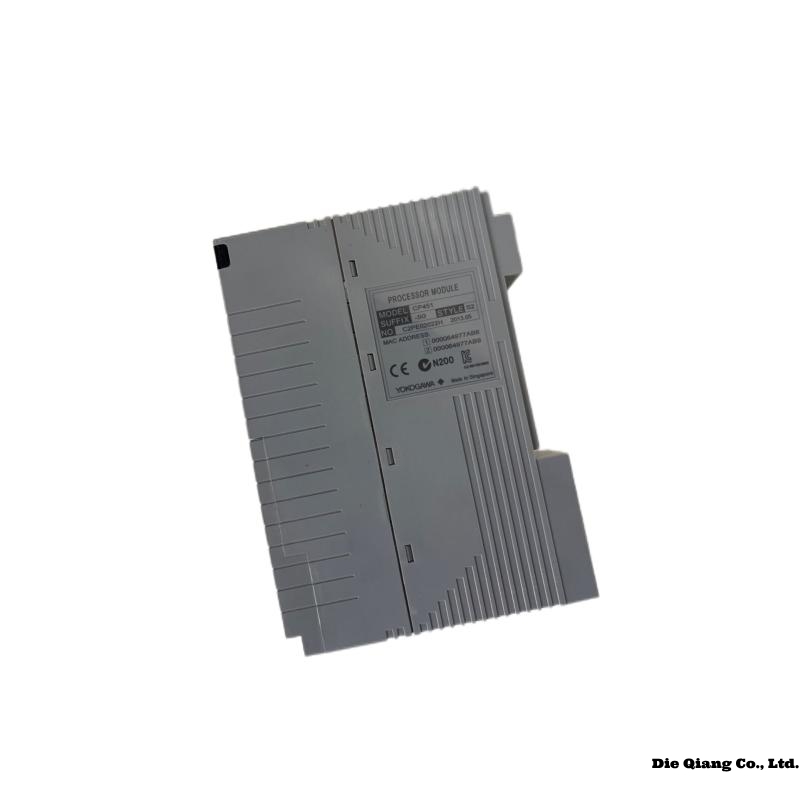

Yokogawa CP451-50 Detailed Product Documentation

Product Introduction

The Yokogawa CP451-50 is a high-performance CPU module designed for integration within the Yokogawa CENTUM VP Distributed Control System (DCS). This advanced CPU unit is engineered to deliver exceptional processing speed, robust reliability, and superior system availability for demanding industrial automation environments. Specifically crafted to manage complex control algorithms and large volumes of I/O data, the CP451-50 stands out with its efficient architecture, energy-saving operation, and seamless scalability.

Designed in alignment with Yokogawa’s renowned standards of precision and durability, the CP451-50 plays a critical role in ensuring plant safety and operational excellence. The module supports continuous plant operations with its redundant configurations, enabling fail-safe performance in mission-critical applications such as oil & gas, petrochemicals, power generation, and pharmaceuticals.

Its compact form factor and advanced diagnostics make the CP451-50 a reliable choice for operators who demand top-tier performance and minimum downtime in complex control environments.

Product Advantages

-

High-Speed Data Processing

Equipped with a high-performance processor, the CP451-50 handles large-scale control tasks with minimal latency, ensuring real-time responsiveness. -

Robust System Redundancy

Supports full redundancy for CPU, power supply, and communication paths, greatly enhancing system availability and fault tolerance. -

Scalable Architecture

Flexible configuration options allow seamless expansion as plant requirements evolve, making it a future-proof investment. -

Energy Efficiency

Engineered for low power consumption without compromising performance, helping reduce overall operational costs. -

Advanced Diagnostics & Self-Monitoring

Integrated diagnostics continuously monitor system health, providing early warnings and preventive maintenance alerts. -

Compliance with Global Standards

Designed in accordance with international certifications and safety standards (CE, UL, CSA), suitable for worldwide deployment. -

User-Friendly Engineering Tools

Compatible with Yokogawa’s engineering environment for simplified configuration, monitoring, and maintenance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | CP451-50 |

| Processor Type | High-performance 64-bit processor |

| Memory Capacity | 256 MB main memory |

| Dimensions | 98 × 47.5 × 136 mm |

| Weight | 0.8 kg |

| Input Voltage | 24 V DC ±10% |

| Power Consumption | Approx. 8 W |

| Operating Temperature | 0 to 55°C |

| Storage Temperature | -20 to 70°C |

| Relative Humidity | 5 to 95% RH (non-condensing) |

| Communication Ports | Vnet/IP, Ethernet, Serial |

| Installation Method | Mounted on system I/O base plate |

| Certifications | CE, UL, CSA, KC, ATEX |

| Diagnostic Functions | Built-in self-diagnostics |

| System Redundancy Support | Yes (Full redundancy) |

| Compatible Software | CENTUM VP R6 and later |

Product Applications

-

Oil & Gas Production Facilities

Managing complex upstream and downstream processes with high reliability. -

Petrochemical Plants

Supporting continuous and batch process operations with superior control performance. -

Power Generation Plants

Ensuring stable power supply through precise process control and fast response to load changes. -

Pharmaceutical Manufacturing

Meeting strict regulatory requirements for batch control and documentation. -

Water Treatment Plants

Automating and optimizing water purification and distribution processes. -

Steel and Metal Processing

Delivering high-speed control for rolling mills, furnaces, and material handling.

Compatible Models

-

Yokogawa AL451-10 (Advanced I/O Module)

-

Yokogawa PW482-10 (Power Supply Module)

-

Yokogawa AMN11 (Analog Input Module)

-

Yokogawa AAI141-H00 (High-Speed Analog Input Module)

-

Yokogawa ADV151-P00 (Digital Input Module)

-

Yokogawa ANB10D (Field Control Unit Base Plate)

-

Yokogawa Vnet/IP Network Switch (System Communication)

Installation Instructions

-

Preparation

Ensure all power sources are turned off. Verify compatibility with system base plates and ensure all installation tools are available. -

Mounting

Securely install the CP451-50 onto the designated system I/O base plate. Ensure firm connections to avoid vibration-related faults. -

Wiring

Connect the power supply cables according to the polarity indicated. Link communication ports (Vnet/IP, Ethernet) properly. -

Verification

Perform visual inspection to ensure all wiring and module connections are correctly implemented. -

Power-Up

Gradually restore power to the system. Monitor status LEDs for initial diagnostic confirmation. -

Configuration

Using Yokogawa’s engineering software, assign the appropriate node addresses and load the configuration files. -

Final Testing

Execute system diagnostics and validate module operation through the engineering console.

Recommended Related Models (Same Series/Compatible)

| Model Number | Description | Dimensions (mm) | Weight | Voltage |

|---|---|---|---|---|

| CP451-10 | Standard CPU Module | 98 × 47.5 × 136 | 0.8 kg | 24 V DC |

| CP461-50 | High-Performance CPU Module | 98 × 47.5 × 136 | 0.9 kg | 24 V DC |

| PW482-10 | Power Supply Module | 100 × 50 × 140 | 1.0 kg | 24 V DC |

| AL451-10 | Advanced I/O Module | 98 × 47.5 × 136 | 0.7 kg | 24 V DC |

| ANB10D | Field Control Unit Base Plate | 250 × 300 × 50 | 2.5 kg | N/A |

| AAI141-H00 | High-Speed Analog Input Module | 100 × 50 × 140 | 0.9 kg | 24 V DC |

Popular Yokogawa Models (Cross-Brand Hot Models)

| Model Number | Description | Dimensions (mm) | Weight | Voltage |

|---|---|---|---|---|

| FCN-RTU | Remote Terminal Unit | 130 × 65 × 160 | 1.2 kg | 24 V DC |

| YHC4150X | Fieldbus Handheld Communicator | 240 × 120 × 50 | 1.5 kg | Battery Operated |

| DX2020 | Paperless Recorder | 144 × 144 × 200 | 2.0 kg | 100-240 V AC |

| AXG1A | Magnetic Flowmeter | Custom sizes | Varies | 24 V DC |

| ADMAG AXF | Magnetic Flowmeter | Custom sizes | Varies | 24 V DC |

| EJX110A | Differential Pressure Transmitter | 115 × 120 × 150 | 2.4 kg | 10.5–42 V DC |

| FLXA202 | pH/ORP Analyzer | 144 × 144 × 198 | 2.1 kg | 100-240 V AC |

| TDLS8000 | Tunable Diode Laser Analyzer | 610 × 460 × 280 | 16 kg | 100-240 V AC |

FAQs (Frequently Asked Questions)

Q1: What is the primary function of the CP451-50 module?

A1: The CP451-50 functions as the central processing unit for the Yokogawa CENTUM VP system, handling real-time process control, data acquisition, and communication with field devices.

Q2: Can the CP451-50 operate in extreme temperature environments?

A2: Yes, the CP451-50 is designed to operate reliably in ambient temperatures ranging from 0°C to 55°C, with a storage temperature capability of -20°C to 70°C.

Q3: Is redundancy supported by the CP451-50?

A3: Absolutely. The CP451-50 supports full redundancy for CPU, communication, and power supply to ensure continuous operation even in the event of a hardware failure.

Q4: What software is compatible with the CP451-50?

A4: The CP451-50 is fully compatible with Yokogawa’s CENTUM VP R6 or later versions, allowing seamless system configuration and monitoring.

Q5: How is the CP451-50 installed in a control system?

A5: Installation involves mounting the CPU module onto the system I/O base plate, connecting the power and communication lines, configuring the system software, and performing verification diagnostics.

Q6: Can I expand the system with additional modules?

A6: Yes, the CP451-50 supports system expansion. You can add various I/O modules and communication interfaces to scale according to the requirements of your process plant.

Yokogawa CP451-50 Processor Module

| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8615980777398 | |||||||

| +8615980777398 | ||||||||

| +8615980777398 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||